Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color,

then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. 2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• Excellent corrosion resistance

• Excellent weather resistance

• High strength

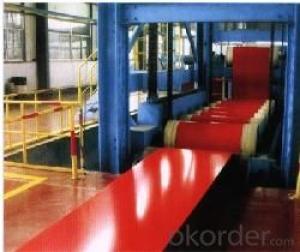

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including pickling, oiling, galvanizing, and painting. Pickling involves removing surface impurities and scale through the use of acid solutions. Oiling is a process where a thin layer of oil is applied to the coil surface to prevent rust and improve handling. Galvanizing involves coating the steel with a layer of zinc to provide corrosion resistance. Painting is another surface treatment where a protective layer of paint is applied onto the coil surface to enhance durability and aesthetics.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes can include scratches, pits, rust, oil stains, and uneven coating. Scratches can occur during handling and transportation, and they can affect the overall appearance and performance of the steel coil. Pits are small depressions on the surface caused by a variety of factors such as impurities in the steel or improper processing. Rust can form when the steel coil is exposed to moisture or corrosive environments, and it can weaken the structural integrity of the material. Oil stains can occur if the coil is not properly cleaned before or after processing, leaving unsightly marks on the surface. Uneven coating can happen during the application of protective coatings or paints, resulting in areas with different levels of protection and aesthetics. It is important to address these defects to ensure the quality and durability of the steel coil for its intended applications.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: I was wondering what material most common motorcycle gas tanks are made out of? is it steel? stainless steel? aluminum? what are the advantages and disadvantages or each?

- Aluminum Motorcycle Gas Tank

- Q: How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as a primary raw material for the fabrication of various structural components such as frames, bodies, and chassis. These coils are typically processed through cutting, bending, welding, and shaping techniques to create the necessary parts that provide strength, durability, and stability to construction machinery.

- Q: I noticed that Jimmy Page finger picked on a steel acoustic guitar on quite a few tracks like Stairway to heaven and other ones and I was wondering how did he do it? I know it is more difficult to finger pick on a steel acoustic because of the rougher steel strings and higher tensions so I was wondering do they make specific strings that allow for fingerstyle playing? Also Randy Rhoads finger picked a steel acoustic on Dee along with a Classical guitar.

- I've seen people put the guitar on a table and pick it that way. This is fairly common method in playing Bluegrass and country songs. There are finger picks that are used. These are finger rings with claws.

- Q: I'm going to buy a guitar for beginners and i wondered what strings are better steel or nylon?

- Musical type speaks volumes on the subject of this problem. Folks that want high quantity shall be unhappy with unamplified nylon string guitars. From my point of view, the elemental difference between steel and nylon is that this: steel strings ring and nylon strings resonate. The volume produced via steel is quite often a lot bigger than nylon however, to my mind-set, the sound resonance produced with the aid of the wooden of your guitar is essentially masked by steel strings. In case you have a decently made guitar (generally, around a thousand dollars and up), the sound interaction between the wooden and the strings in a nylon guitar is magical across the whole frequency range. With a steel string guitar, the sound produced via the vibrating string overpowers the timber resonance at all but low frequencies. In my view, i'll take a nylon string guitar any day for the sensitivity won from the interplay between timber and vibrating string.

- Q: Can steel coils be coated with polymer?

- Yes, steel coils can be coated with polymer. The polymer coating provides protection against corrosion, improves durability, and enhances the appearance of the steel coils.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils are used in the production of electronic devices for various purposes, such as creating magnetic fields, providing structural support, and acting as conductors in transformers and inductors. These coils are typically wound around a core material, such as ferrite or laminated iron, to enhance their magnetic properties and improve their performance in electronic circuits.

- Q: Im looking at some knives and am wandering if they use good steel one is this case knife and its 54 dollars Do they use good steel or not Iv never had a good experience with Case but am wandering if they use good steel now? if you all have any other recommendations let me hear them I got my Selection from here so any others wont hurt. so basic break down does case use good steel know?

- Vintage Case Knives

Send your message to us

Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords