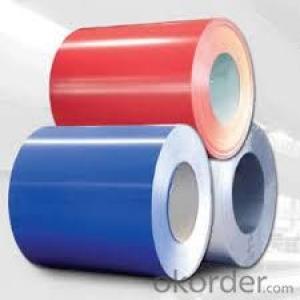

Prepainted Galvanized corrugated plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.material :

galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness :

normal use 0.3-0.6mm

3.length:

any length,according to the transportation,generally less than 12m

4.color:

standard color:red,blue,white,grey

special color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: How are steel coils used in the production of steel wire?

- Steel coils are used in the production of steel wire by being unwound and fed into a wire drawing machine. The coils provide a continuous and consistent supply of steel, which is passed through a series of dies to reduce its diameter and increase its strength. This process is repeated multiple times until the desired wire diameter is achieved.

- Q: Can steel coils be coated with anti-static materials?

- Yes, steel coils can be coated with anti-static materials. Anti-static coatings are often used to reduce or eliminate static electricity buildup on surfaces, including steel coils. These coatings help to prevent the accumulation of dust, reduce the risk of electrical discharge and sparks, and ensure the safe handling and storage of steel coils in various industries.

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Rock pokemon are weak against steel type moves.

- Q: How are steel coils coated?

- Steel coils are typically coated through a process known as coil coating, which involves applying a protective layer to the surface of the steel. This is done by passing the coil through a series of rollers that apply the coating material evenly across the entire surface. The coating can be applied using various methods such as roll coating, spray coating, or electrostatic coating, depending on the desired finish and properties. The coated steel coils are then cured or baked to ensure the coating adheres properly and provides the desired level of protection and durability.

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks as they provide the raw material needed for shaping, forming, and manufacturing the hooks. The coils are unwound, processed, and then transformed into the desired shape and size to create the steel hooks.

- Q: What is the typical size and weight of a steel coil?

- The specific application and industry play a role in determining the varying size and weight of a steel coil. Generally, steel coils are manufactured with widths that range from 0.5 to 2 meters (1.6 to 6.6 feet) and can weigh anywhere between 1 to 25 metric tons (2,205 to 55,116 pounds). The size and weight of a steel coil are influenced by factors such as the type of steel utilized, the intended purpose of the coil, and the manufacturing method employed.

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- i think steel would be better since there isn't a lot of mithril ore and it would take a lot of time to mine it and it will take also 4 coals to make a mith bar and 2 only for a steel bar

- Q: How do steel coils contribute to the aerospace manufacturing industry?

- Steel coils are essential in the aerospace manufacturing industry as they are used to produce various components, such as aircraft bodies, wings, and landing gear. These coils provide the necessary strength, durability, and resistance to extreme conditions required for aerospace applications. Additionally, steel coils can be easily shaped and welded, enabling manufacturers to create complex and precise structures, thereby enhancing the safety and efficiency of aircraft.

- Q: What are the advantages of using steel coils in the manufacturing industry?

- There are several advantages of using steel coils in the manufacturing industry. Firstly, steel coils provide excellent strength and durability, making them ideal for applications that require high load-bearing capacity. Secondly, steel coils are highly resistant to corrosion, making them suitable for outdoor or harsh environments. Additionally, steel coils offer consistent and uniform properties, ensuring reliable and precise manufacturing processes. Moreover, steel coils can be easily formed and shaped, allowing for versatile use in various industries. Lastly, steel coils are recyclable, making them an environmentally friendly choice.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless okorder /

Send your message to us

Prepainted Galvanized corrugated plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords