Pre-Painted Galvanized Steel Sheet/Coil Best Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

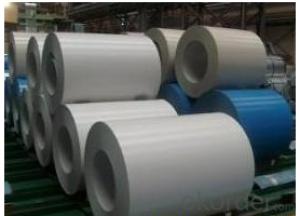

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of coil edge trimming machines?

- There are several different types of coil edge trimming machines available in the market. These machines are specifically designed to trim the edges of coils or rolls of various materials such as metal, paper, plastic, or fabric. Each type of machine has its own unique features and capabilities, catering to different trimming requirements. 1. Manual Edge Trimmers: These machines are operated manually, where an operator manually feeds the coil and trims the edges using a cutting tool or blade. Manual edge trimmers are typically used for low volume trimming applications and require the operator's skill and precision. 2. Semi-automatic Edge Trimmers: These machines have automated feeding mechanisms that assist in feeding the coil through the machine. The trimming process is still performed manually by the operator using a cutting tool, but the feeding mechanism reduces manual effort and increases productivity. 3. Automatic Edge Trimmers: These machines are fully automated and require minimal operator intervention. They are equipped with advanced sensors and controls that enable precise and consistent trimming of coil edges. Automatic edge trimmers can handle high volumes of coils and are often integrated into production lines for continuous trimming operations. 4. Rotary Blade Edge Trimmers: These machines utilize rotary blades to trim the edges of coils. The rotary blades rotate at high speeds, cutting through the material with precision. Rotary blade edge trimmers are commonly used for plastic or fabric coils, as they provide clean and smooth cuts. 5. Guillotine Edge Trimmers: These machines use a guillotine-like cutting mechanism to trim the edges of coils. The cutting blade moves vertically and cuts through the coil material in a straight line. Guillotine edge trimmers are suitable for trimming metal or paper coils, as they provide straight and accurate cuts. 6. Laser Edge Trimmers: These machines use laser technology to trim coil edges. The laser beam precisely cuts through the material, resulting in clean and precise edges. Laser edge trimmers are often used for delicate or high-value materials, as they minimize the risk of damage or distortion. Each type of coil edge trimming machine has its own advantages and limitations, and the choice of machine depends on the specific requirements of the application. Factors such as material type, coil dimensions, trimming precision, and production volume should be considered when selecting the appropriate machine.

- Q: How are steel coils used in the HVAC industry?

- Steel coils are commonly used in the HVAC industry for heat transfer purposes. They are typically used in air conditioning and refrigeration systems to transfer heat between the refrigerant and the surrounding air. The coils are designed to efficiently absorb or release thermal energy, allowing for effective cooling or heating.

- Q: I want to buy a chain that will last a long time and that i can wear ALL the time.What are the disadvantages to stainless steel jewelry?Does it look as good as silver?Is there much diference in apperance?

- I okorder /... Go for the stainless steel chain if you like it. It does look different than silver and has a more machine like metallic luster (I think). By the way, good stainless steel chains are often more expensive than silver. So don't let anyone laugh at you.

- Q: For the purpose of blade crafting. I need to heat treat this low quality steel i got.It's ASTM A36Is heat treatable and temperable?

- A36 is plain carbon structural steel. A36 could almost be considered junk steel. It is not suitable for cutting tools in any respect, as it is far to soft to hold an edge. A36 generally cannot be heat-treated, A36 can only be strengthened by cold-working, and even then, only up to about 60,000 psi. Heating the steel will only make it softer. The only real virtue of A36 is that it's easy to work with, it's easily cut and machined and it is very easy to weld. This is good for making steel structure, but not for knives. Probably the most popular material for knife blades is type 440C stainless. 440C is easy to work with in the un-treated state, and the heat treatment procedure is relatively simple.

- Q: .Yea, so I just saw the old Conan movie with Arnold. Good movie, but I still don't get it. What IS the riddle of steel???I get that like from the begining Conan's dad is like telling him a story about Crom and giants, and people got steel once Crom killef the giants. Then, later on in the movie Conan's talking to his lil' asian homie, and Conan tells him that when he dies... he'll go before Crom, and Crom will ask him what the riddle of steel is, and if he doesn't know it he'll get kicked out of barbarian heaven!But, what is the riddle of steel???C'mon guys... I want to in to barbarian heaven! LolBut, seriously though... what us it???.

- Riddle Of Steel

- Q: I noticed that Jimmy Page finger picked on a steel acoustic guitar on quite a few tracks like Stairway to heaven and other ones and I was wondering how did he do it? I know it is more difficult to finger pick on a steel acoustic because of the rougher steel strings and higher tensions so I was wondering do they make specific strings that allow for fingerstyle playing? Also Randy Rhoads finger picked a steel acoustic on Dee along with a Classical guitar.

- I've seen people put the guitar on a table and pick it that way. This is fairly common method in playing Bluegrass and country songs. There are finger picks that are used. These are finger rings with claws.

- Q: How are steel coils inspected for color consistency?

- To ensure that the final product meets the desired specifications, various methods are used to inspect the color consistency of steel coils. Visual inspection, which involves trained inspectors examining the coils under controlled lighting conditions, is one common method. By comparing the color of each coil to a standard color chart or a previously approved sample, any variations in color can be detected and noted for further analysis. In addition, objective color measurement can be achieved using advanced technologies such as spectrophotometers. These devices measure the reflective properties of the steel surface using light, allowing for precise color analysis. The obtained color data is then compared to the specified color range, and any deviations are flagged for further investigation. Furthermore, some manufacturers may opt for automated color measurement systems, such as colorimeters or color cameras, to inspect steel coils for color consistency. These systems provide quick and accurate assessments of the color of each coil, ensuring uniformity throughout the entire batch. Overall, the inspection process for color consistency in steel coils combines visual inspection, spectrophotometry, and automated color measurement systems. This comprehensive approach guarantees that the steel coils meet the required color standards, resulting in consistent and high-quality products for customers.

- Q: How are steel coils inspected for edge quality?

- Inspectors use a combination of visual inspection and non-destructive testing methods to assess the edge quality of steel coils. During visual inspection, trained inspectors carefully examine the entire length of the coils to detect visible defects like cracks, chips, or uneven edges. Non-destructive testing methods, including ultrasonic testing and magnetic particle inspection, are also utilized to uncover any hidden defects or imperfections in the edges of the steel coils. Ultrasonic testing employs high-frequency sound waves to identify internal flaws or discontinuities in the steel, while magnetic particle inspection utilizes magnetic fields and particles to detect surface or near-surface defects. Both visual inspection and non-destructive testing methods are vital in guaranteeing the quality of the steel coil edges. Manufacturers can identify and resolve any defects or imperfections by conducting these inspections, thereby ensuring that the coils meet the required quality standards.

- Q: How are steel coils cut to size?

- Steel coils are cut to size using a variety of methods such as shearing, slitting, or laser cutting. These processes involve using specialized machinery to ensure precise and accurate cuts according to the required dimensions.

- Q: I just started playing guitar last year. I never changed the chords. When my sister started taking guitar lessons her teacher said that she needed to change the chords. When i bought the guitar it came with steel strings but i bought nylon strings because they are easier on the fingers. The problem is i already tuned up the guitar but it sounds really bad like if it was not tuned. What can i do about this?

- Guitars okorder /

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil Best Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords