Prepainted galvanized Corrugated plate / Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

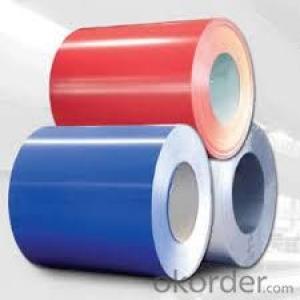

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length,according to the transportation,generally less than 12m

4.color: standard color:red,blue,white,grey; pecial color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: How are steel coils inspected for formability using forming tests?

- To assess their ability to be shaped into desired forms without any defects or failures, steel coils undergo inspections for formability through the use of forming tests. These tests are conducted to evaluate the mechanical properties of the material and determine if it is suitable for specific applications. Forming tests consist of subjecting the steel coil to different forming operations, such as bending, deep drawing, or stretch forming. The coil is typically cut into specific dimensions and then subjected to these operations using specialized equipment. The main objective is to replicate the actual forming process that the steel will experience in real-world applications. During the forming tests, several parameters are carefully monitored. These parameters include the amount of force or load applied, the rate of deformation, and the resulting strain or deformation experienced by the steel. Additionally, the response of the coil to these operations is observed, including any visible defects like cracks, fractures, or surface imperfections. By thoroughly analyzing the performance of the steel coil during the forming tests, various characteristics related to formability can be determined. These characteristics include the material's ability to resist deformation, its capacity to withstand strain without failure, and its tendency to exhibit defects under specific forming conditions. The results obtained from these tests provide valuable insights into the suitability of the steel coil for particular forming processes and applications. Furthermore, advanced techniques such as digital image correlation and strain analysis can be utilized to precisely measure and evaluate the distribution of strain across the surface of the steel coil. These techniques assist in identifying areas of the coil that experience higher strain and potential points of failure. In summary, the formability of steel coils is assessed through forming tests that simulate the actual forming processes they will undergo. These tests evaluate various formability characteristics, including the material's resistance to deformation and its likelihood of defects. The results obtained from these tests aid in determining the suitability of the steel coil for specific applications and guide the selection of appropriate forming parameters.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being uncoiled and then fed into a machine that cuts and forms the bolts. The coils provide a continuous supply of high-quality steel, ensuring consistent and precise production of bolts.

- Q: How long do steel coils typically last?

- Steel coils typically last for decades. The lifespan of steel coils can vary based on several factors including the quality of the steel used, the level of maintenance and care, and the specific application they are utilized in. Generally, steel coils are designed to be durable and resistant to corrosion, ensuring a long lifespan. With proper care, regular maintenance, and adherence to recommended usage guidelines, steel coils can last anywhere from 20 to 50 years or even longer. However, it is important to note that the lifespan can be influenced by external factors such as exposure to harsh environments, extreme weather conditions, and the level of stress or load they are subjected to.

- Q: What are the dimensions of steel coils used in the household appliance industry?

- The dimensions of steel coils used in the household appliance industry can vary depending on the specific application and manufacturer. However, common dimensions for steel coils in this industry range from 0.20mm to 3.0mm in thickness and 600mm to 1500mm in width.

- Q: How are steel coils used in the production of steel tanks?

- Steel tanks rely on steel coils as a vital element in their production. These coils, typically made from top-notch steel, act as the primary raw material for manufacturing steel tanks. The initial step involves unrolling and flattening the steel coils, which are usually supplied in a coiled form from the steel mills. Once unrolled, the coils are then cut into specific lengths and widths, depending on the desired dimensions of the steel tank. These cut pieces are molded and shaped into various tank components, including the cylindrical body, top and bottom ends, and additional fittings or accessories. The strength and durability of the tank heavily depend on the steel coils, ensuring its ability to withstand the demands of its intended use. The quality of the steel used in the coils is pivotal as it determines the tank's resistance to corrosion, pressure, and external forces. Additionally, employing steel coils enables efficient and cost-effective manufacturing of steel tanks. The standardized nature of the coils ensures consistent quality and dimensions, streamlining the production process. Precise cutting of the coils also minimizes waste and maximizes material utilization. Furthermore, steel coils offer design flexibility and customization options. They are easily formed and welded into intricate shapes, accommodating tanks of varying sizes, capacities, and configurations. This versatility makes steel coils the ideal choice for producing tanks across diverse sectors, including industrial, commercial, and residential applications. In conclusion, steel coils play a critical role in steel tank production. They provide the necessary raw material for manufacturing different tank components, guaranteeing strength, durability, and customization. By utilizing steel coils, manufacturers can efficiently produce high-quality tanks that meet the specific requirements of various industries.

- Q: What are the different methods of corrosion protection for steel coils?

- There are several different methods of corrosion protection for steel coils, each with its own advantages and disadvantages. 1. Coating: One of the most common methods is to apply a protective coating to the steel coils. This can be done through a variety of techniques such as hot-dip galvanizing, electroplating, or painting. Coatings provide a barrier between the steel surface and the corrosive environment, preventing direct contact and thus reducing the risk of corrosion. 2. VCI (Vapor Corrosion Inhibitor): Another method is the use of VCI materials, which release chemicals that inhibit corrosion when in contact with the steel surface. These materials can be applied as coatings, films, or papers, and are particularly useful for long-term storage or shipping of steel coils. 3. Cathodic Protection: This method involves the use of sacrificial anodes or impressed currents to protect the steel coils. Sacrificial anodes, typically made of zinc or aluminum, are connected to the steel surface. These anodes corrode instead of the steel, sacrificing themselves to protect the coils. Impressed current systems use a direct electrical current to prevent corrosion on the steel surface. 4. Wrapping and Packaging: Proper wrapping and packaging of steel coils can also provide corrosion protection. This includes using moisture barrier films, desiccants, or absorbent materials to reduce the moisture content around the coils. Additionally, ensuring adequate ventilation and avoiding contact with other corrosive substances can help prevent corrosion. 5. Environmental Control: Controlling the environment in which the steel coils are stored or used is crucial for corrosion protection. This may involve maintaining proper humidity levels, controlling temperature, and managing air quality. By minimizing exposure to corrosive elements such as moisture, salts, or chemicals, the risk of corrosion can be significantly reduced. It is important to note that the choice of corrosion protection method depends on various factors such as the specific application, budget constraints, and desired lifespan of the steel coils. A combination of these methods may also be used to provide enhanced protection against corrosion.

- Q: How do steel coils contribute to durability and longevity in products?

- The durability and longevity of products are greatly enhanced by steel coils, mainly because of their strength, stability, and resistance to corrosion. Firstly, steel is widely known for its exceptional strength, making it the perfect material for applications where durability is crucial. Steel coils, which are essentially tightly rolled steel, add strength and structural integrity to products. The stability offered by steel coils is another important factor in improving product durability. The tightly rolled structure of the coils ensures that they maintain their shape and resist deformation even under heavy loads or extreme conditions. This stability is particularly significant in industries like construction and automotive, where products need to withstand rigorous usage for long periods of time. Furthermore, steel coils have excellent resistance to corrosion, primarily due to the presence of protective coatings. These coatings, such as zinc or other metallic alloys, act as a barrier against moisture and environmental elements that cause rust and degradation. By preventing corrosion, steel coils help extend the lifespan of products, making them more durable and reliable. Moreover, steel coils can be customized to meet specific requirements, such as different thicknesses, widths, or surface finishes. This versatility allows manufacturers to tailor the steel coils to their desired application, ensuring optimal performance and longevity in their products. To sum up, steel coils contribute to the durability and longevity of products through their strength, stability, corrosion resistance, and customization capabilities. By incorporating steel coils into various industries and applications, manufacturers can ensure that their products last longer and provide greater reliability to consumers.

- Q: How are steel coils tested for strength and durability?

- Steel coils are typically tested for strength and durability through a series of rigorous procedures such as tension and compression tests, hardness tests, and impact tests. These tests help determine the coil's ability to withstand various loads and impacts, ensuring that it meets the required strength and durability standards. Additionally, other tests like fatigue tests and corrosion resistance tests may also be conducted to further assess the coil's performance and longevity.

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are inspected for coil weight accuracy after processing through the use of weighing scales or load cells. These devices measure the weight of the coil and compare it to the predetermined weight specifications. If the weight falls within the acceptable range, the coil is deemed accurate.

- Q: What are the common coil surface treatments available for steel coils?

- Steel coils can be treated with various methods to improve their durability, resistance to corrosion, and appearance. These treatments serve different purposes and offer different benefits. 1. Galvanized Coating: A layer of zinc is applied to the surface of the steel coil, providing excellent protection against corrosion. This coating is commonly used in outdoor applications or high humidity environments to prevent rust and increase the coil's lifespan. 2. Phosphating: A chemical treatment that creates a thin layer of phosphate coating on the steel coil's surface. This treatment improves the adhesion of subsequent coatings and enhances the coil's paintability. It also offers some corrosion resistance and can be used as a pre-treatment before painting or powder coating. 3. Chromate Conversion Coating: Also known as chem film or Alodine, this treatment involves applying a thin layer of chromate to the steel coil's surface. It provides corrosion protection and acts as a primer for other coatings, improving their adhesion. It is commonly used in aerospace and electrical applications. 4. Powder Coating: In this dry finishing process, a fine powder is electrostatically applied to the steel coil's surface and then cured under heat. The result is a durable and attractive finish that offers excellent resistance to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile option. 5. Organic Coatings: Liquid paints such as acrylic, polyester, or polyurethane are applied to the steel coil's surface. These coatings provide aesthetic appeal, protection against corrosion, and resistance to weathering and UV radiation. They are commonly used in architectural and automotive applications. 6. Anodizing: Primarily used for aluminum coils, anodizing can also be applied to steel coils. This treatment involves creating an oxide layer on the coil's surface through an electrochemical process. It enhances corrosion resistance and provides an attractive finish. Anodizing is commonly used in architectural and decorative applications. It's important to consider specific requirements, including performance, aesthetics, and environmental factors, when choosing a coil surface treatment. Consulting with a professional in the steel industry can help determine the most suitable treatment for a particular project.

Send your message to us

Prepainted galvanized Corrugated plate / Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords