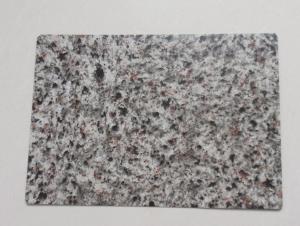

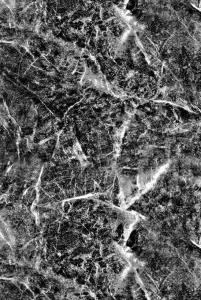

Pre-painted Galvanized Steel Coil-JIS G 3312-stone pattern9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: How do steel coils contribute to acoustic performance in buildings?

- Steel coils can contribute to acoustic performance in buildings by providing sound insulation and reducing noise transmission. When installed as part of a building's structure, steel coils can help absorb and dampen sound vibrations, preventing them from traveling through walls and floors. This can result in a quieter and more comfortable indoor environment, minimizing disruptions and enhancing overall acoustic quality within the building.

- Q: In construction, what types of stress require steel to be placed in footings?

- Steel is always added to concrete to handle local 'tension' stresses. (Sometimes to provide extra compression in 'pre-stressed' applications, but the steel is still in tension.) Steel would be added to the lower section of footings to stiffen them to 'bridge' local 'soft spots' in the substrate.

- Q: help me and my twin love this cutie in our form !? how do we steel hime from bitchey rebecca!? X X X xX

- Well i never had to steel a guy because if I have to go through all of that obviously hes not for me. Also, I never been that desperate. But if you can steel the boy your going to share him with your twin? thats not very... normal. Also if you can steel the guy, how long do you think hes going to stay with you before someone else takes him. Also you should read more so you can spell better because cute guys try to take advantage of dumb girls.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and oscillating slitting.

- Q: How are steel coils tested for flatness and straightness?

- Steel coils are tested for flatness and straightness using a variety of methods. One common method is to pass the coil through a series of rollers that apply pressure and measure any deviations in the surface. Another method involves using laser sensors to scan the entire coil and detect any irregularities. Additionally, visual inspections are conducted to identify any visible imperfections or distortions.

- Q: How are steel coils used in the construction industry?

- Steel coils are commonly used in the construction industry for various purposes such as manufacturing structural components, reinforcing concrete structures, and creating durable roofing and siding materials. These coils are unraveled and cut into specific sizes to meet the project requirements, ensuring strength, stability, and longevity in construction applications.

- Q: What is the role of steel coils in the construction industry?

- Steel coils play a crucial role in the construction industry as they are used for various purposes. They are primarily used in the fabrication of structural components such as beams, columns, and trusses, providing strength and stability to buildings. Steel coils are also utilized in the manufacturing of roofing and siding materials, reinforcing bars, and various mechanical components. Their versatility, durability, and resistance to corrosion make them an essential material in construction, ensuring the longevity and safety of structures.

- Q: y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- the grade of the sword is one aspect but there's more to it. the quality of the sword itself is a much more important factor a good quality 1045 grade blade can often be much better than a medium quality 1060 or 1095 blade. the quality of the work is much more important than the grade of the steel

- Q: How are steel coils used in the production of metal signage?

- Steel coils are an essential component in the production of metal signage. These coils are typically made from high-quality steel and come in various thicknesses and widths. The use of steel coils allows for efficient and cost-effective manufacturing processes. To begin, steel coils are unwound and fed into a machine called a roll former or a metal press. This machine shapes the steel into the desired form and design for the signage. The coils' ability to be easily manipulated and shaped makes them ideal for creating intricate and customized signage designs. Once the steel has been formed, it can undergo various processes to enhance its appearance and durability. For instance, the steel may be coated with a layer of paint or powder coating to protect it from corrosion and provide a visually appealing finish. This coating can also be customized to match specific branding or design requirements. After the steel has been shaped and coated, it can be further processed to add features such as embossing or perforations. These additional details can enhance the overall aesthetic appeal of the metal signage and make it stand out. Furthermore, steel coils offer excellent structural integrity, ensuring that the metal signage remains strong and durable even in harsh environmental conditions. This durability is particularly crucial for outdoor signage that needs to withstand exposure to weather elements such as rain, wind, and sunlight. In summary, steel coils play a vital role in the production of metal signage. Their versatility, durability, and ease of manipulation make them an ideal material for creating customized designs. Whether it's for indoor or outdoor use, steel coils provide the necessary strength and aesthetic appeal required for high-quality metal signage.

- Q: I have been wanting a new pair of hiking boots, but haven't had the money. I just got a job that requires me to have steel toed boots. The job is only for a few weeks, but I may be required to wear them on other jobs in the future. Regardless of which style I get, I will most likely be buying Red Wing boots. On their website, I see they have steel toed hiking boots. What is the purpose of a steel toed hiking boot? Why would a hiker need to have steel toed boots? Wouldn't that just be more weight? I see that some of their hiking boots have aluminum toes, claiming to be 33% lighter than steel with the same protection. Would these boots be good potential hiking boots as well as suitable for construction or should I just focus on work boots and buy myself some hiking boots at a later date?

- Steel toed boots is a safety factor thing. Wilderness workers ie lumber jacks need safety shoes as well. But for long distance hiking steel toed shoes would be impractical due to the weight and wear and tare on The trails and your body. Get the boots you need for work, get the hiking boots you want after the next paycheck.

Send your message to us

Pre-painted Galvanized Steel Coil-JIS G 3312-stone pattern9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords