Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:DX51d SGCC DX52d

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Hot Dipped

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Dx51d

Thickness:0.3mm

Width:1250mm

Top Paint:15+5

Back Paint:5-7

ID:508mm

Coil Weight:3-8 Tons

Zinc Coating:50g-250g/Psm

Gloss:65%-80%

Feedback:Within 24 Hours

Export Markets:Global

Additional Info.

Packing:Export Standard Package

Standard:AISI, ASTM, BS, DIN, GB, JIS

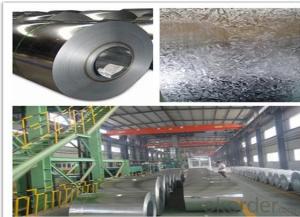

Origin:Shandong

HS Code:7210701000

Production Capacity:150, 000tons/Year

Product Description

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 30 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

Why Us:

1. ISO, BV, CE, SGS approved

2. Competitive price and quality from our own factory

3. Efficient service team online for 24 hours

4. Smooth production ability(50000tons/month)

5. Quick delivery and standard exporting package

6. Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc

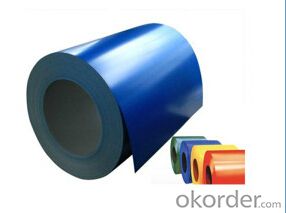

| Name | 0.3mm Thickness PPGI Prepainted Galvanized Steel Coil |

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 3-8 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000mm-1500mm |

| Zinc Coating | Z50-Z275G/psm |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation |

- Q: How are steel coils priced in the market?

- Steel coils are priced in the market based on various factors such as the current demand and supply levels, raw material costs, production and transportation expenses, market competition, and overall market conditions. Additionally, quality, size, and specifications of the steel coils also play a role in determining their pricing.

- Q: How are steel coils used in the manufacturing of agricultural structures?

- Due to their durability, strength, and versatility, steel coils play a vital role in the manufacturing of agricultural structures. Typically made from high-quality steel, these coils are utilized in various ways throughout the construction process of agricultural buildings such as barns, silos, and storage facilities. One primary application of steel coils in agricultural structures is seen in the creation of the building's framework. The coils are unwound, cut into specific lengths, and then bent, shaped, and welded together to form the structural framework. The exceptional strength and rigidity of steel coils make them an ideal choice for withstanding the heavy loads and harsh environmental conditions commonly found in agricultural settings. Moreover, steel coils are also used in the production of different components and accessories for agricultural structures. These coils can be transformed into panels, roofing sheets, doors, and windows, which are essential elements in constructing agricultural buildings. The ability to customize the shape, size, and thickness of the steel coils allows for flexibility in design and ensures that the finished structure meets the specific requirements of the agricultural application. Furthermore, steel coils play a crucial role in providing protection and safety within agricultural structures. They are employed in fabricating fencing and gates, creating secure boundaries and preventing unauthorized access. Steel coils can also reinforce the walls and floors of the building, enhancing its stability and durability. Additionally, steel coils offer excellent resistance to corrosion, which is particularly important in agricultural structures due to exposure to moisture, chemicals, and other corrosive elements. Their durability ensures that the structure remains intact and functional for an extended period, thereby reducing maintenance and replacement costs. In conclusion, steel coils are indispensable in the manufacturing of agricultural structures. Their strength, durability, versatility, and resistance to corrosion make them an ideal choice for constructing the framework, components, and accessories of these buildings. By utilizing steel coils in the manufacturing process, agricultural structures can be built to withstand heavy loads, harsh environmental conditions, and provide long-lasting protection for agricultural operations.

- Q: How are steel coils used in the production of agricultural structures?

- Steel coils are used in the production of agricultural structures as they are the primary material for manufacturing various components like beams, columns, and trusses. These coils are typically shaped, cut, and welded to form the framework for buildings, barns, silos, and other agricultural structures. The strength and durability of steel make it an ideal choice, ensuring that the structures can withstand harsh weather conditions and support heavy loads, making them essential for the agricultural industry.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. However, it is typically measured in millimeters or inches, ranging from a few tenths of a millimeter to several millimeters.

- Q: Got small (.177) bb gun for fun with my son...From the manual:'Steel shot will fire at a higher velocity then lead shot with with the same muzzle energy. As a result, more caution is required when using steel shot because of a greater hazard of ricochet. Lead, because of its lower velocity, usually has less penetrating power and is less likely to ricochet.'Are you agree with that? ;)

- steel is made of iron mainly (and carbon) its density is 7.86 g/cm? approximately. and lead has density=11.4 g/cm?. so, if have same volume and shape steel will have less mass and thus will have greater velocity for same muzzle energy. I agree the manual. for more information on ricochet

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled during transportation by using specialized equipment such as cranes or forklifts with padded forks. They are secured with steel bands or other restraints to prevent movement and damage. Additionally, they are usually loaded onto flatbed trucks or shipping containers with proper cushioning and support to minimize the risk of impact or deformation during transit.

- Q: What are the common coil widths available for steel coils?

- The common coil widths available for steel coils typically range from 24 inches to 72 inches, with 36 inches and 48 inches being the most common options.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils lies in the manufacturing process and the resulting properties of the steel. Hot rolled steel coils are produced by heating the steel above its recrystallization temperature, which allows for greater malleability and ductility. This process also results in a rough surface finish. On the other hand, cold rolled steel coils are manufactured by rolling the steel at room temperature, resulting in a smoother and more refined surface finish. Cold rolling also increases the strength and hardness of the steel. Overall, hot rolled steel coils are more suitable for applications where flexibility and formability are important, while cold rolled steel coils are ideal for applications requiring high strength and a smooth surface finish.

- Q: Can steel coils be used in marine environments?

- Although steel coils can be utilized in marine environments, it is crucial to take necessary precautions to avoid corrosion. Given that steel is susceptible to corrosion when exposed to moisture and saltwater, which are commonly found in marine environments, it is imperative to employ protective measures on the steel coils. One such method is treating them with protective coatings like galvanization or painting to establish a shield between the steel and the corrosive elements. Moreover, regular maintenance and inspections should be conducted to detect any signs of corrosion and promptly address them to prevent further harm. By implementing these measures, steel coils can be effectively employed in marine environments while minimizing the risk of corrosion and ensuring their durability and performance.

- Q: What are the common coil processing equipment used in the industry?

- Some common coil processing equipment used in the industry include coil slitting machines, coil winding machines, coil straighteners, coil feeders, and coil cradles. These machines are used to cut, shape, and feed metal coils in various manufacturing processes.

Send your message to us

Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords