Prepainted Aluminum Steel Sheets PPGL 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Coil PPGL Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Coil PPGL:

1) Perfect weather ability, high strength, no special maintenance

2) Convenient construction, short working time

3) Excellent machining heat insulation, sound insulation property and perfect fireproof performance

4) High plasticity, good impact resistance, quakeproof performance and reducing buildings load

5)Goods smoothness, lightweight and rigid, beautiful and cheap

6) Various colors available

7) Simple machining equipments, processing in spot.

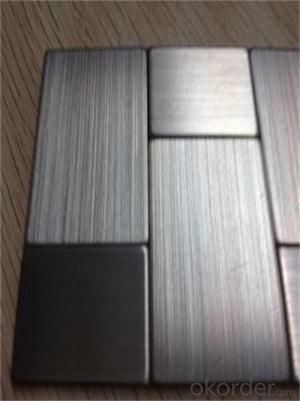

Images of Aluminium Coil PPGL:

Aluminium Coil PPGL Specification:

Product Name | Aluminum Coil |

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of Aluminium Coil PPGL:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

- Q: How do you store aluminum sheets?

- When storing aluminum sheets, it is crucial to take into account their size, weight, and overall condition. Below are some guidelines to follow: 1. Find an appropriate location: Locate a dry and well-ventilated area indoors with stable temperatures. This will prevent moisture and humidity from causing corrosion or harm to the aluminum sheets. 2. Guard against moisture: Wrap each aluminum sheet individually with plastic or moisture-resistant sheets. This will create a barrier against moisture and prevent potential corrosion. Avoid using materials that may react with aluminum, such as acidic or alkaline substances. 3. Arrange and stack: If you have multiple aluminum sheets, consider organizing them based on size, thickness, or other relevant factors. This will make it easier to access specific sheets without disturbing the entire stack. Place larger and heavier sheets at the bottom to prevent any potential damage. 4. Utilize racks or pallets: For a larger quantity of aluminum sheets, using racks or pallets can provide additional support and stability. Ensure that the racks or pallets are strong enough to handle the weight and designed to prevent deformation or bending of the sheets. 5. Label and document: Label each sheet with relevant information such as size, thickness, or specific details. Additionally, maintain a detailed inventory or catalog of your aluminum sheets to easily locate and retrieve specific ones when needed. 6. Regularly inspect: Periodically inspect your stored aluminum sheets to ensure they remain in good condition. Look for signs of corrosion, damage, or any other issues that may require immediate attention. By following these steps, you can effectively store aluminum sheets, safeguarding them from damage and ensuring their longevity.

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration due to their inherent strength and durability. The high stiffness-to-weight ratio of aluminum, along with its ability to dampen vibrations, makes it an ideal material for applications requiring vibration resistance.

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: Can aluminum sheets be polished?

- Certainly, aluminum sheets are capable of being polished. Aluminum, being a relatively malleable metal, lends itself to easier polishing in comparison to harder metals like stainless steel. The act of polishing aluminum sheets entails the utilization of abrasive substances such as sandpaper or polishing compounds. This serves to eliminate any blemishes, scratches, or oxidation present on the surface. Typically, the process involves multiple stages of polishing, employing varying degrees of grit in sandpaper or polishing compounds. Step by step, a smoother and more reflective surface is attained. Polished aluminum sheets find common usage in various applications, including automotive components, architectural elements, and ornamental objects. The polishing process elevates the metal's aesthetic appeal, imparting a glossy and reflective finish.

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q: there is a magnet for other type of nails except aluminum nails

- Aluminum can't be magnetized - it's not ferrous. Put a piece of old pantyhose over the hose of a vacuum and vacuum the area... the nails will be picked up by the suction, but not sucked into the hose. Then you can just tale them off.

- Q: To an idiot, this may seem like a stupid question: its just aluminum. But it may not be.However seeing that I am only a high school student and don't have access to aluminum power (which is what I desire for an independent experiment) so I'd like to grind consumer grade aluminum foil down bases of Mohs scale of Hardness.My concern is that aluminum foil is Aluminum oxide which is a 9 (10 being diamond, 1 being talcum powder) and this would be horribly difficult to grind.If it is Alumina, that's only a 3.5.If it does happen to be aluminum oxide, can you think of a way to remove the Oxygen. Would nitric acid work.

- It is not aluminum oxide. It's pretty much pure aluminum, though it may be coated with a very thin layer of wax or plastic. As for the independent experiment, be careful and wear goggles and other protective clothing. I was in high school once too, and can tell you from experience that thermite burns very, very hot and is quite good at melting or combusting a wide variety of materials. It also requires a fairly hot ignition source, and magnesium strips are often used for that purpose as a kind of fuse. If you don't have access to that, figure something else out, but do *not* attempt to light thermite directly with a blowtorch. You want to be much farther away by the time it lights, and it would be a bad idea to lay the torch there and back away because that places the torch's potentially explosive fuel supply much too close to the reaction.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets possess remarkable fire-resistant properties, making them an excellent choice for various applications where fire safety is a concern. The primary reason for their fire resistance is the unique oxide layer that forms naturally on the surface of the aluminum when exposed to oxygen. This layer acts as a protective barrier, preventing the metal from further oxidation and reducing the potential for combustion. The oxide layer on aluminum sheets is not only highly stable but also has a high melting point. This means that it can withstand high temperatures without melting or igniting, making it resistant to flames. Furthermore, the oxide layer is an effective thermal insulator, which helps to slow down heat transfer and prevent the spread of fire. Another advantage of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning that it does not burn or support combustion. This property is particularly beneficial in situations where fire containment and prevention are crucial. Moreover, aluminum sheets have excellent heat dissipation capabilities. They quickly dissipate heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications such as electrical enclosures, automotive parts, and industrial machinery. In summary, aluminum sheets exhibit outstanding fire-resistant properties due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These properties make them highly desirable for applications where fire safety is essential, providing peace of mind and protecting against potential fire incidents.

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

Send your message to us

Prepainted Aluminum Steel Sheets PPGL 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords