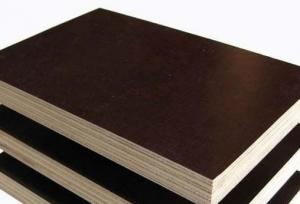

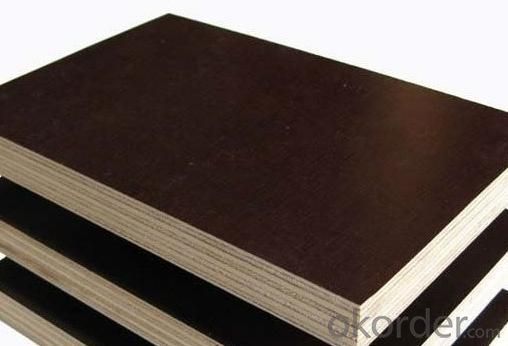

High Quality Concrete Formwork Plywood

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Pieces cm²

- Supply Capability:

- 5000 Piece/Pieces per Day cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 . Introduction of High Quality Concrete Formwork Plywood

High-grade raw materials;

High quality, low price;

Dimensional stability.

Concrete formwork plywood

2 . SPECIFICATION OF High Quality Concrete Formwork Plywood

1) Core:Poplar,Combi,Hardwood

2) Film: Brown,Black,Red

3) Size: 1220*2440/ 915*2135/ 1250*2500MM

4) Thickness: 18/21MM

5) Thickness tolerance:Minus or plus 0.2-0.5MM

6) Moisture content: 8%-12%

7) Quantity: 8pallets/20FT,16pallets/40FT,18pallets/40HQ

8) Packing: Negotiable

9) GLUE:WBP phenolic,MR,E1,E2.

10) Price advantage: 20-30% cheaper than others based on same quality

11) Design ability: We can offer you a general proposal based on your structural drawings

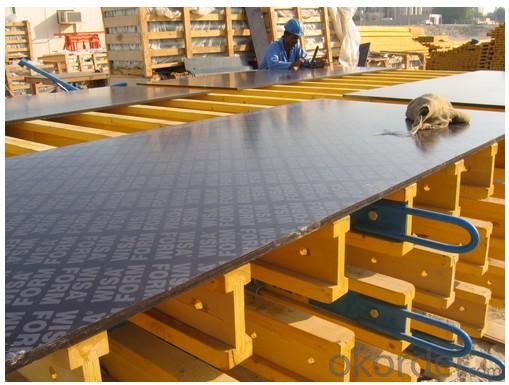

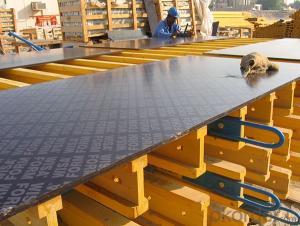

3 . CHARACTERISTICS OF High Quality Concrete Formwork Plywood:

This plywood can be used at timber beam system,steel formwork system,aluminum frame slab formwork.

Component with high standardization

Assembling in site,flexible application

Light weight,easy transportation and storage

Used with timber beam system step 1

Used with timber beam system step 2

Used with timber beam system step 3&4

4 . PROJECT APPLICATION OF High Quality Concrete Formwork Plywood

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

Send your message to us

High Quality Concrete Formwork Plywood

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Pieces cm²

- Supply Capability:

- 5000 Piece/Pieces per Day cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords