Prepainted Galvanized Color Coated PPGI Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

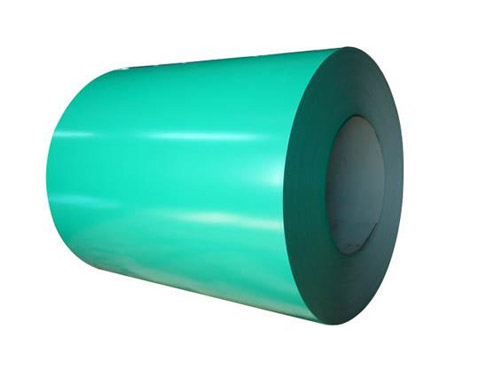

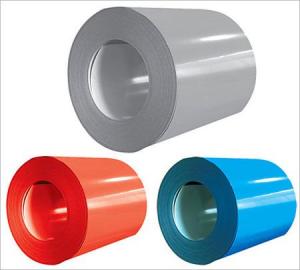

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

Thickness | 0.12-1.2mm |

Width: | 700-1250mm |

Material: | SGCC,SGCD,SECC,SECD,DX51D+Z |

Zinc coating: | 30-180G/M2 |

Surface Structure: | galvanized ,zero spangle, regular spangle or normal spangle |

COLOR: | RAL number or sample colour |

Coating: | Topside: 5micron primer +15-20microns polyester Backside: 5-8microns primer epoxy. Surface treatment: chromated and oiled, chromated and non-oiled |

5.FAQ of Prepainted Galvanized steel Coil

We have organized several common questions for our clients,may help you sincerely:

1) How do you control your quality?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

2) how long we will receive the goods?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,

and it takes around 28 days to reach your port of destination. But is up to different destination

3) what is your moq?

Normally our moq is 25per size ,but it is up to different size.

- Q: My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- Steel toe boots around horses is a big no-no! horses are heavy enough to bend the steel and that could possibly cut into her foot. Even if it doesn't cut into her foot, the boot is ruined after the first time a horse does step on it. On the other hand, Mountain Horse and Ariat both make great winter riding boots.

- Q: How are steel coils used in the production of oil and gas pipelines?

- Steel coils are used in the production of oil and gas pipelines as they provide the necessary strength and durability required for transporting petroleum products over long distances. These coils are formed into pipes through various manufacturing processes, such as hot rolling or cold forming, and then welded together to create a continuous pipeline. The high tensile strength of steel coils ensures that the pipelines can withstand the high pressure and harsh environmental conditions associated with oil and gas transportation.

- Q: What is steel made of? What are the elements other than iron?

- Steel is iron and carbon.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: What are the different types of steel coil cutting machines?

- There are several different types of steel coil cutting machines, including slitting machines, shearing machines, and laser cutting machines. Slitting machines are used to cut the steel coil into narrow strips, while shearing machines cut the coil into smaller, more precise lengths. Laser cutting machines use a high-powered laser beam to cut through the steel coil with extreme accuracy. Each type of machine has its own advantages and is suited for specific cutting requirements.

- Q: I plan to buy a bushcraft knife ..The blade made up by damascus steel.My question is ,is damascus steel is very strong ?

- Ok, lets define what is Damascus steel. The modern Damascus is basically any steel that shows a pattern. Patterns are accomplished by 1. manipulating the crystal structure or 2. by combining 2 or more different alloys together. The blade you are looking at is referred to as a pattern welded blade. Damascus is only as strong as it's base components + heat treat and design. The strongest will be obtained by combining high carbon and low carbon steels. I do this by using steel cable. The patterns aren't real bold but are interesting none the less. To break it you must brake the hard steel and tear through the soft iron. The laminated stuff works the same way. For greater edge holding I use all high carbon, varying alloy content from simple carbon to chromium/nickle alloys. These are what you normally find in pattern welded blades. A fine pattern that has many lamination's crossing the edge will offer the best edge holding. Properly done one can get the DCE or damascus cutting effect where the soft layers wear away faster than the hard layers almost making the blade self sharpening. Is that blade good? Buy it if you like it, it won't compare to a well made hand forged blade but is much cheaper. sorry for the overload.

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand depends on the specific type of steel and its intended application. However, generally speaking, steel coils can withstand temperatures ranging from around 500 to 1200 degrees Celsius (932 to 2192 degrees Fahrenheit).

- Q: Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses. Steel coils are not typically affected by low temperatures, as they are durable and resistant to cold weather conditions. However, it is important to ensure that the warehouse is dry and free from moisture, as prolonged exposure to dampness can cause rust and corrosion on the steel coils.

- Q: What are the common sizes of steel coils?

- The common sizes of steel coils vary depending on the specific needs and requirements of different industries. However, there are some standard sizes that are commonly used in the steel manufacturing and processing sectors. These include: 1. Slit Coils: Slit coils are typically smaller in size and are commonly available in widths ranging from 0.5 inches to 72 inches. The weight of slit coils varies, but it is usually between 1000 pounds to 50,000 pounds. 2. Master Coils: Master coils are larger in size and are typically used in steel processing facilities to produce various steel products. The width of master coils usually ranges from 36 inches to 96 inches, while the weight may vary from 5,000 pounds to 60,000 pounds. 3. Sheet Coils: Sheet coils are often used in construction, automotive, and appliance manufacturing industries. The standard sizes for sheet coils vary, but they are commonly available in widths of 48 inches, 60 inches, and 72 inches, with lengths ranging from 96 inches to 240 inches. 4. Plate Coils: Plate coils are primarily used in heavy-duty applications such as shipbuilding, bridge construction, and pressure vessel manufacturing. The sizes of plate coils are typically larger, with widths ranging from 36 inches to 96 inches, and lengths varying from 96 inches to 480 inches. It is important to note that these sizes are not fixed and can be customized based on specific customer requirements. Steel manufacturers and suppliers often have the capability to produce coils in various sizes to meet the diverse needs of their clients.

Send your message to us

Prepainted Galvanized Color Coated PPGI Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords