Prepainted Galvanized/Aluzing Steel coil for Roofings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Model NO.:G550, FULL HARD, SGHC

Type:Steel Coil

Standard:ASTM, GB, JIS

Certification:ISO, SGS, BV

Surface Treatment:Coated

Technique:Hot Rolled

Special Use:High-strength Steel Plate

Base Metal:Galvanized or Galvalume Steel

Width:914/1000/1200/1219/1220/1250mm

Thickness:0.16-1.2mm

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

Top Side Painting:15-25 Micron

Back Side Painting:5-8 Micron

Colour:Ral Standard or According to Customers′ Requirment

Coil Weight:3-6 Mt

Coil ID:508/610 Mm

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Packing

Standard:0.135-1.2MM

Origin:China, Shandong

HS Code:72107000

Production Capacity:180000mt

Product Description:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-200g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

11. ID: 508/610mm

Specification:

| commodity | Color Coated Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Base metal | galvanized, galvalume, cold rolled steel |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness) |

| Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

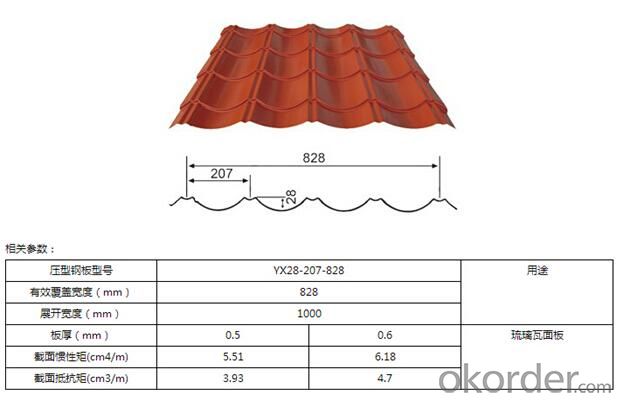

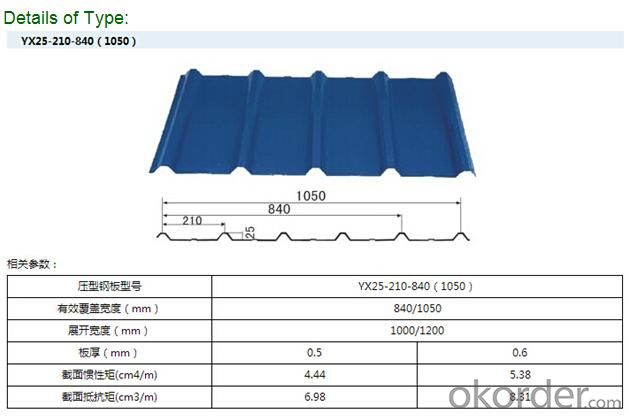

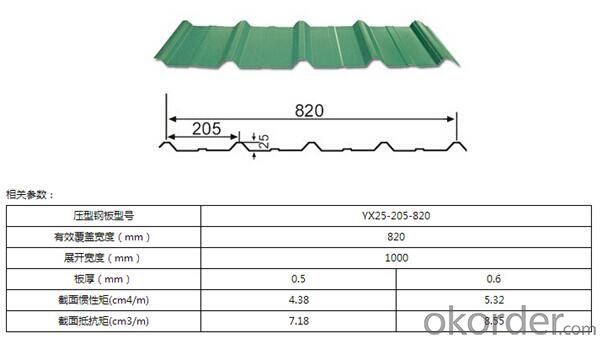

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- If you sprinkle iron filings near a bar magnet (on paper, etc.) the filings will try to line up with the magnetic field (because iron atoms behave like tiny magnets). Bringing the compass near steel (mainly iron with a little carbon) will cause the iron to try to align with the magnet of the compass needle, however, because the needle is free to swing it also aligns with the magnetic field set up between the needle and steel. Any static electricity would have nil effect on the magnetic field.

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel ___ Tompkins xavier jax stone blaise/blaze navarro dialo zorion soloman eron muron darko vincent wolf giovanni ryker/rykeir orvall oryan/orian isadore reese axel/axl xander/zander zane zeke dane xan/zan grayson griffin trayton urban sterling - probably wouldn't sound good with steel but its another choice you can have STOP HATING SHE SAID SHE DIDNT LIKE COMMON NAMES!

- Q: I understand that Stainless Steel is a low carbon steel having minimum 10.5% chromium content in it there r 60 different type of stainless steel. Kindly informa) Is this info correct?????b) Which stainless steel can get rusted or can have superficial rust????

- Stainless steel is a generic term for a whole range (there are more than 60 types) of Fe-Cr alloys. They all contain some amount of C and some alloys include a good number of other alloying elements. In almost all cases, the materials have corrosion resistance due the Cr atoms that are in solid solution with the Fe matrix. Under corrosive conditions, the Cr forms a thin tight coherent layer of Cr-oxide. This Cr oxide coating prevents further corrosion so long as it is not chemically or physically removed. If the SS has been subject to mechanical abrasion, the corrosion resistance can sometimes be restored by a light exposure to nitric acid which passivates the surface, restoring the Cr-oxide layer. The carbon content is an important factor in corrosion preformance but so is the heat treatment. Under the wrong conditions and in different environments, all SSs can rust. One of the most common corrosion problems is sensitization which occurs in the heat affect zone (HAZ) around welds. If the C content is high enough and the heat is high enough, the Cr atoms in solid solution form Cr-carbides and are no longer available to form a protective Cr-oxide. The corrosion resistance can be restored by appropriate heat treatment.

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are used in the manufacturing of electrical wiring to provide strength and support to the wiring. The steel coils are typically used as a core or reinforcement within the wiring to enhance its durability and prevent it from bending or breaking easily.

- Q: How are steel coils cut into smaller sizes?

- Steel coils are cut into smaller sizes using a machine called a slitting line. This machine employs a set of circular blades that cut through the steel coil, creating narrower strips or sheets of the desired size. The slitting line can adjust the width of the cuts and can also remove any rough edges or burrs.

- Q: Can steel coils be perforated?

- Yes, steel coils can be perforated. Perforation is the process of creating small holes or punctures in a material, and steel coils can undergo this process to achieve specific purposes such as enhancing ventilation, improving drainage, or creating decorative patterns.

- Q: How are steel coils used in the production of electrical equipment?

- Steel coils are commonly used in the production of electrical equipment as cores for transformers and inductors. The coils are wound around a steel core to create a magnetic field that allows for efficient energy transfer and voltage regulation. Additionally, steel coils are used in the construction of electric motors, generators, and other electrical components to enhance their performance and durability.

- Q: The difference between aluminized color steel roll and ordinary color steel roll

- Aluminized color coated sheet is a new type of material produced in China in recent years due to its high end applications. It is often used as an indication of CCLI. It is made of galvanized steel sheet (55% aluminum, 43% zinc and 1.6% silicon), which is more galvanized and more corrosion resistant. It is processed by surface degreasing, phosphating and complexing treatment, and is coated with organic coating.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- Hi., I think steel is the best option for the building ..

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Whilst doing a welding course a few years ago the teacher said stainless steel was not its proper name,it is called Heat and Corossion resistant steel,it come in different grades related to its corossion resistance,priced accordingly.Must be welded properly without introduction of carbon to the weld (carbon pickup) or the weld might not be there next time you look dependant on environment.Generally harder to form than mild steel (low carbon steel) so it will tend to be stronger than lcs for the same cross section.steve

Send your message to us

Prepainted Galvanized/Aluzing Steel coil for Roofings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords