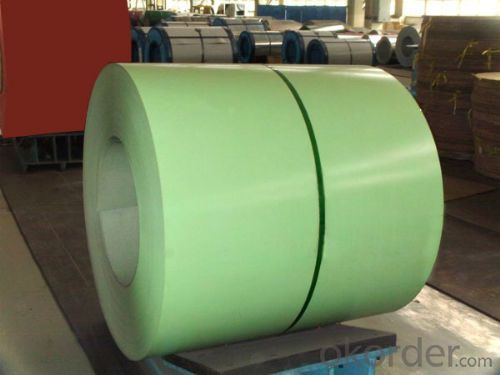

Prepainted gavanized steel coil and sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | SGCC, SPCC, DC51D, SGHC,A653 | Thickness: | 0.16mm-0.6mm |

| Place of Origin: | Brand Name: | Model Number: | 0.16mm-0.6mm *1250mm or under | ||

| Type: | Steel Coil,Prepainted Steel Coil/sheet | Technique: | Cold Rolled | Surface Treatment: | Coated,coating |

| Application: | Building construction,warehouse,airport,etc | Special Use: | High-strength Steel Plate | Width: | 1250mm or under |

| Length: | customized | Color: | Multicolor | Color Steel Coil/Sheet: | Ppgi/Color Coated Steel Plates |

| Trustworthy supplier: | Prepainted Steel Coil/sheet | color steel sheet: | top quality | price: | competitive |

Packaging & Delivery

| Packaging Detail: | seaworthy expot package |

| Delivery Detail: | on request |

Specifications

1.10 year's experience

2. advanced coating equipment

3.competitive price

4.soonest delivery

5.various color

Colorful ppgi prepainted galvanized steel coil

Hi ! Welcome To Our Company

High quality products , Sincere service for you

PPGI 0.16-0.6mm 700-1250mm various color/

10 year's experience /SGS

Product Description :

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001.ISO14001.OHSAS18001 |

| Thickness | 0.16mm-0.7mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | customized |

| Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

Our advantage :

1. Expertise:

10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We produce resin and paint by ourself, which greatly reduce our cost!

3. Accuracy:

We have a technician team of 40 people and a QC team of 30 poeple, ensure our products is exactly what you want.

4. Materials:

All color Steel Sheets are made of high-quality raw materials.

5.Certificate:

Our products are certified by TUV, ISO9001:2008,ISO14001:2004 etc.

6. Productivity:

We have three large-scale production line, to guarantee all your orders will be finished in earlist time

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- glass what

- Q: What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- Neuropathy Solution can help people of neuropathy to eliminate all the outward indications of this problem including : tingling, prickling feeling , numbness of the area round the affected nerves, quick problems , sharp as well as using feeling in the nerves. Dr. Randall Labrum, the author of this unique guide feels that you will eliminate most of the outward indications of neuropathy and eliminate that dangerous illness permanently.

- Q: What are the dimensions of steel coils used in automotive accessory manufacturing?

- The dimensions of steel coils used in automotive accessory manufacturing can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in this industry range from 0.3 mm to 4.0 mm in thickness and from 600 mm to 2000 mm in width. The length of the coil can also vary, but it is commonly around 2000 meters.

- Q: How do steel coils contribute to the automotive manufacturing sector?

- Steel coils are essential in the automotive manufacturing sector as they are used to produce various components such as body parts, frames, and suspension systems. The high strength and durability of steel coils make them ideal for ensuring the safety and structural integrity of vehicles. Additionally, steel coils are easily moldable, allowing manufacturers to create complex shapes and designs, contributing to the overall aesthetics and functionality of automobiles.

- Q: How are steel coils used in the production of automotive exhaust systems?

- Steel coils are typically used in the production of automotive exhaust systems as they provide the necessary material for manufacturing exhaust pipes and components. The coils are often processed and shaped into the desired forms, such as tubes or mufflers, and then welded or fastened together to create the exhaust system. Steel coils are favored due to their durability, heat resistance, and ability to withstand the harsh conditions of exhaust gases, ensuring the longevity and efficiency of the automotive exhaust system.

- Q: How are steel coils used in the production of steel washers?

- Steel coils are used in the production of steel washers by being uncoiled and fed into a stamping machine. The machine then cuts and shapes the steel into individual washer blanks. These blanks are then further processed and finished to create the final steel washers.

- Q: Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Fluffy blue handcuffs.

- Q: What are the different types of steel coil slitting machines?

- There are several types of steel coil slitting machines, including rotary slitters, loop slitters, and stationary slitters. Rotary slitters use rotating circular blades to cut the coils into desired widths, loop slitters use a looping process to cut the coils, and stationary slitters use stationary blades to slit the coils. Each type of machine has its own advantages and is suitable for different applications.

- Q: Explain your answers please. I was watching mythbusters and they bought a steel coffin over a wooden one because they thought it would hold more dirt. Now how come bridges that have been made of wood lasted way longer than steel bridges? Or rollercoasts for example.

- steel bridges that have been made of wood lasted way longer than steel bridges NOT true. Why do you think bridges are made from steel or concrete, and not wood? wood rots and splinters and doesn't last more than 10 years when exposed to the weather. .

- Q: How are steel coils used in the automotive stamping process?

- Steel coils are a critical component in the automotive stamping process. These coils are essentially large rolls of steel that are unwound and fed into stamping machines. The coils are typically made of high-quality steel and come in various thicknesses and widths to meet the specific requirements of different automotive parts. During the stamping process, the steel coils are fed through a series of dies and presses that shape and form the metal into the desired automotive components. The coils are unwound and passed through a straightener to remove any bends or twists, ensuring a smooth and consistent feed into the stamping machine. The stamping machine then uses a combination of hydraulic or mechanical force to press the steel coil against a die, which is a specially designed mold that gives shape to the metal. The die is often made of hardened steel to withstand the pressure and provide accurate and repeatable results. The steel coil is fed into the stamping machine at a high speed, and as it passes through the die, the metal is formed into various automotive parts such as body panels, doors, hoods, fenders, and other structural components. The stamping process allows for high precision and consistency in producing these parts, ensuring they meet the required specifications and tolerances. Once the metal is formed, it may undergo additional processes such as trimming, piercing, or bending to achieve the final shape. These processes are often performed in subsequent stamping stations or by using progressive dies that combine multiple operations into a single pass. Overall, steel coils play a vital role in the automotive stamping process as they provide the raw material required to produce various components. The use of steel ensures the necessary strength, durability, and safety of the automotive parts while maintaining cost-effectiveness and mass production capabilities.

Send your message to us

Prepainted gavanized steel coil and sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords