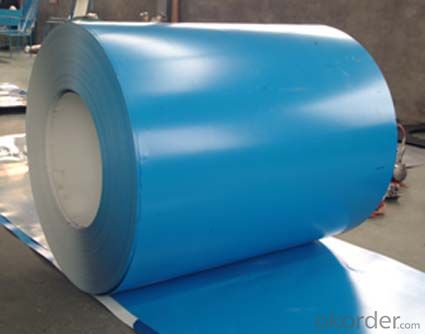

Pre-Painted Galvanized/Aluzinc Steel Sheet Coils Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color,

then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Excellent heat resistance performance

• High strength

• Workability, durability

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Model Number: coil

Type: Steel Coil

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

Width: 20-1250mm

Brand Name: KMRLON

color: blue color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: What are the different coil leveling methods used for steel coils?

- There are several coil leveling methods used for steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling involves passing the coil through a series of rollers to remove any curvature and create a flat surface. Stretcher leveling involves stretching the coil in different directions to remove any shape irregularities. Tension leveling applies tension to the coil during the leveling process to eliminate any residual stresses and create a uniformly flat product.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- * Yes, but I use both fine steel wool and Liquid Brasso Metal Polish on mine.* You can buy it at any Hardware and I believe Walmart carries it.* Great stuff.*

- Q: i know that steel helmets werent meant to stop bullets, but i was wondering do they have an value whatsoever for stopping bullets, or is that just yet another thing that hollywood made up(like the omaha beach scene in saving private rian)

- They are meant to protect from shrapnel and flying objects,or an enemy's hit to the head. Not meant for protection against bullets [we didn't think so] but at the right angle you could get lucky. What they are useful for is boiling water for coffee etc. Shaving taking a who/e's bath and in the field very handy to have. The bad thing about pots is wearing,you must get accustomed to the weight on your head and neck. You don't think you ever will but finally you do,and because it's many uses and you must wear it,you do!

- Q: I am currently writing a manuscript, and would like to know whether guns made out of steel, burn or melt when exposed to flames. Thanks.

- Steel guns would be very hard to melt, and impossible to burn, in any circumstances you could reasonably expect them to encounter at least. If you expose them to a flame they'll just get carbon on them from the flame, turning them black...

- Q: What are the different grades of steel used for coils?

- The different grades of steel used for coils vary depending on the intended application and specific requirements. Some common grades include low carbon steel (C1008/1010), medium carbon steel (C1035/1050), high carbon steel (C1074/1095), stainless steel (300 series), and advanced high-strength steel (AHSS) grades such as DP, TRIP, and TWIP. These grades offer varying levels of strength, ductility, corrosion resistance, and formability, allowing manufacturers to choose the most suitable grade for their specific coil processing needs.

- Q: How are steel coils used in the manufacturing of seat structures?

- Steel coils are used in the manufacturing of seat structures as they provide strength, durability, and stability to the seats. These coils are typically used in the construction of seat springs, which offer support and comfort to the occupants. The steel coils are carefully designed and placed within the seat structure to ensure proper weight distribution and to withstand the pressure exerted on the seats during usage.

- Q: For my homework we have to fill out a table, but I cannot find some basic uses of these types of steel anywhere:Low carbon steel (iron mixed with lt;0.25% carbon)High carbon steel (iron mixed with lt;1.5% carbon)Stainless steel (iron mixed with nickle an chromium)Titanium steel (iron mixed with titanium)Manganese steel (iron mixed with manganese) Thanks :)

- Low okorder / You say you cannot find there uses anywhere. These all came up using the simplest of web searches. You really need to have a word with your IT teacher as clearly you are not doing basic searches properly.

- Q: the comparison needed between other steel

- *Mild steel is ductile and can be easily machined. Generation of heat is less than that of steel machining.So, the tool can have better life and you can do more machining. Cost factor is of prime importance as other steel are more costly than Mild steel. Mild steel, a grade of steel that does not harden when heated and chilled with cold water, so further machining can be easy. Mild steel is easily available.You will find it in your scrape yard. No need to change the tool repeatedly and no special tools are required for machining. Above is the comparisation between alloy steel,SS and superalloys. Cutting speed and feed does not required special skills.

- Q: How are steel coils inspected for coil set using deflection measurement?

- Coil set, a condition where a steel coil exhibits a curvature along its length, is commonly inspected using deflection measurement techniques. These techniques involve applying force to the coil and measuring the resulting deviation from its original shape. To inspect for coil set, a steel coil is placed on a testing apparatus capable of applying controlled pressure. Typically, this apparatus consists of rollers or hydraulic cylinders that can exert force on the coil's surface. The first step in the inspection process involves securing the coil in place to ensure proper alignment and centering on the testing apparatus. Once the coil is positioned correctly, the apparatus applies a known force along its length. This force is consistently and controlledly applied to ensure accurate measurements. During the application of force, sensors or gauges positioned at specific points along the coil's length measure its deflection. These sensors can detect even minor deviations from the coil's original shape. The deflection measurements are recorded and analyzed to determine the severity of coil set. Typically, a set of predefined acceptance criteria is used to assess the coil's condition. If the recorded deflection measurements exceed these criteria, it indicates the presence of coil set. The severity of the coil set can be determined by comparing the actual deflection measurements with the acceptable range specified by the criteria. Deflection measurement is an effective method for inspecting steel coils for coil set since it provides quantitative data on the deviation from the original shape. This information enables manufacturers to identify and address any coil set issues, ensuring the quality of the steel coils before further processing or shipment to customers.

- Q: What are the trends and developments in the steel coil industry?

- Some of the current trends and developments in the steel coil industry include increased demand for high-strength and lightweight steel coils due to their use in various industries such as automotive and construction. Technological advancements have also led to the development of advanced coating methods, improving the durability and corrosion resistance of steel coils. Additionally, there is a growing focus on sustainability and environmental friendliness, leading to the use of recycled steel and the implementation of energy-efficient manufacturing processes in the industry.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Sheet Coils Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords