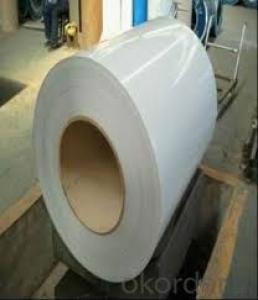

Pre-Painted Color Coated Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

PPGI and PPGL

0.14-3.0mm Special Color Galvanized / galvalume Steel Coil

1. Techinical standard: EN10169

2. Grade: TDX51D, SGCC

3. Thickness: 0.14-3.0mm (the most advantage thickness)

4. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250)

5. Base metal: Galvanized / galvalume steel

6. Finish Painting: 15-20miu PE on top

Back painting: 5-8miu PE on back

7. Type of PPGI and PPGL with pattern

Specifications:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.14-3.0mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-275g or AZ 40-150g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

Why Us:

1, Mill/factory supply, Quality protection, 4 Galvanized steel lines keep runing.

2, Competitive price with best quality and service

3, Nearest sea port, Convenient transportation, Efficient service team online for 24 hours

4, More than 7 years Export Experiences, More than 50 countries customers

5. Delivery time: Within 25-35 days after the receipt of L/C or according to customer's requirement.

Warranty:

As the professional manufacturer and supplier of the steel, CNBM steel corporation makes the steel co-operation mutual beneficial without any risky to the worldwide customers. CNBM Steel sales&service department not only promise to provide the high quality products, excellent communication, fast and reliable deliveries, as well as the reasonble price, but also help the customers to develop the market better with more efforts.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

CNBM Steel has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc...

commodityColor-coated Roofing Galvanized Steel sheet

Techinical Standard: JIS G3302-1998, EN10142/10137, EN 10169

gradeSGCC, DX51D / DX52D / S250, 280GD

Types: For general / drawing use

Thickness0.14-3.0mm

Zinc Coating: 40g-275g or AZ 40-150g

Spanglet:No/ small/ big regular

Surface treament:Chromed passivation, anti-finger print, skinpassed

Sheet weight:3-5MT

Profile model: YX14-65-825/ YX18-76.2-836 / YX14-63.5-825 /

YX35-125-750 / YX15-225-900 / YX10-125-875 /

YX12-110-880 / YX25-210-840 / YX25-205-820(1025)

Package: Properly packed for ocean freight exportation in 20' ' containers

Application:Roof, walls, internal and external decorating materials, building etc

Price termsFOB, CFR, CIF

Payment terms20%TT in advance+80% TT or irrevocable 80%L/C at sight

delivery time25 days after recepit of 20% TT

RemarksInsurance is all risks

MTC 3.1 will be handed on with shipping documents

We accept SGS certificatation test

Contact Information, Samson, TEL:86-021-51683864 FAX: 86-021-51683454

Phone: 0086-13671603878

commodity | Brick pattern Color Galvanized Steel Sheet (PPGI/ PPGL) |

Techinical Standard: | JIS G3312-1998, EN101169, ASTM A755 |

grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

Types: | For general / drawing use |

Base metal | galvanized, galvalume |

Thickness | 0.14-3.0mm(0.16-0.8mm is the most advantage thickness) |

Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

Type of coating: | PE, SMP, PVDF |

Zinc coating | Z60-275g/m2 or AZ40-150g/m2 |

Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

Back painting: | 5-7 mic. EP |

Color: | According to RAL standard |

ID coil | 508mm / 610mm |

Coil weight: | 4--8MT |

Package: | Properly packed for ocean freight exportation in 20' ' containers |

Application: | Industrial panels, roofing and siding for painting / automobile |

Price terms | FOB, CFR, CIF |

Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

delivery time | 25 days after recepit of 20% TT |

Remarks | Insurance is all risks |

MTC 3.1 will be handed on with shipping documents | |

We accept SGS certificatation test |

- Q: What are the different methods of transporting steel coils?

- There are several methods of transporting steel coils, depending on factors such as the weight, size, and distance of the shipment. Some of the different methods include: 1. Flatbed trucks: Steel coils can be transported on flatbed trucks, which have a large open platform for easy loading and unloading. This method is commonly used for short to medium distance shipments and allows for easy access to the coils. 2. Rail transport: Steel coils can also be transported via rail. Specialized railcars called coil cars are used for this purpose, which have a curved interior to securely hold the coils in place. Rail transport is often used for long-distance shipments, as it is cost-effective and can handle large quantities of steel coils. 3. Shipping containers: Steel coils can be loaded into shipping containers for transportation via sea or inland waterways. The coils are usually secured inside the container using bracing or blocking materials to prevent movement during transit. This method is commonly used for international shipments and allows for easy handling and transfer between different modes of transportation. 4. Barges: In certain cases, steel coils can be transported on barges along rivers, canals, or other inland waterways. Barges are often used for large and heavy shipments, as they offer a cost-effective and efficient mode of transportation. 5. Roll-on/roll-off (RoRo) vessels: RoRo vessels are specialized ships designed to transport vehicles and large cargo that can be rolled on and off the ship. Steel coils can be loaded onto trailers or flatbeds and driven onto the vessel, making it a convenient method for transportation. 6. Air freight: While not as common due to cost considerations, steel coils can also be transported by air. This method is typically used for urgent and time-sensitive shipments, or when the distance is too great for other modes of transportation. Air freight offers the advantage of speed and can be a viable option for certain situations. Overall, the choice of transportation method for steel coils depends on various factors such as cost, distance, time frame, and logistical requirements. Freight forwarders and logistics providers can help determine the most suitable method for a specific shipment.

- Q: Are steel coils affected by magnetic fields?

- Yes, steel coils can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized or attracted to magnets. When a magnetic field is applied to a steel coil, it can induce a magnetic field within the coil, causing the coil to become magnetized. This can have several effects depending on the strength and duration of the magnetic field. If the magnetic field is strong and the coil is exposed to it for a significant amount of time, it can cause the steel coil to retain some magnetism even after the magnetic field is removed. This can be problematic in certain applications where a non-magnetic material is required, as the magnetized steel coil may attract or interfere with other nearby objects. On the other hand, if the magnetic field is rapidly changing or fluctuating, it can induce electrical currents within the steel coil through electromagnetic induction. These induced currents, known as eddy currents, can generate heat within the coil, leading to energy losses and potential damage to the coil. Therefore, it is important to consider the effects of magnetic fields on steel coils in various applications. Protective measures such as shielding or demagnetizing processes may be necessary to minimize the impact of magnetic fields on steel coils when required.

- Q: What are the different coil packaging methods used for steel coils?

- There are several different coil packaging methods used for steel coils. These include wrapping the coils with stretch film or shrink wrap, using steel or wooden strapping to secure the coils, placing the coils inside wooden crates or metal frames, or using specialized coil packaging machines that can automatically wrap and secure the coils. Each method has its advantages and is chosen based on factors such as the size and weight of the coils, transportation requirements, and protection needed during storage or shipping.

- Q: What are the different methods of surface treatment for steel coils?

- There are several different methods of surface treatment for steel coils, each with its own benefits and applications. Some of the most common methods include: 1. Hot-dip galvanizing: This is a process where the steel coil is immersed in a bath of molten zinc, which forms a protective coating on the surface. Hot-dip galvanizing provides excellent corrosion resistance and is commonly used in outdoor applications such as roofing, fencing, and automotive parts. 2. Electro-galvanizing: In this method, a thin layer of zinc is electroplated onto the surface of the steel coil. Electro-galvanizing offers similar corrosion resistance as hot-dip galvanizing, but with a thinner coating. It is often used in applications where a smooth and aesthetically pleasing finish is desired, such as appliances, electrical equipment, and automotive components. 3. Powder coating: Powder coating involves applying a dry powder to the surface of the steel coil, which is then cured under heat to form a durable and protective layer. This method provides excellent resistance to chipping, scratching, and fading, making it suitable for a wide range of indoor and outdoor applications. 4. Painting: Steel coils can also be treated with conventional liquid paint coatings, which provide both protection and aesthetic appeal. Paint coatings can be customized to meet specific requirements such as corrosion resistance, UV protection, or chemical resistance. They are commonly used in industries such as construction, automotive, and appliances. 5. Pickling and oiling: This method involves removing any scale or rust from the surface of the steel coil by dipping it in an acid solution (pickling), followed by a coating of oil to prevent reoxidation. Pickling and oiling are typically used for temporary corrosion protection during storage and transportation of steel coils. 6. Pre-painted coatings: Steel coils can be coated with pre-painted finishes at the manufacturing stage. Pre-painted coatings are applied in a continuous process, where the steel coil is passed through a coating line, and a layer of paint is applied. This method provides a wide range of colors and finishes, making it popular in the construction, automotive, and appliance industries. These are just a few of the methods commonly used for surface treatment of steel coils. The choice of method depends on factors such as the desired level of corrosion resistance, aesthetics, environmental conditions, and the specific application requirements.

- Q: What is future prospect of these steel structures, are they really weather proof like everyone believes??

- Solid Steel Buildings, Inc. is an all encompassing Steel Building Solution provider.? Our methodology will provide you with a low cost steel building with the highest possible quality.

- Q: How are steel coils shaped into specific forms?

- Steel coils are shaped into specific forms through a process called cold rolling, where the coils are passed through a series of rollers that apply pressure to gradually shape and form the steel into the desired shape.

- Q: I have heard of Cold Rolled steel, Castle Forged steel and Valerian steel and i was just wondering the difference between them.I know Valerian steel is by far the strongest and durable but what about the other two types? Do you know because i haven't read all the books yet.

- Cold rolled steel is referring to rolled steel. It is referring to weapons made from rolled steel that is unrolled and stamped out. In real-life, rolled steel isn't nearly as strong as steel that is cast and forged. Think of a cheap dinner fork that you can easily bend and a nice dinner fork you can't bend at all. The cheap fork is stamp-pressed out of rolled steel and the nice fork is cast. In Game of Thrones, cold rolled steel is crap, but it's cheep and common. Castle forged steel is the best most people have available, much higher quality than cold rolled steel. Presumably it's forged in the castles of Westeros, including King's Landing. Valerian steel is special, rare steel that was anciently forged that is stronger than any other steel. They no longer make Valerian steel since the fall of Valeria. As such, the only Valerian steel available is by getting it from things already made. In real-life, it might be comparable to the extremely high quality steels forged into ancient katanas, ninja fighting swords from Japan. The Lanisters took a sword made of Valerian steel that had been passed down to Ned Stark and had it melted down, recast, then forged into two smaller swords.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- The issue is heat conduction. Copper trasferrs heat rapidly and therefore ensures uniform heat around the base or sides of teh pot. The thick walls can be two different purposes. Sometimes the steel is made in layers for the purpose of providing insulation. If a pot insulates heat then the heat will transfer in a steady manner and the need for constant fuel heat is reduced. Thus, if I want to simmer and can store some of the heat in the pot itself then I know it will transfer slowly because it has to go through the layers first. Secondly, the layers will transfer heat between them allowing for uniform heating and this avoids hot spots. Wash you pots with an acid. Lemon will clean copper very nicely. If you have to scrub then heat gently and use salt or baking soda as an abrasive. With a tea kettle you do not care about heat conduction past the point of the boil. when the boil arrives the job is done.

- Q: How are steel coils used in the production of steel plates?

- The production of steel plates heavily relies on steel coils, which play a crucial role. These coils serve as the primary raw material and are vital in the manufacturing process. The initial step involves creating steel coils by heating and cooling molten steel to form thin, flat strips. These strips are then further processed in a rolling mill, where they undergo a series of rollers to decrease their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are uncoiled and straightened. This involves passing them through a machine to eliminate any curvature or deformities, ensuring that the strips are completely flat. Subsequently, the straightened coils are cut into specific lengths to match the required dimensions of the steel plates. After being cut, the coils undergo another significant step called leveling. This step involves passing the strips through a leveling machine to remove any residual stress or warping that may have occurred during the production process. Leveling guarantees that the steel plates possess a consistent thickness and are free from any distortions, making them suitable for various applications. When the leveling process is completed, the steel coils are finally transformed into steel plates. These plates can be further processed according to the desired end-use. They may undergo additional treatments like heat treatment, surface finishing, or coating to enhance their strength, durability, and resistance to corrosion. To summarize, steel coils serve as the starting point in the production of steel plates. They undergo several essential steps, including rolling, uncoiling, straightening, cutting, and leveling, to convert them into flat and uniform steel plates. These plates can then be further processed and tailored for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: I want to make a stock removal knife, but I am really confused about what steel to use. I am just a beginner but I read o1 steel is great? Also I am kind of on a budget.

- 01 tool steel is easier to work with. You need to contact places like Pop Knives and Supplies out of Washington, Georgia or Sheffield Steel out of Florida, I made custom knives for years with my husband. Made alot with ATS-34 Stainless. Look at links on my website source.

Send your message to us

Pre-Painted Color Coated Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords