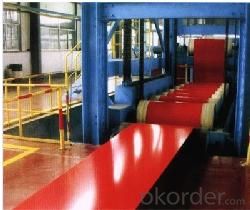

Prepainted GI Steel Coil / PPGI / PPGL Color Coated Galvanized Steel Sheet In Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS, JIS,ASTM,GB,AISI | Grade: | galvanized steel coil | Thickness: | 0.15MM-1.5MM*600-1250MM

|

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | 0.15MM-1.5MM*600-1250MM |

| Type: | Steel Coil, Steel Coil | Technique: | Cold Rolled, Cold Rolled | Surface Treatment: | Galvanized, Galvanized |

| Application: | sanwichpanel roofing | Special Use: | High-strength Steel Plate, High-strength Steel Plate,Wear Resistant Steel | Width: | 600-1250mm, 600-1250mm or customizable |

| Length: | 3000-6000mm, 3000-6000mm | Color: | RR, RAL color | Zinc coated: | 30g/m2- 275g/m2 |

Packaging & Delivery

| Packaging Details: | excellent steel seaworthy export package with water and rustproof paper inside. |

| Delivery Detail: | 7-30 days |

Prepainted GI Steel Coil / PPGI / PPGL Color Coated Galvanized Steel Sheet In Coil

| NAME | PPGI/PPGL | GALVANIZED | GALVALUME/ALUZINC |

| CERTIFICATE | ISO9001 | ||

| STANDARD | GB/T-12754 | GB/T-2518 | GB/T-14798 |

| JIS G 3312 | JIS G 3302 | JIS G 3321 | |

| EN 10169 | EN 10142/10427 EN10346 | EN 10215 | |

| ASTM A755 | ASTM A653 | ASTM A792 | |

| GRADE | SGCC | SS GRADE33-80 | GRADE33-80 |

| DX51D+Z | SGCC | SGLCC | |

| DX53D+Z | SGCH | SGLCD | |

| SGCH | SGCD1-SGCD3 | SGLCDD | |

| CGCD1-CGCD3 | SGC340-SGC570 | SGLC400-SGLC570 | |

| CGC340-CGC570 | SGCC | SZACC | |

| DX51D+Z | SZACH | ||

| DX53D+Z | SZAC340R | ||

| MODEL NO | 0.15MM-0.7MM*600-1250MM | (0.13-1.2)*600-1250MM | 0.13MM-1.2MM*600-1250MM |

| ZINC OR AZ Coating | 60-275g/m2 | 60-275g/m2 | 60-150g/m2 |

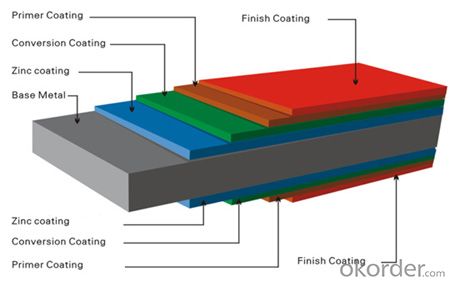

| Painting | top paint 16-25um back paint 7-10 | ||

| TYPE | Steel coil | Steel coil | Steel coil |

| Steel sheets/plates | Steel sheets/plates | Steel sheets/plates | |

| Corrugated steel sheets/plates | Corrugated steel sheets/plates | Corrugated steel sheets/plates | |

| TECHNIQUE | Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

| -galvalume /galvanized | - galvanized | -galvalume /Aluzinc | |

| -PPGI/PPGL | |||

| SURFACE TREATMENT | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

| Chromate treatment /chromate-free treatment /untreated unoile/oiled, | Chromate treatment /chromate-free treatment /untreated unoile/oiled, | ||

| TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, | TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, | ||

| Coating,color | Coating | ||

| APPLICATION | Structural use,roofing,corrugated roofing,commercial use,household appliance, industry,family | ||

| SPECIAL APPLICATION | Wear resistant steel,high-strength-steel plate | ||

- Q: Just wondering how good are forge steel screw drivers, tool boxes(organisers) and pliers are, as screw fix are having a january sale, and looking to add to my tool collection. Thanks in advance

- forged steel is a trick to get people like you who know nothing of steel to think of a blacksmith hammering away at a anvil making great tools. Not to say they are bad they are probably fine. but forged just means it was made when the steel was hot, it says nothing of the quality of steel in the process. however whenever steel is forged it will be stronger than the same product made out the same steel, but shaped by machining process.

- Q: What minerals are mixed to make steel?

- It depends on the type of steel that you want. For example- A cold drawn carbon steel spring wire consists of Carbon,Silicon,Manganese,sulphur potassium. If you want to make an alloy steel you can also add chrome,vanadium , nickel etc. It depends on the combinations and percentages of each used.

- Q: How do steel coils withstand extreme temperatures?

- Steel coils are able to withstand extreme temperatures due to their unique composition and manufacturing process. Steel, the primary material used in coils, is an alloy of iron and carbon that possesses excellent thermal properties. Its high melting point, which can reach up to 2,500 degrees Fahrenheit (1,370 degrees Celsius), allows it to remain structurally stable under intense heat. Furthermore, steel coils are often subjected to a process called annealing, which involves heating the steel to a specific temperature and then slowly cooling it down. This annealing process helps relieve internal stresses within the steel, making it more resistant to thermal expansion and contraction. By reducing the presence of internal defects, annealing also enhances the steel's overall strength and durability, allowing it to better withstand extreme temperatures. Moreover, steel coils are often coated with protective layers to provide additional resistance against temperature variations. These coatings, such as galvanized or zinc coatings, act as a barrier between the steel and the external environment. They help prevent oxidation, corrosion, and other forms of degradation that can occur when exposed to extreme heat or cold. In summary, steel coils are able to withstand extreme temperatures due to the inherent properties of steel, the annealing process that relieves internal stresses, and the protective coatings that provide an extra layer of resistance. These factors work together to ensure that steel coils remain structurally stable and maintain their performance even in the harshest temperature conditions.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- can't freeze it but ya can make it very cold

- Q: full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

- Q: Correct me if I am wrong, but steel is an alloy between iron and carbon. Does the carbon in the steel stops the iron from rusting or corroding? Also what is the difference between mild steel and stainless steel?

- Mild steel is an alloy. It is the most common form of steel. Mild steel (a so-called carbon steel) is a general term for a range of low carbon (a maximum of about 0.3%) steels that have good strength and can be bent, worked or can be welded into an endless variety of shapes for uses from vehicles (like cars and ships) to building materials. The carbon does not stop the material rusting or corroding. In addition to iron, carbon, and chromium, modern stainless steel may also contain other elements, such as nickel, niobium, molybdenum, and titanium. Nickel, molybdenum, niobium, and chromium enhance the corrosion resistance of stainless steel. It is the addition of a minimum of 12% chromium to the steel that makes it resist rust, or stain 'less' than other types of steel. The chromium in the steel combines with oxygen in the atmosphere to form a thin, invisible layer of chrome-containing oxide, called the passive film. The sizes of chromium atoms and their oxides are similar, so they pack neatly together on the surface of the metal, forming a stable layer only a few atoms thick. If the metal is cut or scratched and the passive film is disrupted, more oxide will quickly form and recover the exposed surface, protecting it from oxidative corrosion.

- Q: How are steel coils used in the manufacturing of metal furniture?

- Steel coils are an essential component in the manufacturing of metal furniture. These coils are typically made from high-quality steel, which provides strength, durability, and stability to the furniture. The first step in using steel coils in the manufacturing process is to cut them into the desired length and width. This is done using specialized machinery and tools, ensuring precise and accurate dimensions for the furniture components. Once the coils are cut, they are then shaped and formed into various furniture parts such as chair frames, table bases, or cabinet structures. The coils can be bent, welded, or manipulated to create the desired shapes and designs. After the shaping process, the steel coils are further processed to enhance their aesthetic appeal and protection against corrosion. This involves sanding, polishing, and applying protective coatings or finishes to give the furniture a smooth and attractive surface. In addition to providing structural support and visual appeal, steel coils also contribute to the overall functionality of metal furniture. They offer excellent load-bearing capacity, ensuring that the furniture can withstand weight and pressure without bending or breaking. Moreover, steel coils make metal furniture more resistant to wear and tear, making it suitable for both indoor and outdoor use. They can withstand harsh weather conditions, making them ideal for patio furniture or outdoor seating arrangements. Overall, steel coils are indispensable in the manufacturing of metal furniture, playing a crucial role in providing strength, durability, and aesthetic appeal. Their versatility and reliability make them a preferred choice for furniture manufacturers worldwide.

- Q: Can steel coils be coated with polymer?

- Yes, steel coils can be coated with polymer.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

Send your message to us

Prepainted GI Steel Coil / PPGI / PPGL Color Coated Galvanized Steel Sheet In Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords