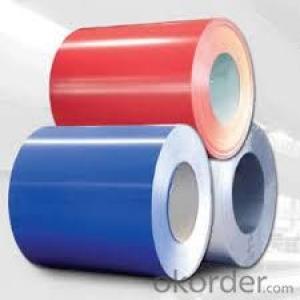

Prepainted Galvanized corrugated Plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.material :

galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness :

normal use 0.3-0.6mm

3.length:

any length,according to the transportation,generally less than 12m

4.color:

standard color:red,blue,white,grey

special color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: Can the steel sheets be easily cleaned?

- Certainly, steel sheets can be effortlessly cleaned. Renowned for their durability and low-maintenance nature, steel sheets can be swiftly wiped down with a damp cloth or sponge accompanied by mild soap or detergent. In the case of stubborn stains or grime, a non-abrasive cleaner is recommended. Moreover, steel sheets exhibit exceptional resistance to rust and corrosion, rendering them well-suited for diverse settings and ensuring hassle-free maintenance in the long term.

- Q: What is the standard size of steel sheets?

- The standard size of steel sheets can vary depending on the specific application and industry. However, a common standard size for steel sheets is typically around 4 feet by 8 feet.

- Q: Can steel sheets be used in renewable energy applications?

- Yes, steel sheets can be used in renewable energy applications. Steel is widely used in the construction of wind turbines, solar panels, and other renewable energy infrastructure. It is durable, strong, and can withstand harsh environmental conditions, making it a suitable material for these applications. Additionally, steel is recyclable, which aligns with the sustainability goals of renewable energy projects.

- Q: What are the different profile options available for steel sheets?

- Steel sheets come in various profile options, each serving distinct purposes and offering unique advantages. Some commonly used profiles are: 1. Plain Sheet: This is the most basic option with a flat surface and no additional features. It is commonly employed for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: These sheets have parallel ridges and grooves, forming a wavy pattern. They provide extra strength and rigidity, making them ideal for roofing, cladding, and fencing. The ridges also facilitate water shedding, preventing water accumulation. 3. Ribbed Sheet: Ribbed sheets have raised parallel ridges or ribs along their length. This profile offers enhanced strength and load-bearing capacity, making it suitable for applications requiring structural integrity, like mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated sheets have a pattern of punched holes, allowing for ventilation, light transmission, and drainage. They are commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have an embossed pattern of lines or diamonds on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, commonly used for framing, shelving, and edge protection. These are just a few examples of the available profile options for steel sheets. The choice of profile depends on specific requirements such as strength, durability, aesthetics, and functionality.

- Q: How do steel sheets resist fire?

- Steel sheets resist fire due to their high melting point and excellent heat conductivity. When exposed to fire, the steel sheets absorb and conduct heat away from the source, preventing the temperature from rising to a critical level where the steel would weaken or melt. Additionally, steel does not combust or release toxic gases when heated, further enhancing its fire resistance.

- Q: Are the steel sheets suitable for outdoor applications?

- Certainly, steel sheets prove to be a fitting option for outdoor applications. Boasting durability and strength, steel emerges as a material capable of withstanding diverse weather conditions and environmental elements. Its resistance to rust and corrosion renders it particularly ideal for outdoor utilization. Moreover, steel sheets can be subjected to treatment or coating processes, thereby augmenting their resilience against moisture and other external factors, further amplifying their appropriateness for outdoor applications. Whether the purpose entails construction, manufacturing, or decorative endeavors, steel sheets present themselves as a dependable selection for outdoor projects.

- Q: What is the weight of a steel sheet?

- The weight of a steel sheet can vary depending on its dimensions and thickness.

- Q: What industries commonly use steel sheets?

- Some of the industries that commonly use steel sheets include construction, automotive, manufacturing, aerospace, and energy sectors.

- Q: Are the steel sheets available in different thickness tolerances?

- Certainly, there are various thickness tolerances for steel sheets that are readily available. Steel producers create sheets with diverse thicknesses to accommodate different purposes and demands. These tolerances are determined by established standards within the industry and can differ based on the steel type and intended application. In construction, for instance, tighter tolerances might be mandatory to guarantee the structural soundness, while in manufacturing sectors like automotive or aerospace, precise tolerances may be indispensable to meet design requirements. Through offering steel sheets in varying thickness tolerances, manufacturers allow customers to select the most fitting product for their individual requirements.

- Q: Can steel sheets be painted after installation?

- Yes, steel sheets can be painted after installation. The paint can adhere to the surface of the steel sheets, providing protection against corrosion and enhancing their appearance.

Send your message to us

Prepainted Galvanized corrugated Plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords