Brushed Aluminum Adhesive Sheets Prepainted Aluminum Coil Aluminum Sheet PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Prepainted Aluminium Coil PPGL Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

Main Features of Aluminium Coil PPGL:

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect

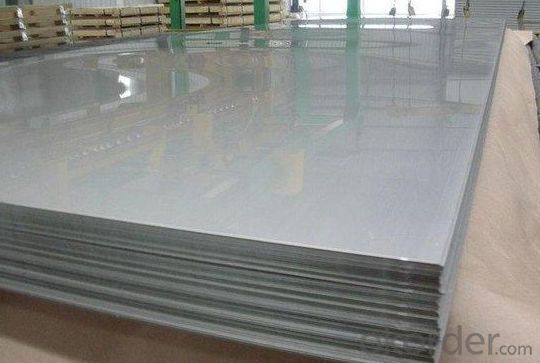

Images of Aluminium Coil PPGL:

Aluminium Coil PPGL Specification:

Product Name | Aluminum Coil |

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

Specifications:

Hardness(HV) , Tensile Strength(N/mm2,MPa) , Elongation(%) ,

Proof Stress , Surface Finish ,

Edge Condition(Slited Edge, Rolled Edge, De-burred Edge, etc.) ,

Camber(mm/1M) , Cross bow(mm/Width) , Coil set(mm/1M) ,Surface Roughness(Rmax, Rz, Ra)

Maximum OD , Coil Weight , Packing

FAQ of Aluminium Coil PPGL:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Marine vessel construction greatly benefits from the utilization of aluminum sheets. With its exceptional corrosion resistance properties, aluminum proves itself as the ideal material for saltwater environments. Its lightweight nature combined with its strength strikes a perfect balance between durability and weight reduction, resulting in improved fuel efficiency and increased payload capacity. Moreover, shipbuilders favor aluminum due to its ease of fabrication, welding, and repair. Its high strength-to-weight ratio and ability to withstand extreme temperatures also render it suitable for various marine applications, including hulls, decks, superstructures, and other structural components. All in all, the use of aluminum sheets in marine vessel construction presents numerous advantages, establishing it as a favored choice within the maritime industry.

- Q: Is it possible to utilize aluminum sheets as a material for constructing roofs?

- <p>Yes, aluminum sheets can be used for roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also energy-efficient, reflecting heat and reducing cooling costs. It's recyclable and has a long lifespan, making it an environmentally friendly choice. However, it may not be as impact-resistant as some other materials and can be more expensive upfront.</p>

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: What is the width and length of the aluminum sheets?

- The width and length of the aluminum sheets may vary depending on the specific product or manufacturer. It is recommended to refer to the product specifications or contact the manufacturer for accurate measurements.

- Q: What are aluminum sheets used for?

- Due to their unique properties and versatility, aluminum sheets find a wide range of uses. In the construction industry, they are commonly employed for roofing, siding, and cladding, thanks to their lightweight nature, corrosion resistance, and durability. These qualities make them ideal for such purposes. In the transportation industry, aluminum sheets are widely utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. They also serve as a lightweight yet sturdy solution for trailers, truck bodies, and shipping containers. Another significant application of aluminum sheets lies in the manufacturing of consumer products. They are used to make household appliances, cookware, and electronics, as they possess excellent thermal conductivity and resistance to rust and corrosion. Additionally, their ability to withstand various weather conditions makes them suitable for the production of signage, billboards, and displays. In the packaging industry, aluminum sheets play a crucial role in the production of cans, foils, and lids. Their impermeability to light, moisture, and oxygen helps preserve the freshness and quality of food and beverages. Moreover, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Additionally, their thermal and electrical conductivity makes them suitable for the production of heat exchangers, solar panels, and electrical conductors. In summary, aluminum sheets find application in construction, transportation, consumer products, packaging, and various industrial sectors, owing to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Q: Is it possible to utilize aluminum sheets in a home renovation project?

- <p>Yes, you can use aluminum sheets for your home renovation project. Aluminum is a versatile material known for its strength, durability, and resistance to corrosion. It's commonly used for roofing, siding, and even for decorative purposes. Aluminum sheets are lightweight, easy to install, and can be painted or coated to match your home's aesthetic. They also offer good thermal performance and can be recycled, making them an environmentally friendly choice. However, it's important to consider the specific requirements of your project, such as the local climate, design preferences, and budget, to ensure aluminum is the best fit.</p>

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring materials. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum floors are often used in commercial and industrial settings due to their strength and ability to withstand heavy loads. They are also favored for their slip resistance and non-flammable properties, making them a safe choice for various applications. However, they may not be as common in residential settings due to cost and the鍐板喎 feel underfoot compared to traditional flooring materials like wood or carpet.</p>

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- try GOJO hand cleaner with a Sung. you dont need to scrub hard and it will remove the baked on grease.

Send your message to us

Brushed Aluminum Adhesive Sheets Prepainted Aluminum Coil Aluminum Sheet PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords