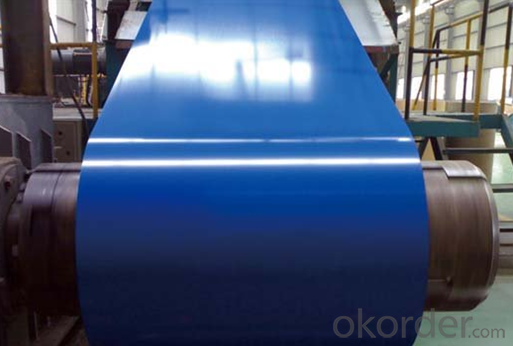

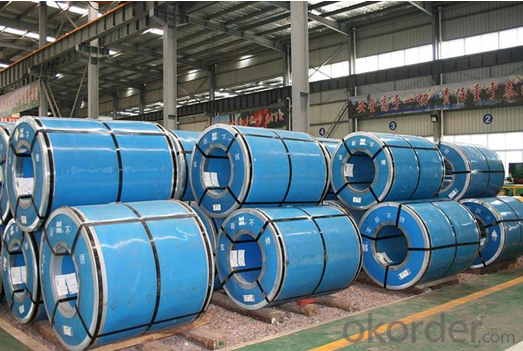

Pre-Painted Steel Coil for Building/Color Coated Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1) Standard: JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

2) Grade:DX51D+Z

3) Thickness: 0.12mm-0.6mm, all available

4) Width: 600mm-1250mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Hardness:Soft,full hard

8) Zinc Coating: 50-150g

9) Paint coating: Top 15-20mirco ,back 7mirco

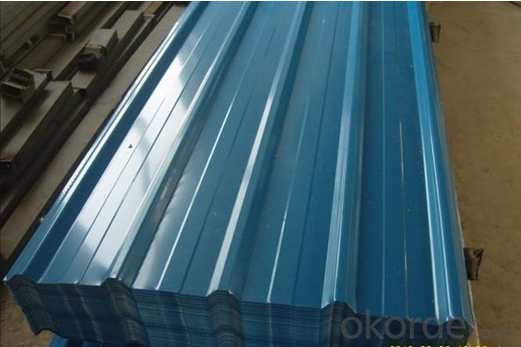

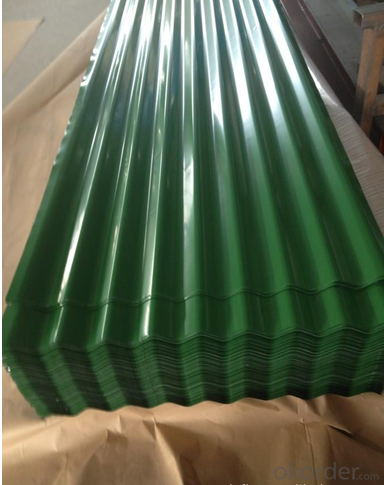

10) Color series: Sea blue,white grey and all RAL color

PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Which steels were origianally designed to be used to cut and shape metals and other materials?- alloy steel- high carbon steel- carbide steel- tool steelthanks

- Tool steels These were designed to be used as hardenable, dimensionally stable materials for cutting of metals. The alloying elements they contain (including tungsten, vanadium, niobium and molybdenum as well as chromium)are there to produce carbides (mainly) which are stable at dull-red heat. This cannot be achieved with high carbon steels, carbide steels or (normal) alloy steels which all lose their strength and hardness at metal cutting temperatures.

- Q: I am buying my boyfriend a steel guitar for our one year anniversary and I was curious what brand or company I should look into. I want something high quality yet traditional. Money is not really an issue but I don't exactly want to spend an arm and a leg either.Thank you in advance!

- The term steel guitar usually refers to pedal steel guitar or lap steel guitar. I suspect that you really meant to ask about a steel stringed guitar for your boyfriend. Steel guitars are played with a slide and are usually electrified. A pedal steel guitar site on legs and a lot of the chord changes are made with knee levers or foot pedals. If that's what your boyfriend is looking for, expect to spend a couple of thousand dollars. Look for brands like Emmons, Carter, Sho-Bud, or Fessenden. Carter Starters have been discontinued, but you might find one for under a thousand.

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they are rolled and formed into the required shapes and sizes to create the structural components of the towers. The coils are processed and cut into specific lengths, which are then welded or bolted together to construct the tower sections. The robustness and strength of steel make it an ideal material for transmitting large amounts of electricity over long distances, ensuring the stability and reliability of power transmission towers.

- Q: What are the dimensions of steel coils used in the construction materials industry?

- The dimensions of steel coils utilized in the construction materials industry may differ based on specific requirements and applications. Nevertheless, there exist some commonly employed dimensions. In this industry, steel coils usually possess a width that spans from 600mm to 2,000mm, with the most frequently observed widths being 1,000mm and 1,200mm. The thickness of these coils can fluctuate between 0.4mm and 2.5mm, with the most commonly adopted thicknesses ranging between 0.6mm and 1.2mm. The inner diameter of the coil, commonly referred to as the core size, can vary from 508mm to 610mm, with 610mm being the predominant core size. Moreover, the weight of these coils can also differ, with typical weights ranging from 3 to 15 tons. It is important to emphasize that these dimensions might alter depending on specific project requirements and can be tailored to suit the demands of a particular construction project.

- Q: Can steel coils be coated with nickel?

- Yes, steel coils can be coated with nickel.

- Q: Can steel coils be coated with vibration-damping materials?

- Yes, steel coils can be coated with vibration-damping materials.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Combat steel? No such thing... Combat steel is a commercial product... not a true type of steel, since there is no ASTM grade of combat steel... And carbon steel is a WHOLE list of different types of steel, whether it's tempered or not... The company does not provide what steel specifications it has other than combat steel... So my best guess is that it's an alloy of 1095 or 301 spring tempered... both are resilient to snapping and fatigue, and common in modern swords... however, they do not hold an edge very well and are prone to rusting...

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems as they serve as the primary heat transfer component. The coils are designed to efficiently transfer heat between the air and refrigerant, allowing for effective cooling or heating of the space.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- Damascus steel is the poorest quality. The laminations separate under stress. Centuries ago the only way to get steel bars was to make it up by hammering wires together in a series of welds. The welds usually were porous and the steel would fail. The pattern of the welds is attractive to some people. An old file has good hard steel and wiill make up into a knife if it is annealed to make it easier to shape and cut. The hardness can be restored by tempering. Treating with oil is the cure to prevent rust.

- Q: What is the current value of steel? Is it expected to increase in value?

- They'd never be worth much for their steel content, likely always less than face value. They might be worth a premium as coins, but not anything you'd call an investment.

Send your message to us

Pre-Painted Steel Coil for Building/Color Coated Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords