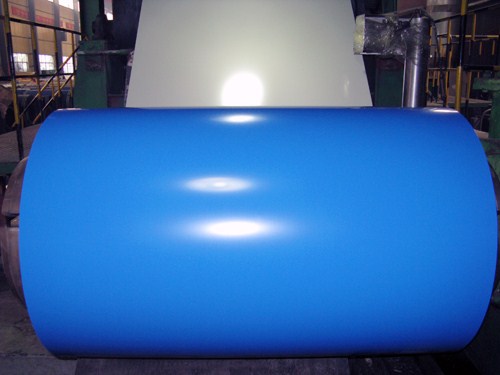

Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Prime PPGI Coils, ASTM A 653 CS type B, Z120 suitable for

corrugated metal roofs. Coil weight: 5 MT max.

Top: 5 microns primer + 20 microns RMP

Back: 7 microns mill's standard grey primer coat RAL 7035

Size: 0.50mm TCT x 1200mm x CColor: RAL 9002.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are used in the production of oil and gas machinery to create various components, such as pipelines, storage tanks, pressure vessels, and drilling equipment. The coils are typically shaped and welded to form these structures, which provide the necessary strength and durability required for the demanding conditions of the oil and gas industry.

- Q: What are the challenges in coil recoiling?

- Coil recoiling, which is also known as coil winding, brings about a range of challenges that depend on the specific application and requirements. Some of the common hurdles encountered in coil recoiling are as follows: 1. Precision and accuracy: Achieving precise and accurate winding is vital for optimal coil performance. It is crucial to maintain consistent tension throughout the winding process, ensure proper alignment, and control the speed in order to prevent variations in the electrical properties of the coil. 2. Wire management: Managing the wire during the recoiling process can be difficult. The wire may be fragile, prone to tangling, or have specific handling requirements, such as being sensitive to magnetic or thermal influences. Employing proper wire management techniques, such as tension control, wire guide systems, and spooling mechanisms, is necessary to prevent wire damage and ensure uniform winding. 3. Space limitations: In many cases, coils need to fit within specific space constraints. Designing and winding coils to fit compact spaces can be challenging, particularly when considering the required number of turns, wire size, insulation, and any additional components or structures that may need to be incorporated. 4. Material selection: The selection of the appropriate wire and insulation material is crucial for optimal coil performance and durability. Factors such as electrical conductivity, thermal properties, mechanical strength, and chemical resistance must be taken into account to ensure that the coil can withstand the operating conditions and environmental factors it will encounter. 5. Heat dissipation: Coils often generate heat during operation, especially in high-power applications. Efficient heat dissipation is crucial to prevent overheating and ensure the longevity of the coil. Techniques such as designing the coil with proper ventilation, utilizing cooling mechanisms, or incorporating heat sinks are employed to address this challenge. 6. Quality control: Ensuring consistent quality in coil recoiling can be challenging due to factors such as variations in wire properties, operator skill, equipment calibration, and environmental conditions. Robust quality control measures, such as conducting regular inspections, performing electrical tests, and monitoring process parameters, need to be implemented to maintain consistent coil performance. In summary, coil recoiling demands meticulous attention, precision, and adherence to specific requirements in order to overcome the challenges and produce high-quality coils that meet the desired performance criteria.

- Q: How are steel coils protected during shipping?

- Steel coils are protected during shipping through a variety of measures to ensure their safety and prevent damage. One common method is the use of steel coil cradles or saddles. These are specially designed structures that hold the coils securely in place and prevent them from shifting or rolling during transit. The cradles are typically made of sturdy steel or other durable materials and are specifically engineered to withstand the weight and pressure of the coils. In addition to the cradles, steel coils are often wrapped in protective materials such as plastic or paper. This wrapping acts as a barrier, shielding the coils from moisture, dust, and other potential contaminants that could affect their quality. The wrapping is typically applied tightly to the coils, ensuring that it stays in place throughout the shipping process. To further safeguard the coils, they are often loaded into shipping containers or onto flatbed trucks using specialized equipment. This equipment, such as coil hooks or lifting clamps, allows for safe and secure handling of the coils, minimizing the risk of accidents or damage during loading and unloading. In some cases, steel coils may also be packed into wooden or metal crates for added protection. These crates provide an extra layer of security and help to prevent any potential impacts or rough handling from causing damage to the coils. Overall, the protection of steel coils during shipping is of utmost importance to ensure that they arrive at their destination in optimal condition. By utilizing cradles, protective wrapping, specialized equipment, and additional packaging when necessary, the risk of damage is significantly reduced, allowing for a smooth and successful transportation process.

- Q: Can steel coils be coated with scratch-resistant materials?

- Yes, steel coils can be coated with scratch-resistant materials. These materials are designed to provide an additional layer of protection to the steel surface, minimizing the risk of scratches or damage during handling, transportation, or storage.

- Q: What is the accuracy of steel tape inspection?

- The project is through the detection of steel tape, steel tape each batch have the error him different, so do projects each into a batch of steel tape has to go through the inspection department, let this batch of steel tape has reached the same error range. All the measuring tools in this project are unified into these steel tape measures, so that the measurement error is guaranteed.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various products. The coils are typically processed and transformed into different shapes, such as sheets, strips, or wires, which are then used to create a wide range of items like appliances, furniture, automotive components, and construction materials. The durability and strength of steel make it an ideal choice for consumer goods, ensuring long-lasting and reliable products for consumers.

- Q: What are the common coil widths available for steel coils?

- The common coil widths available for steel coils typically range from 24 inches to 72 inches, with 36 inches and 48 inches being the most common options.

- Q: is there a type of steel that is stronger or does the rail represent the top of the line?

- consumer-friendly steel is used however the rails are tempered to cause them to stand up to the pounding they get from the practice wheels,the intense velocity trains utilized in Europe are made up of a greater variety of steel in accordance to organization who makes them in Germany ,i think of it replaced into Krupp's of Germany who cause them to

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords