Prepainted Galvanized Steel Coil for Roofing - Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

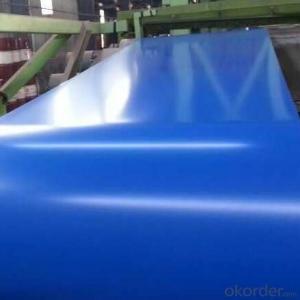

1.Structure of Prepainted Galvanized Steel Coil for Roofing - Hot Sale:

With GI as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized Steel Coil for Roofing - Hot Sale:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Prepainted Galvanized Steel Coil for Roofing - Hot Sale Images:

4.Prepainted Galvanized Steel Coil for Roofing - Hot Sale Specification:

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized Steel Coil for Roofing - Hot Sale:

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q: How are steel coils used in the manufacturing of automotive hoods?

- Steel coils are used in the manufacturing of automotive hoods as the primary raw material. These coils are processed and formed into the desired shape and size to create the hood. The steel's strength and durability make it an ideal choice for automotive hoods, providing protection and structural integrity to the vehicle.

- Q: What are the different types of steel coil coatings available?

- There are several types of steel coil coatings available, including polyester, polyvinylidene fluoride (PVDF), siliconized polyester, plastisol, and acrylic. Each type of coating has its own unique properties and benefits, such as durability, resistance to corrosion and weathering, and aesthetic appeal. These coatings can be applied to steel coils to enhance their performance and appearance in various industries, such as construction, automotive, and appliances.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- Steel is not elemental, if that's what you mean. It's a metal alloy, a combination of mostly iron and some carbon. Iron and carbon both occur naturally on the Earth, but you have to melt them together to make steel.

- Q: So here's the deal:I recently bought McCann's Instant Steel-Cut Oatmeal, and I'm wondering about any possible nutritional differences between the instant and regular stove-top. In case you haven't seen it, instant steel-cut comes in individual packets and is cooked only by adding boiling water, the same as instant rolled oatmeal (i.e. Quaker).When I asked about instant vs. stove-top rolled oats, my doctor said there are no significant nutritional differences, but since the main health appeal of steel-cut is the coarse grain, it doesn't seem possible for the finer ground instant to be as nutritious.I can't find much info about this, so any help is appreciated!

- The rationale for consuming steel cut oats rather than rolled oats (beyond the fact that the former taste really good) is the lower glycemic index. It is my understanding that in the rolled oat category, it is better to eat the long-cooking variety rather the instant for the improved fiber load and lower glycemic index. While I do not understand exactly how instant steel cut oats are processed and how much the glycemic index is affected by processing, it is safe to assume that the old unprocessed steel cut oats are still best. I always prepare 4-6 servings of the steel cut oats at one time and warm up a serving when needed to avoid having to wait 30 minutes to cook them. My rule of thumb: the less processing for any food product, the better it is for me.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Yeah you awaken after the ending cutscene in case you have it put in and then yet another quest line is given to you and you will circulate on your merry way doing in spite of you experience like.

- Q: What are the main steel coil producing countries?

- The main steel coil producing countries are China, Japan, India, the United States, and Russia.

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- Surgical steel is a steel alloy that is free from any metals that are known allergens, such as nickel. It is widely used for surgical instruments and appliances. If you do lend your earrings, they should be sterilized before she wears them, and sterilized again when you get them back.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Metal Soap Bar

- Q: What are the common coil weight and width combinations available for steel coils?

- The common coil weight and width combinations available for steel coils vary depending on the specific industry and application. However, some commonly available coil weight and width combinations for steel coils include weights ranging from 1 to 40 metric tons and widths ranging from 600 to 2,000 millimeters. These combinations can be tailored to meet the requirements of different manufacturing processes and end-user needs.

- Q: If i get a samurai sword made of carbon steel, what is the hardest thing i can hit before it breaks? Or will it not break?

- Carbon steel is an alloy that is made up of the mixture of carbon and iron. In addition, several other elements with low maximum percentages are also included, such as manganese, with 1.65% maximum, silicon,with 0.60% maximum, and copper, with 0.60% maximum. Carbon Steel Pipe Fittings are utilized in a wide variety of applications across multiple industries. They are typically used in large shipyards, fabrication companies, chemical plants, oil refineries, machinery manufacturers, textile, and fluid transportation companies among others. They are highly cost-efficient and are much preferred over other fittings.

Send your message to us

Prepainted Galvanized Steel Coil for Roofing - Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords