Better Quality Pre-Painted Galvanized/Aluzinc Steel Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

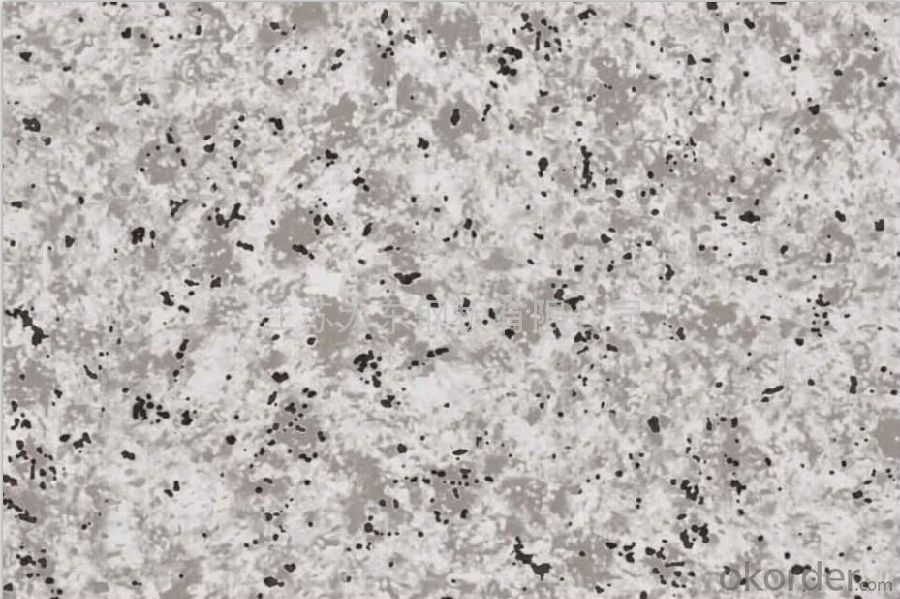

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners by being uncoiled and then shaped into various forms such as screws, nuts, bolts, and washers. The coils provide a continuous and efficient supply of high-quality steel material, ensuring consistent and reliable production of fasteners.

- Q: How do steel coils compare to other materials in terms of cost?

- Compared to other materials, steel coils offer greater cost-effectiveness. This is due to the fact that steel is widely accessible and abundant, leading to relatively low production costs. Moreover, steel coils boast an extended lifespan and require minimal upkeep, resulting in reduced expenses over time. The exceptional durability and strength of steel also make it an optimal selection for a wide range of applications, further augmenting its cost-effectiveness. When contrasted with materials such as aluminum or copper, steel coils are typically more economical, making them the preferred option for numerous industries.

- Q: hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Primary Steel Making first Iron ore Coke Lime stone are mined and then took to the steel plant and put in the top off a blast furnace and sinks down to the bottom off the blast furnace and turns into molten iron. Once this process has been done it is then transferred to a BOS (Basic Oxygen Steel Making) this is then poured from a ladle into the BOS and a Lance is inserted into the BOS and pure oxygen is blown into the BOS for about 30 min and turns into steel.

- Q: Is Ace Steel's wrestling school still running?And do you know if their are any other wrestling schools in chicago?

- Steel Domain

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- Steel making today is a faster process as use Blast furnace which Coke Limestone Iron ore are fed into the top of the furnace. after these are fed in a exothermic happens and converts these ores into Iron. Iron is not strong enough to be used in thing this is formally known as pig iron. To convert Iron ore into steel it has to go to a process called the BOS Basic Oxygen Steel-making were oxygen is blown onto the iron ore for about 30 to 45 min and this then turns it into steel as all the impurities are taken out and this floats on top and known as slag and used for things such as road building. Once you have steel this is then pored into ladles and taken to the continuous caster and rolled into slabs, billets and bars and then cut off and rolled into a finished products and then taken to compniaes to be made into thins you see made out off metal such as skyscrapers. Hope this helps :o)

- Q: explain what happen if carbon steel is exposed to an oxygen rich atmosphere at elevated temperature inside a furnace.

- Blowing oxygen or air rich in oxygen through molten carbon steel is a way of lowering the carbon content. The properties of carbon steel depend very much on the carbon content . too much and it is very brittle. It is all governed by a complex phase diagram. If the steel isn't actually melted, then only insignificant effects at the surface will occur.

- Q: Can someone help me...i have a diagram and were supposed to calculate the steel tonnage needed for the pictre. Can someone tell me step by step what i need to do (ex:find area of ...)

- Find the volume of steel and then multiply that by the density of the steel.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: Can steel coils be used in the production of packaging materials?

- Yes, steel coils can be used in the production of packaging materials. Steel coils are commonly used to manufacture metal packaging materials such as cans, containers, and drums. The strength and durability of steel make it an excellent choice for packaging materials that require protection and stability. Additionally, steel coils can be easily shaped and formed to meet specific packaging requirements, making them versatile for various applications in the packaging industry.

- Q: I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- Steel is more dangerous, both in a fatal metal whip way and a metal splinters in my hand way. Steel weighs more. So why would anyone continue to use steel? Cost and care. Care: Steel can sit for years without having to worry about dry rot (as long as it's not out in too horrible of weather conditions). Steel is much more resistant to fraying. You don't have to baby steel so much to keep it in good conditions. Cost: As of right now, steel is less than half the cost of synthetic. A synthetic rope can cost as much as many electric winches which include a steel cable. I find that I don't use my winch nearly enough to warrent the extra care or cost of a synthetic. The weight savings would be nice, but I kind of ruined that a long time ago with the winch bumper, rock sliders, plate steel fenders/flares, belly armor and frame plating.

Send your message to us

Better Quality Pre-Painted Galvanized/Aluzinc Steel Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords