Pre-painted Galvanized Steel Sheet Coil with Prime Quality and Best Price, Red Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

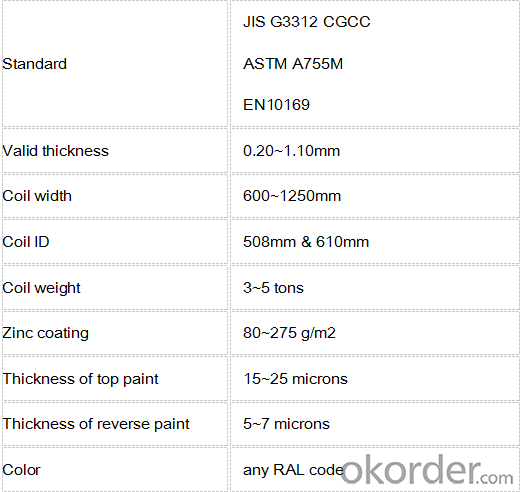

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the manufacturing of agricultural silos?

- Steel coils are used in the manufacturing of agricultural silos by being formed and shaped into corrugated sheets, which are then assembled into the walls of the silo. The strength and durability of the steel coils ensure that the silo can withstand the weight of the stored grains and withstand external pressures.

- Q: How do steel coils contribute to the energy storage industry?

- The energy storage industry benefits greatly from the use of steel coils in multiple ways. Initially, steel coils are instrumental in the fabrication of energy storage systems like batteries. Through their steel casing, batteries are provided with both structural support and protection for the battery cells, ensuring their safety and longevity. If not for steel coils, batteries would be more susceptible to damage and unable to function efficiently. Furthermore, the construction of flywheels, an alternative form of energy storage technology, heavily relies on steel coils. Flywheels store energy by spinning a rotor at high speeds and releasing the stored energy when necessary. Steel coils are employed to create the rotor, which necessitates strength, durability, and the ability to withstand substantial rotational forces. Additionally, the magnetic properties of steel contribute to the enhancement of energy transfer efficiency within the flywheel system. Moreover, compressed air energy storage (CAES) systems also utilize steel coils in their production. CAES systems store energy by compressing air and releasing it to generate electricity upon demand. Steel coils are crucial in constructing the air storage chamber, guaranteeing its integrity and preventing any leakage or damage. The robust nature of steel coils makes them ideal for enduring the high pressures associated with the compression process. To summarize, the energy storage industry greatly benefits from the utilization of steel coils. They provide essential structural support, durability, and protection to various energy storage technologies, whether it be batteries, flywheels, or CAES systems. By contributing to the efficient and secure storage of energy, steel coils facilitate the advancement and adoption of sustainable energy solutions.

- Q: i got the belly button ring from icing and its surgical steel are they the same things?

- yes they are same kind of steel

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You can use steel but alloyed with a big percent of Mn and Cr. Titanium is very good but unfortunately it is expensive. On engines and Turbine blades it is indicate to use High Alloy metals that are resistant to fluage.

- Q: What are the factors affecting the corrosion resistance of steel coils?

- There are several factors that can affect the corrosion resistance of steel coils. These factors include the composition of the steel, the presence of impurities or alloying elements, the surface finish or coating on the coils, the environmental conditions such as humidity and temperature, and the presence of corrosive chemicals or substances in the surrounding atmosphere. Additionally, factors such as handling and storage practices can also impact the corrosion resistance of steel coils.

- Q: What are the common methods of joining steel coils?

- Various techniques can be employed to join steel coils, depending on the desired outcome and specific application. Butt welding is a commonly utilized method wherein the two ends of the steel coils are aligned and welded together. Gas welding, electric resistance welding, or laser welding can be employed for this purpose. This technique yields a strong and continuous joint without the need for additional material. For temporary or low-stress applications where disassembly may be necessary, overlapping and stitching is an option. In this technique, one end of the steel coil is overlapped onto the other end and fastened together using mechanical means such as staples, nails, or screws. Mechanical couplings are another means of joining steel coils. These couplings are designed to fit over the coil ends and securely hold them together. They are commonly used in pipelines where the joint must be leak-proof and capable of withstanding high pressure. Adhesive bonding is a method that involves applying a suitable adhesive or bonding agent to the coil ends and pressing them together. This technique results in a clean and visually appealing joint, although the strength may vary depending on the adhesive used. Similar to overlapping and stitching, overlapping and welding involves overlapping the coil ends and welding them together. However, instead of using mechanical fasteners, welding is employed to create a stronger and more permanent joint. This method is frequently employed in structural applications that require high strength and durability. It should be noted that the selection of a joining method depends on factors such as the type of steel, application requirements, and desired joint strength. Careful consideration should be given to ensure that the chosen method is suitable for the specific project.

- Q: How are steel coils inspected for width?

- Steel coils are inspected for width using various methods to ensure they meet the required specifications. One common method is to use a caliper gauge, also known as a micrometer, which measures the width of the coil by physically contacting its edges. The operator places the caliper gauge at various points along the width of the coil and records the measurements. This method allows for precise measurements and helps identify any inconsistencies or deviations from the desired width. Another method used for inspecting steel coil width is laser measurement. Laser sensors are positioned on both sides of the coil, and they emit a laser beam that scans across the width of the coil. The sensors detect the distance between the coil's edges and provide accurate width measurements. This non-contact method is highly efficient and can quickly inspect the width of the coil without any physical contact or potential damage. In addition to these methods, some advanced systems use computer vision technology for width inspection. Cameras and image processing software are employed to capture images of the coil's edges. The software analyzes these images and calculates the width based on the detected edges. This method allows for high-speed inspections and can detect any irregularities in the width of the coil. Overall, steel coils are inspected for width using a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils meet the required width specifications and help maintain quality control in the steel manufacturing process.

- Q: I believe steel is stronger but it steel lighter than iron too?

- Steel is iron, with other things added that strengthen it and/or make it less rust liable. So, in general, steel is stronger than iron. In so far as the density, that depends on the steel alloy. Some are higher than iron, some lower. Remember there are hundreds of different steel alloys. edit: but the density is still close to that of iron. density steel 7750 to 8050 kg/m? density iron 7870 kg/m?

- Q: I have a set of Stainless steel pots and pans. Everything is sticks to them. What must I do so things don't stick?

- a good de-greasing cleansing soap, a pad of metal wool, some warm water, and elbow grease will do the interest. Or once you've really one of those steamer gadgets, it truly is going to fantastically a lot melt off. And when you've them wiped clean up, somewhat Bon Ami and a scouring pad used each now and then will stay away from the upward thrust from returning. yet another good product is Twenty Mule team Borax oftentimes discovered close to the laundry products.

- Q: How do steel coils contribute to the aerospace industry?

- Steel coils contribute to the aerospace industry by being used in the manufacturing of various aircraft components such as engine parts, landing gear, and structural elements. The high strength and durability of steel make it a preferred material for these applications, ensuring the safety and reliability of aircraft. Additionally, steel coils are also used in the production of specialized tools and equipment required for aerospace manufacturing processes.

Send your message to us

Pre-painted Galvanized Steel Sheet Coil with Prime Quality and Best Price, Red Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords