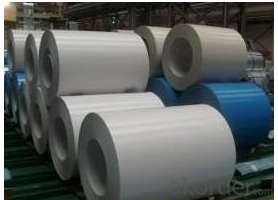

Pre-Painted Galvanized Steel Coil with Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Iron too heavy for Ulysses but if there was any iron used id imagine it was steel. Can steel go deeper into sun than iron? Compare two bolts.. 1steel 1iron..is there a difference to what the steel can do?

- Dont understand are you going to put them in sun ? Sun made from gas wich is on fire. Its impossible to get to the sun and not to get burn. Steel is really more solid and strong than iron so its more hard to break it or to bend. But in camparing of fusion temperature - iron is a bit more better, though it would not make a big difference .From metals - tungsten has the highest fusion temperature - near to 3400 C . Iron is near to 1530 C, steel is near to 1300 -1500 C. So according to this tungsten can go most close to sun. Right near the sun temperature is millions of degrees so anything will fuse and burn there.

- Q: What are the common defects in steel coils?

- During the manufacturing or handling processes of steel coils, several defects commonly occur. These defects have the potential to impact the quality and performance of the steel, making it crucial to identify and resolve them to ensure the production of top-notch steel products. Some of the typical defects found in steel coils are as follows: 1. Edge waves or buckles: This defect arises when the edges of the steel coil become wavy or buckled. It can be caused by improper winding, uneven cooling, or excessive tension during the manufacturing process. Edge waves can pose challenges in further processing and compromise the appearance of the final product. 2. Coil breaks: Coil breaks refer to longitudinal breaks or cracks that emerge in the steel coil due to excessive strain or stress. Improper winding, uneven cooling, or excessive tension during the manufacturing process can trigger these breaks. Coil breaks can negatively impact product quality and are a major concern within the steel industry. 3. Surface defects: Scratches, pits, or stains on the surface of steel coils are considered surface defects. These can occur due to improper handling, surface contamination, or inadequate cleaning processes. Surface defects can affect the steel's appearance and may also lead to corrosion or other performance issues. 4. Slivers: Slivers are thin strips or flakes that can peel off from the edges of the steel coil. Poor edge trimming, improper handling, or defects in the rolling mill can cause these slivers. Slivers can impede further processing and may also compromise the surface quality of the final product. 5. Weld defects: Weld defects can occur in steel coils that are made by welding multiple strips together. These defects can involve incomplete fusion, porosity, or cracks in the weld area. Weld defects can weaken the steel and impact its mechanical properties, rendering it unsuitable for certain applications. 6. Shape defects: Camber, coil set, or crossbow are examples of shape defects found in steel coils. These defects can be attributed to uneven cooling, improper winding, or tension variations during the manufacturing process. Shape defects can make processing the steel challenging and may result in dimensional inaccuracies in the final product. Manufacturers and users of steel coils must be aware of these common defects and take appropriate measures to prevent or mitigate them. Implementing quality control measures, following proper handling procedures, and conducting regular inspections can aid in identifying and rectifying these defects, ensuring the production and utilization of high-quality steel products.

- Q: What are the different types of steel processing equipment for coils?

- There are several types of steel processing equipment used for coils, including slitting lines, cut-to-length lines, blanking lines, and coil-to-coil lines. Slitting lines are used to slit wide steel coils into narrower strips, while cut-to-length lines are used to cut coils into specific lengths. Blanking lines are used to cut shapes out of coils, and coil-to-coil lines are used to transfer coils from one processing stage to another.

- Q: What are the different coil slitting methods used for steel coils?

- There are three main coil slitting methods used for steel coils: rotary shear slitting, loop slitting, and oscillating slitting. Rotary shear slitting involves using rotating knives to cut the steel coil into narrower strips. Loop slitting is a process where the coil is looped through a series of rolls, and the desired width is achieved by adjusting the tension in the loop. Oscillating slitting is another method where the steel coil is passed through a set of oscillating blades, resulting in precise and high-speed slitting. These methods offer various advantages and are chosen based on the specific requirements of the steel coil slitting process.

- Q: What are the common standards and specifications for steel coils?

- In the industry, there are various widely recognized and utilized standards and specifications for steel coils. Some notable ones include: 1. ASTM A36/A36M: This specification is concerned with carbon structural steel shapes, plates, and bars of structural quality. It is intended for use in constructions that involve riveting, bolting, or welding. 2. ASTM A572/A572M: This specification focuses on high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It is applicable for constructions involving bolting, riveting, or welding. 3. ASTM A653/A653M: This specification pertains to steel sheet that is zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) through the hot-dip process. 4. ASTM A1011/A1011M: This specification covers various types of steel sheet and strip in coils, such as hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet, also known as galvanized steel sheet, and strip. 6. EN 10111: This European standard outlines the requirements for continuously hot-rolled low carbon steel sheet and strip that are suitable for cold forming. 7. ISO 3575: This International Organization for Standardization standard lays down the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few instances of the prevalent standards and specifications employed for steel coils. It is crucial to note that different industries and applications may have specific demands, thus consulting the relevant standards and specifications for the particular application is always advisable.

- Q: I'm wondering if steel casings are bad for a 1911. I know that an AK-47 will eat up steel casings all day long, but steel casings are bad for, and can be hard on an AR-15. I only have brass for my AR and that will never change. I'm curious as to how a 1911 fairs with steel casings. Is it bad for the gun or does it not matter? I'm asking because steel cased rounds seem to be the only readily available ammo these days. Thanks

- steel casings go back to the early 1900's for 1911's. Most guns were always able to handle them and most of that has carried on. I would think glocks are a no no for steel for longevity but in the caribbean we have mainly steel casings and that's all we use. the 1911 is probably the most popular hand gun down there. I own one, and FM. Over 1000 rounds so far in her between me and my dad (previous owner)

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are specifically designed to provide a protective layer against wear and tear caused by friction, impact, or other forms of abrasion. Coating steel coils with abrasion-resistant materials helps to enhance their lifespan and durability, making them suitable for various applications that involve high levels of abrasion or mechanical stress.

- Q: Can steel coils be coated with light-reflective materials?

- Yes, steel coils can be coated with light-reflective materials.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as the primary material for producing pipes and tubing. These coils are processed and formed into various shapes and sizes to create the necessary components, such as the main exhaust pipe and smaller sections for mufflers and catalytic converters. The steel's strength and durability make it an ideal choice for withstanding the high temperatures and corrosive nature of exhaust gases, ensuring the longevity and functionality of the system.

- Q: I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- I'd say add Excadrill to the team. He's got pretty decent stats and a nice learnset. Otherwise Probopass works pretty well

Send your message to us

Pre-Painted Galvanized Steel Coil with Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords