Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

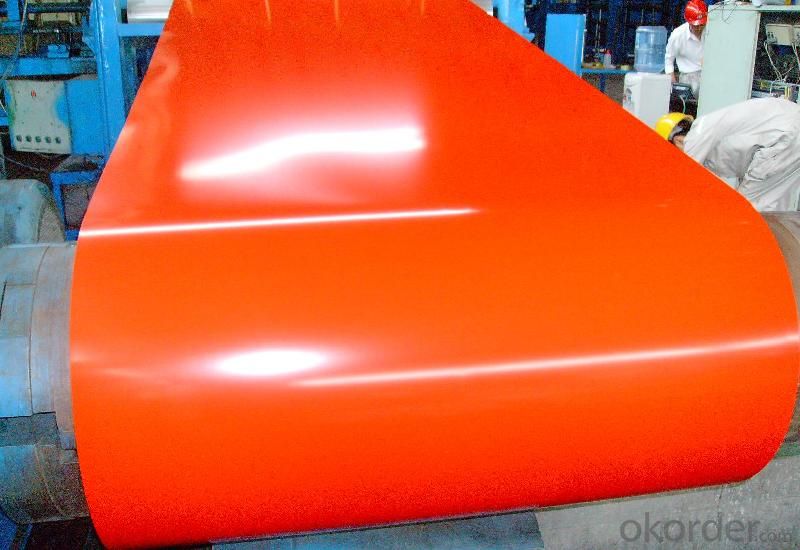

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: Has anyone painted their appliences with stainless steel paint? I found on the internet what is called Thomas Liquid stainless steel paint. If you have used it for your kitchen appliences or cabinets, how were the results? How hard was it to apply? Would you recommend it?

- I am also considering buying Thomas Liquid Steel, but have not used it or seen it used before. I did call a store that sells this product and they said they saw the mfg demo the product at a trade show. The store rep told me that the results were absolutely amazing. I think I will buy the medium kit direct from the mfg for $129 and give it a test run first on something other than my kitchen appliances.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Someone stated even the $99 walmart bikes are aluminum now. WRONG! Most Walmart bikes have steel frames unless you drop about $200.00. Personally, I prefer aluminum over steel. It's lighter, most times - just as strong and won't rust if you get a ding or scrape in the paint. See links below on Trek M/B. Trek 820 - steel frame - $329.99. Trek 3500 - aluminum frame - $359.99.

- Q: What are the dimensions of steel coils used in the metalworking tool industry?

- The metalworking tool industry has a wide range of dimensions for steel coils, which can vary depending on the specific application and requirements of the tool. However, there are certain dimensions that are commonly observed in this industry. Steel coils used in metalworking tools typically come in different widths, ranging from 24 inches to 72 inches. The thickness of the coils can also vary, with common thicknesses ranging from 0.020 inches to 0.250 inches. Moreover, the length of the coils can vary significantly, with standard lengths usually falling between 100 feet and 2000 feet or even more. These dimensions are selected based on several factors, such as the type of metal being worked, the specific tool being used, and the desired outcome of the metalworking process. Additionally, other factors like the weight and handling capabilities of the tool, as well as the efficiency of the manufacturing process, may also influence the dimensions of the steel coils used. To ensure the appropriate dimensions for steel coils in the metalworking tool industry, it is essential to consult with manufacturers, suppliers, or industry experts. This is crucial because these dimensions can vary based on specific needs and preferences.

- Q: What are the different types of steel coil storage locations?

- There are several types of steel coil storage locations, including outdoor yards, warehouses, racks, and shelves.

- Q: Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- Despite what Billy Goat says there are Crossbows that fire both Ball bearing and bolts. As for any chance of hitting your target living or paper with and degree of accuracy I doubt your chances. Especially small game. Stick to using quarrels/bolts!

- Q: What are the safety regulations for steel coil production facilities?

- The safety regulations for steel coil production facilities typically include measures such as proper training and certification for employees, regular equipment inspections and maintenance, use of personal protective equipment, implementation of fire prevention and evacuation plans, adherence to hazardous material handling protocols, and compliance with occupational health and safety standards. These regulations aim to minimize the risk of accidents, injuries, and environmental hazards within the facility.

- Q: Hi, I have ranch style home. I would like to remove a barring wall, And leave it open it will become a 18' foot 7 inch opening , and I'm interested in installing a steel beam so that i may remove the barring wall that supporting the ceiling and rafters. My house is about 57' feet long 28' feet 7 inch wide and it is 13' feet high from the floor to the top of the roof ridge. I heard there is aluminum beams but I never heard of that, I've only heard of steel beams. I don't want to use wood. I would also like to now how much longer do i need the beam to be the opening would be 18'7 plus the extra that i would need to put on the block wall to hold the beam up, do I make it 2' feet bigger so i can have a foot on each side that would sit on a block wall. or do i need more then that.THanks for your help

- My okorder for help

- Q: Explain your answers please. I was watching mythbusters and they bought a steel coffin over a wooden one because they thought it would hold more dirt. Now how come bridges that have been made of wood lasted way longer than steel bridges? Or rollercoasts for example.

- steel.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords