Pre-painted Galvanized Sheet Coil with Good Quality in White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• good corrosion resistance

• perfect weather resistance

• decoration, molding, corrosion resistance

• Workability

• High strength

• Good formability

• Good visual effect

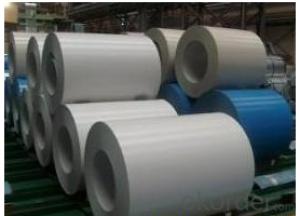

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q: What are the challenges in coil slitting for narrow strip widths?

- The challenges in coil slitting for narrow strip widths include maintaining consistent tension throughout the process, minimizing edge burrs and camber, preventing material damage or deformation, and ensuring accurate width measurements and tolerances. Additionally, handling and feeding thin strips can be more difficult, as they are more prone to wrinkling, telescoping, or jamming during the slitting operation. Overall, achieving precision and high-quality results in coil slitting for narrow strip widths requires advanced equipment, expertise, and careful attention to detail.

- Q: How are steel coils used in the production of steel wire?

- Steel coils are used in the production of steel wire by being unwound and fed into a wire drawing machine. The coils provide a continuous and consistent supply of steel, which is passed through a series of dies to reduce its diameter and increase its strength. This process is repeated multiple times until the desired wire diameter is achieved.

- Q: Can steel coils be painted?

- Yes, steel coils can be painted. Painting steel coils is a common practice to enhance their appearance, protect them from corrosion, and provide additional durability. The coils are typically cleaned, prepped, and coated with a primer before applying the desired paint color.

- Q: and also what makes different hardness of stainless steel?

- The person above me is right .The stainless steel is used in shaving blades

- Q: How do steel coils contribute to thermal insulation in buildings?

- Steel coils do not directly contribute to thermal insulation in buildings. Steel coils are typically used in the construction of structures and for various applications, but they do not have inherent thermal insulation properties. Other materials such as insulation boards, panels, or foams are commonly used for thermal insulation in buildings.

- Q: How do steel coils affect the quality of finished products?

- Steel coils can greatly impact the quality of finished products in various industries. One of the key ways steel coils affect product quality is through their dimensional accuracy and consistency. When the steel coils are not properly manufactured or have irregular dimensions, it can lead to issues in the production process and result in finished products that do not meet the desired specifications. Furthermore, the surface quality of steel coils is critical in determining the final appearance and performance of the finished products. Coils with surface defects, such as scratches, rust, or unevenness, can negatively impact the aesthetic appeal of the products, making them less desirable to customers. Moreover, these defects can also affect the functionality and durability of the finished products, leading to potential failures or reduced lifespan. The mechanical properties of steel coils also play a vital role in determining the quality of finished products. Coils with inconsistent or inadequate mechanical properties can compromise the strength, toughness, and overall performance of the end products. For example, in industries such as automotive or construction, where strength and reliability are crucial, the use of steel coils with the wrong mechanical properties can lead to safety hazards or structural failures. Additionally, the chemical composition of steel coils can significantly influence the quality of finished products. The presence of impurities or variations in the alloying elements can affect the material's corrosion resistance, weldability, and other essential properties. This, in turn, can impact the longevity and functionality of the final products. In summary, steel coils have a substantial impact on the quality of finished products. Their dimensional accuracy, surface quality, mechanical properties, and chemical composition all contribute to the overall performance, appearance, and durability of the end products. Therefore, it is crucial to ensure that steel coils used in manufacturing processes meet the desired standards to achieve high-quality finished products.

- Q: How are steel coils used in the production of automotive frames?

- Steel coils are used in the production of automotive frames by being unwound and fed into a machine that shapes and welds the steel into the desired frame structure. The high-strength and durability of steel make it an ideal material for automotive frames, providing structural integrity and safety to the vehicle.

- Q: Cooling bed generally a part of the steel rolling mills

- In the USA, a steel cooling bed is called a run-out table. It consists of a series of steel rolls. Each roll may be individually driven by an electric motor. DC motors are often used with parallel armatures connected to a common armature voltage control speed control unit. The roll speed is controlled to match the speed of the incoming sheet of steel so that the steel does not slide or skid on the surface of the rolls. Field trim resistors help to assure that the speed and torque of rolls is matched. A centering mechanism may be used to keep the steel in the center of the table. Water may be sprayed from the top and bottom to aid cooling. After an initial run out table, the strip of steel may be cut on-the-fly into individual sheets which pass to another table that is running slightly faster to separate the sheets. Alternatively, the steel may be coiled at the end of the table.

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they are shaped and formed into various components such as turbine blades, casings, and structural supports. The strength and durability of steel make it suitable for withstanding high temperatures and pressures, ensuring the reliability and longevity of the equipment. Additionally, steel coils are often used in the production of electrical transformers and generator cores, providing a magnetic circuit that efficiently converts mechanical energy into electrical energy.

Send your message to us

Pre-painted Galvanized Sheet Coil with Good Quality in White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords