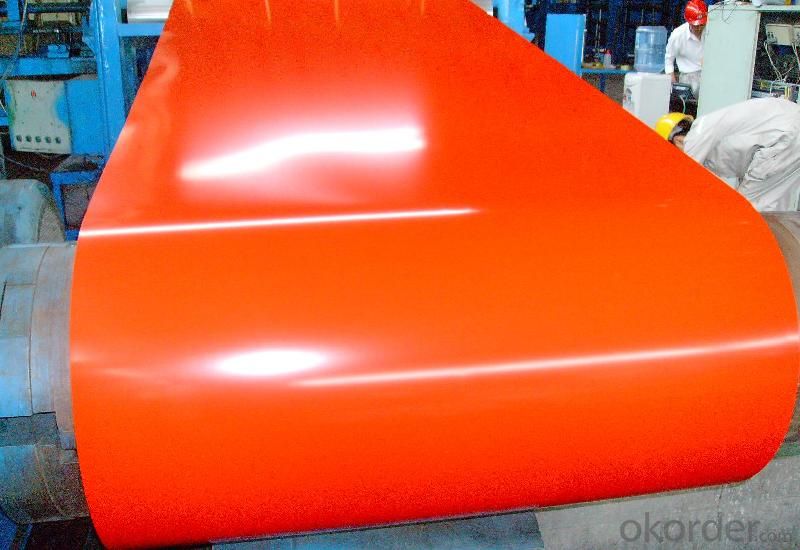

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with P r ime Quality and Lowest Price Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Surface finish: with or without protect film

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Thickness : 0.14-1.20 mm

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- Carbon steel chef's knives out perform stainless in every aspect except 1, care. You can't put them in a dishwasher. Wash, rinse and dry off. Do not keep them in a drawer filled with other kitchen stuff, rather, keep them in a cabinet or block. If it starts to rust you can use steel wool to clean them up, or fine grit sandpaper if you want to retain a fine finish. For your viewing pleasure, a chef's knife I forged from crane cable.

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- Of course wood+1

- Q: I need the measurements of the height and hypotenuse of the first drop in the Steel Dragon 2000. I couldn't find it anywhere. It would be great if you could also show me the website where you got your answer. Thanks! =]*The hypotenuse is the length of the drop.*

- Steel Dragon 2000 is a roller coaster at Nagashima Spa Land Amusement Park in Mie Prefecture, Japan. Built by Morgan Manufacturing, this gigacoaster opened, appropriately, in 2000 - The Year of the Dragon in the Far East. It debuted only months after Millennium Force and surpassed the Cedar Point coaster as the world's tallest complete-circuit coaster. It also set a record for longest track length - 8133 feet, 2 inches (2479 m), which it currently holds. Coaster Facts * Steel Dragon 2000 is the tallest coaster to utilize a traditional chain lift. Because of the length of the lift hill, two chains are used - one for the bottom half and one for the top half. A single chain would have been excessively long and heavy, at least twice the weight of one of the trains. As a result, two trains can safely occupy the lift simultaneously. * The building of Steel Dragon 2000 required far more steel than other coasters for earthquake protection. This put the cost of the coaster at over $50,000,000. * On August 23, 2003, Steel Dragon 2000 was involved in an accident during a run in which one of its trains lost a wheel. The coaster did not operate during the 2004 and 2005 park seasons. It reopened September 3, 2006.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as the type of steel, quality, quantity, and market conditions. It is best to contact suppliers or check market prices for the most accurate and up-to-date cost information.

- Q: My boyfriend says he has balls of steel.

- Easy to test. Put a magnet near them. If they attract, then they're made of steel. I'd be willing to bet I'd know what will happen, though! I know you can get metal hip replacements but .........

- Q: What does "steel roll number" mean?

- According to the project schedule, track and coil encoding management to the quality of the products, which makes the production with a rational and quality after processing, troubleshoot save time, contribute to the automation of production smoothly, improve and stabilize the quality of products for production order arrangement and classification of coils.

- Q: How are steel coils used in the marine industry?

- Steel coils are commonly used in the marine industry for various applications such as shipbuilding, offshore structures, and maritime equipment. These coils are used to manufacture components like hulls, decks, bulkheads, and other structural parts that require high strength and durability. Additionally, steel coils are also used in the production of marine machinery, pipelines, and storage tanks, ensuring the reliability and performance of vessels in harsh marine environments.

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Steel okorder /

- Q: How are steel coils coated to prevent rust and corrosion?

- Steel coils are coated to prevent rust and corrosion through a process called galvanization. This involves immersing the coils in a bath of molten zinc, which forms a protective layer on the steel surface. This zinc coating acts as a barrier, preventing oxygen and moisture from coming into contact with the steel, thus reducing the risk of rust and corrosion.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- Any okorder /

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with P r ime Quality and Lowest Price Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords