Prepainted Galvanized Steel Coil/PPGI/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Steel Coil

Product Description

Color Coated Galvanized Steel Coil

ISO System

SGS and BV Audited company

Industry experience over 10 years

Management Systems-Internal Software

Finished Product Inventory-More Than 500 Tons

Raw Material inventory -Over 800 Mertic Tons

Shipment of goods -More than 30 countries worldwide

We have the most convenient transport and prompt delivery

We offer competitive price with best service

We have high technical production line with top quality products

We have win high reputation based on best quality products

Product Description

PPGI:

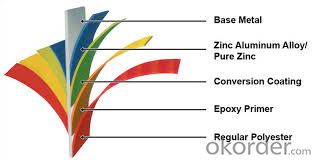

1, Introduction: Color coated steel coils(sheets), i. e. PPGI, also called prepainted steel coils(sheets), are made of galvanized steel coils(sheets) with polymer coatings as surface. It's a new enclosure material and building board with characteristics of light-weighted, heat preserved&insulated, easily installed with bright colors.

2, Production Process: Pretreatment(Degreasing)_Drying_Chromating_Paint Basic Oil_Cooling_Drying_Color Coating_Cooling_Film-covering_Rolling Up

3, Characteristics:

Good at corrosion resistence. Besides zinc coating of the basic plate of galvanized steel sheet, the color coating as the surface has double lifetime to ensure better anticorrosion effect.

with excellent cold bending molded manufacturablity, PPGI products can be processed or directly used as final product. As being light-weighted and conveniently transported, they're widly used to replace wood to save energy.

There're thousands of colors can be chosen as per different application. Any color plays well in decoration.

No pollution with high recycling rate, PPGI coils and sheets are strongly recommended as enviroment-friendly products by the government.

4, Appliance: Thanks to the above characteristics, color coated steel coils and sheets are widly used in construction, furniture industry, transportation industry, ect.

5, eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized.

Type of substrate | Grade of color plate | Standard | Application& feature |

Hot dip galvanized | TDC51D+Z | DC51D+Z | ordinary use |

TDC52D+Z | DC52D+Z | SPCD | |

TDC53D+Z | DC53D+Z | SPCE | |

TS280GD+Z | TS280GD+Z | Structure use | |

TS350GD+Z | TS350GD+Z | Structure use | |

TS550GD+Z | TS550GD+Z | High strength structure use | |

Hot dip galvalume | TDC51D+AZ | DC51D+AZ | ordinary use |

TDC52D+AZ | DC52D+AZ | SPCD | |

TS250GD+AZ | S250GD+AZ | Structure use | |

TS300GD+AZ | 300GD+AZ | Structure use | |

TS350GD+AZ | 350GD+AZ | Structure use | |

TS550GD+AZ | 550GD+AZ | High strength structure use |

Type of coating process | Front:double coated&double drying |

Type of substrate | Hot dip galvanized,galvalume,zinc alloy,cold rolled steel,aluminium |

Coating | Top paint:10-25 micron(Normal 10-12 micron) |

Back paint:5-12 micron(Normal 5-7 micron) | |

ID(mm) | 508/610mm |

Coil weight(ton) | 3-9 ton |

Coating types | Top paint:PVDF,HDP,SMP,PE,PU |

Functions: | Decorative,Machinability,Weather resistance,Scrath resistance,Stain |

Primer paint: | polyurethane,Epoxy,PE |

Back paint: | Epoxy,modified polyester |

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- Funny! 100!

- Q: How are steel coils protected during transportation?

- Steel coils are typically protected during transportation by being wrapped in layers of protective materials such as plastic or paper, and then secured onto pallets or placed inside specialized containers. This helps prevent damage from moisture, dust, and other external elements, ensuring the coils arrive at their destination in good condition. Additionally, proper handling and loading techniques are employed to minimize the risk of any physical damage during transportation.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: I'm just wondering what the best steel would be for an edc/hunting knife that could put up with alot of abuse.

- i have been a chef for 10 years now and have always had an obsesive composion with my knifes being dual. i hate it. after spending $100's of dollars on knifes i have found a couple of things to be key. where the knife comes from is important. japan and sweden are a notch above the rest. this just has to do with there tradition of fine craftmanship and pride in quality knife making that goes back 1000's of years. the thickness of the blade is important. the thinner the better. and the blade angel most knifes are around 20 degrees but less is better. it makes them easier to sharpen. and don't be fooled knifes need to be hoaned everyday of use the is no such thing as a forever sharp knife. at least not for a chef. so having said that. the best knifes on the market for quality and price are global, mizuno, mac, and the ones i use calphalon katana. investing in a good diamond steel is just as important i use fury fingers by ozzi tech. good luck i wish i had a girlfriend like you.

- Q: y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- the grade of the sword is one aspect but there's more to it. the quality of the sword itself is a much more important factor a good quality 1045 grade blade can often be much better than a medium quality 1060 or 1095 blade. the quality of the work is much more important than the grade of the steel

- Q: I beat fallout 3 and i downloaded broken steel expansion. I have no idea how to get to broken steel in other words i do not know how to start playing it.

- Broken Steel Fallout 3

- Q: What are the common problems encountered with steel coils during production?

- Some common problems encountered with steel coils during production include surface defects such as scratches, rust, and scale formation, dimensional deviations, coil breaks or tears, edge defects, and coil slippage. Other issues may include coil handling and storage problems, coil winding or coiling defects, and quality control problems such as inconsistent chemical composition or mechanical properties.

- Q: How do steel coils compare to other materials?

- There are multiple advantages to using steel coils instead of other materials. Firstly, steel is renowned for its strength and durability, which makes steel coils highly resistant to wear and tear. This quality allows them to be used in a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for high-temperature environments. Furthermore, steel coils offer superior corrosion resistance compared to many other materials. This is especially important in industries like construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another benefit of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. As a result, steel coils are suitable for a wide range of applications in manufacturing, construction, transportation, and energy industries. Moreover, steel coils provide good value for money. Despite their numerous benefits, steel coils are generally more affordable than materials like aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries seeking high-quality and reliable materials. In summary, steel coils offer multiple advantages over other materials. They possess high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and easily customizable for different applications. Additionally, they provide good value for money. Overall, steel coils are a dependable and efficient option for various industries and applications.

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are commonly used in the manufacturing of metal structures as they provide a convenient and efficient way to shape and form various components. These coils are unrolled and then processed through machinery that cuts, bends, and shapes the steel into the desired size and shape. This allows for precise and consistent fabrication, making it easier to assemble and construct metal structures such as buildings, bridges, and machinery.

- Q: When maintaining a japanese knife: Is a honing steel still necessary if I have a fine 3000/8000 grit whetstone?which do you prefer?

- A steel is to clean off an edge and remove any bends on the bevel, it is not directly for sharpening as it removes no material from the knife (or should not). A whetstone, however fine, does remove material. A steel to maintain an edge, a stone to restore an edge. They are different items for different purposes.

Send your message to us

Prepainted Galvanized Steel Coil/PPGI/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords