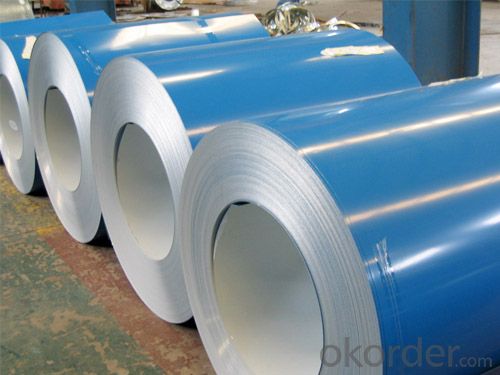

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality in Blue color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, blue color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common coil tests performed for quality control?

- The common coil tests performed for quality control include dimensional measurements, visual inspection for defects or damage, hardness testing, tensile strength testing, and surface finish evaluation.

- Q: How are steel coils used in the manufacturing of lighting fixtures?

- Steel coils are commonly used in the manufacturing of lighting fixtures as they provide a sturdy and durable framework for the fixtures. The coils are often shaped and welded to create the desired structure, ensuring that the lighting fixtures are robust and can withstand various installation environments. Additionally, steel coils can be coated or painted to enhance the aesthetics of the fixtures, making them more visually appealing.

- Q: What are the dimensions of steel coils used in the automotive industry?

- The dimensions of steel coils used in the automotive industry can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in the automotive industry range from 0.5mm to 3mm in thickness and from 500mm to 2000mm in width. The length of the coils can vary depending on the production process and customer specifications. Additionally, the weight of the coils can range from a few hundred kilograms to several tons. It is important to note that these dimensions are general guidelines and can vary depending on the specific needs of the automotive manufacturer.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: How are steel coils inspected for camber using laser profiling?

- Steel coils are inspected for camber using laser profiling, which is a non-contact measurement technique. Laser profiling involves the use of a laser beam that is emitted onto the surface of the steel coil. As the laser beam moves across the coil, it creates a profile of the coil's surface, capturing precise measurements. To inspect for camber, the laser profiling system scans the entire length and width of the coil, capturing data points at regular intervals. These data points are then analyzed to determine the deviation from a straight line, which indicates the presence of camber. During the inspection process, the laser profiling system compares the measured profile of the steel coil to a reference profile, which represents an ideal or straight surface. The deviation between the measured profile and the reference profile is calculated, and if this deviation exceeds a predetermined threshold, the coil is flagged as having camber. Laser profiling offers several advantages for inspecting steel coils for camber. Firstly, it provides a non-contact measurement, eliminating the need for physical contact with the coil and reducing the risk of damage. Additionally, laser profiling is highly accurate, capable of capturing even small deviations in the coil's surface. This ensures that camber is detected reliably, allowing for necessary corrective actions to be taken. Overall, the use of laser profiling for inspecting steel coils for camber ensures efficient and accurate detection of this defect, enabling manufacturers to maintain high-quality standards and deliver reliable products to customers.

- Q: How are steel coils processed for slitting or shearing?

- Steel coils are processed for slitting or shearing by first unwinding the coil and then passing it through a set of rotating circular blades. The blades cut the steel coil into narrower strips, which are then either rewound into smaller coils (slitting) or cut into individual sheets (shearing). This process allows for the production of various sizes and shapes of steel products for different applications.

- Q: What are the different types of steel coil cuts?

- There are several different types of steel coil cuts that are commonly used in various industries. These cuts are made during the steel manufacturing process to produce steel coils of different sizes and shapes, which can then be used for different applications. 1. Slit Coil: Slit coil is one of the most common types of steel coil cuts. In this process, a large steel coil is cut into narrower strips or slits. Slit coils are typically used for applications that require smaller widths, such as automotive parts, appliances, and construction materials. 2. Sheet Coil: Sheet coil is another type of steel coil cut that involves cutting a large coil into flat sheets. These sheets can be further processed to create different products, such as roofing materials, cladding, or fabrication components. 3. Blanked Coil: Blanking is a process in which a steel coil is cut into custom-shaped blanks. These blanks can be used for various purposes, such as forming into different parts, stamping, or machining. Blanked coils are commonly used in industries like automotive, aerospace, and manufacturing. 4. Precision Slit Coil: Precision slit coil is a specialized type of coil cut that involves cutting the steel coil with high precision and accuracy. This process ensures consistent width tolerances throughout the coil, making it suitable for applications that require precise dimensions, such as electrical components, precision tools, and automotive parts. 5. Oscillate Wound Coil: Oscillate wound coil is a unique type of steel coil cut that involves winding the steel strip in a zigzag pattern rather than a traditional flat coil. This method allows for tighter coil winding and can maximize the amount of steel on a coil. Oscillate wound coils are commonly used in industries that require high-volume production, such as stamping and roll forming. Overall, the different types of steel coil cuts cater to the specific needs of various industries, providing them with the flexibility to create products of different sizes, shapes, and dimensions.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Stainless Steel Water Can

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and polymer coating. Oiling involves applying a thin layer of oil to prevent corrosion and rust. Painting involves using a protective paint coating to provide a barrier against moisture and other corrosive elements. Galvanizing involves coating the steel coil with a layer of zinc to provide corrosion resistance. Polymer coating involves applying a protective polymer film to prevent corrosion and improve durability.

- Q: Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. They are used primarily for the construction of the ship's hull and other structural components due to their strength, durability, and ability to withstand harsh marine environments.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality in Blue color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords