Prepainted Galvanized Steel Coil Z275 PPGI Galvanized Steel in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Bried Introduction:

1).Colr steel is coated with organic layer, which provides higher anti-corrosion property and longer lifespan than that of galvanized steel sheets.

2).The base metals for color steel consist of cold rooled. HDG lectro-galvanized and hot-dip alu-zinc coated steel. The finish coats for color tels can be classified into groups as follows: polyester, silicon modiied polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3).The production process has evolved from one-coating-and-oe-baking to double-coating-and-double-baking, and even three-coatig-and-three-baking.

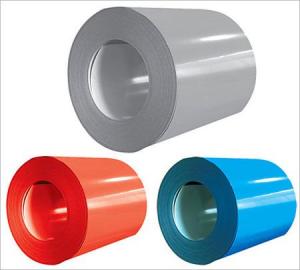

4).The color of the color steel has a very wide selection, like orange, creamcolored, dark sky blue, sea blue, bright red, ivory white, procelain blue, etc.

5).The color teels can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

2. Steel coil, prepainted steel coil,prepainted galvanized steel coil Advantages:

(1).High strength, Good corrosion

(2).Well rainproof performance

(3). Easy to install and remove

(4).Competitive price with best quality

3.Image of prepainted steel coil:

4.Data of prepainted steel coil:

Thickness | 0.14mm-1.2mm |

Width | 600mm-1250mm |

Single weight | Max 6.0MT |

Zinc thickness | 30-275g/m2 |

Steel gardes | TDC51D2,TDC51D+AZ,TDC51D, GR.A, GR. B, SPCC, SPHC, DX51D, ect. |

Standard | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,, BS, ect. |

Packing | Wrapped by plastic film and waterproof paper, and then fastened on wooden pallet.Or as you request. |

Used | Used in building material, roof, profile,pipe making, furniture making, etc. |

Minimum quantity | Can be 25MT |

Price | FOB Tianjin Port or Qingdao Port 600-950USD/MT |

Delivery time | within 25 days after receiving 30% deposit or copy of LC at sight |

Payment terms | T/T or L/C |

Supply ability | 10,000 MT per month |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the role of steel coils in HVAC systems?

- Steel coils play a crucial role in HVAC (heating, ventilation, and air conditioning) systems as they are responsible for facilitating the transfer of heat between the air and the refrigerant. In HVAC systems, steel coils are typically used in two main components: the condenser coil and the evaporator coil. The condenser coil is located in the outdoor unit of an HVAC system and its primary function is to release the heat from the refrigerant into the surrounding air. This coil is made up of multiple steel tubes that are bent into a serpentine shape and are attached to aluminum fins. As the hot refrigerant flows through these tubes, the steel coils ensure maximum surface area contact with the surrounding air, allowing for efficient heat transfer. Through this process, the heat is dissipated into the outdoor environment, resulting in the cooling of the refrigerant. On the other hand, the evaporator coil is situated in the indoor unit of the HVAC system and its role is to absorb heat from the air inside the building. Similar to the condenser coil, the evaporator coil consists of steel tubes that are connected to aluminum fins. The refrigerant, in a cold state, flows through these tubes, and as warm air from the building passes over the coils, the heat is transferred from the air to the refrigerant. This heat absorption process cools down the air, which is then circulated back into the building, providing the desired cooling effect. Overall, steel coils in HVAC systems are essential for heat transfer between the air and the refrigerant. Their design and placement allow for efficient cooling or heating of the air, depending on the system's mode of operation. Without steel coils, HVAC systems would not be able to effectively regulate the temperature and provide the desired comfort levels in residential, commercial, and industrial buildings.

- Q: What are the common methods of joining steel coils together?

- The common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), and adhesive bonding.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- Right now, steel is worth $150/ton. Who purchase it? Well, not every scrap yard handle steel, you have to call them up, or look at the company name that has the word steel or iron. But price can vary from each scrap yard. Try to call around. As for someone to pick it up, the scrap yard will mostly charge you a trucking fee and then the price for steel would be lower. But here is another bad thing if you have it pick up. I know some scrap yard are bad...reall bad..they will skim off some weight...a 1k lbs to 2k lbs. Wish you good luck!

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are an essential component in the production of power generation equipment due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are widely used in various applications within the energy sector. One of the primary uses of steel coils in power generation equipment is in the construction of generators. Steel coils are used to create the stator and rotor cores, which are crucial parts of the generator. These cores are responsible for generating the magnetic field necessary for converting mechanical energy into electrical energy. The steel coils provide the necessary support and stability to ensure efficient and reliable power generation. Additionally, steel coils are used in the manufacturing of transformers, which play a critical role in power distribution. Transformers are responsible for stepping up or stepping down the voltage levels to facilitate the transmission of electricity over long distances. Steel coils are used to create the primary and secondary windings of the transformer, enabling the efficient transfer of electrical energy. Another application of steel coils in power generation equipment is in the production of turbines. Turbines are used in various types of power plants, such as hydroelectric, thermal, and nuclear power plants, to convert the kinetic energy of a fluid or steam into mechanical energy. Steel coils are used in the construction of turbine casings, blades, and other components, ensuring the necessary strength and reliability to withstand high temperatures and pressures. Furthermore, steel coils are used in the production of boilers, which are crucial in thermal power plants. Boilers are responsible for converting water into steam, which is then used to drive a turbine. Steel coils are used in the fabrication of boiler tubes, where the steam is generated, due to their excellent heat resistance and strength. In summary, steel coils are an integral part of the production of power generation equipment. They are used in the construction of generators, transformers, turbines, and boilers, providing the necessary strength, durability, and thermal resistance required for efficient and reliable power generation.

- Q: What are the different packaging options for steel coils?

- The different packaging options for steel coils include wooden pallets, steel cradles, eye-to-sky or eye-to-wall packaging, and steel banding or strapping. These options are used to ensure the safe transportation and storage of steel coils, preventing damage and maintaining their shape and quality.

- Q: haii, i have this guitar thats quite old and im not quite sure whether to put steel strings on it. there were very thin badly worn steel strings on it when i got it, so i think its an acoustic

- That's a very low-end Kay, maybe from the 60's or 70's. It has a weird mixture of steel-string and classical features that you often see in cheap imports from around that time, maybe because the factory didn't want to stock different parts for different lines. The tuners (one of which is missing) are made for steel strings. They will work with nylon but not well. The bridge is a generally classical type but appears to be bolted on and seems to have some compensation carved into the saddle, which indicates it may have been intended for steel strings. Probably it's ladder braced, which is not a great design for either type. It has a classical rosette and a steel-string pickguard. I am guessing the neck has steel reinforcement but unless there's a sticker there's no way to tell. Personally I'd put light or (preferably) extra-light steel strings on it. The short scale length will help keep the tension down. I'd keep an eye on the neck though. You could also try silk steel to be on the safe side, but the bass response will probably be lacking.

- Q: On a fixie frame what should i get an aluminum frame or a steel frame

- Aluminum Fixie

- Q: I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

- Q: What are the common welding defects in steel coils?

- There are several common welding defects that can occur in steel coils during the welding process. These defects include: 1. Porosity: This is characterized by small holes or voids in the weld metal, which are caused by gas entrapment during the welding process. It can weaken the weld and make it more susceptible to corrosion. 2. Lack of fusion or incomplete penetration: This defect occurs when there is inadequate fusion between the base metal and the weld metal, or when the weld metal does not fully penetrate the joint. It can result in a weak or brittle weld. 3. Cracks: Cracks can occur in the weld metal or in the heat-affected zone (HAZ) of the base metal. They can be caused by factors such as high stress levels, improper cooling, or inadequate preheating. Cracks can significantly reduce the strength and integrity of the weld. 4. Undercutting: Undercutting is a groove or depression that forms at the toe of the weld due to excessive melting of the base metal. It weakens the weld and can lead to stress concentration and potential failure. 5. Excessive spatter: Spatter refers to the small droplets of molten metal that are expelled from the welding arc and can land on the surface of the steel coil. Excessive spatter can result in a rough or uneven surface finish and may require additional cleaning or grinding. To minimize these welding defects in steel coils, it is important to ensure proper weld preparation, including cleaning and removing any contaminants from the surface of the steel. Additionally, using the correct welding parameters, such as appropriate heat input and travel speed, can help to minimize defects. Regular inspection and quality control measures can also help to identify and address any defects before they become more serious issues.

- Q: What is the current value of steel? Is it expected to increase in value?

- The steel in steel cents is the same as the steel in soup cans you throw out all the time. There is no sense in holding steel cents for their value as scrap. There are way too many steel cents around for them to ever have much numismatic value.

Send your message to us

Prepainted Galvanized Steel Coil Z275 PPGI Galvanized Steel in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords