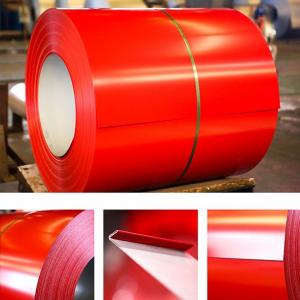

Color Coated Alu-zinc Steel Coil PPGP for building material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGCD1,SGCD2.SGCD3,SGC340, | Thickness: | 0.17-2.0mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | SGCC,SGCD1,SGCD2.SGCD3,SGC340, | |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | coil |

Packaging & Delivery

| Packaging Detail: | standard sea-worthy packaging or as buyers' requirement. |

| Delivery Detail: | Within 20-30 days after we receive depoist or L/C at sight |

color coated steel coil

Product Description

Company | CNBM |

Product | color coated steel coil |

Port | Shang Hai China |

Thickness | 0.17-2.0mm |

Width | 600-1250mm |

Material Grade | SGCC,SGCH,SGCD1-SGCD3,DX51D |

Technique | cold rolled |

Standard | ASTM,GB ,AISI,JIS,EN |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Application | Widely used for roofs, outer walls, ovens, explosive-proof steel, electrically controlled cabinets,galvanized tube/pipe, ceiling channel, building material |

Surface | coated |

Package | standard sea-worthy packaging or as buyers' requirement. |

MOQ | 20 tons |

Payment | L/C,T/T |

Delivery time | According to The Specifications And the Quantities,Time Begin When We confirm the Date of the Earnest or L/C. |

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- glass what

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- Depends what your gun is. I wouldn't shoot steel through a 5,000 dollar gun but my SKS jams up with anything except steel ammo. It adds wear to some guns but in most cases you won't shoot enough to cause any real problems. They also make steel that is coated in lacquer that protects your gun a little. In most cases steel is no big deal, in high performance weapons I would say no.

- Q: What are the different types of steel coil finishing machines?

- There exists a variety of steel coil finishing machines, each designed to accomplish specific tasks and attain desired outcomes. Some commonly encountered types are as follows: 1. Slitting Machines: These machines are employed to divide large steel coils into narrower strips of desired widths. They comprise a set of circular blades that cut through the coil as it progresses through the machine, resulting in multiple smaller coils or strips. 2. Cut-to-Length Machines: These machines are utilized to cut steel coils into specific lengths. They can be programmed to execute precise cuts at predetermined lengths, thereby ensuring accuracy and consistency. 3. Recoiling Machines: Recoiling machines are deployed to rewind steel coils into tightly wound, compact rolls. They are typically used to create smaller coils from larger ones or to recondition coils that have become loose or damaged. 4. Edging Machines: Edging machines serve the purpose of removing excess material from the edges of steel coils, thereby enhancing their overall appearance and ensuring uniform width throughout the coil. 5. Coating Machines: These machines are utilized to apply diverse coatings or finishes to the surface of steel coils, such as paint, galvanized coatings, or protective films. They often incorporate drying or curing systems to guarantee proper adhesion and durability of the applied coatings. 6. Packaging Machines: Packaging machines are employed to wrap or package steel coils for transportation or storage. They can envelop the coils in protective materials, such as plastic or paper, and secure them using strapping or other fastening methods. 7. Inspection Machines: These machines are used to scrutinize the quality and integrity of steel coils. They have the capability to detect defects, such as cracks, scratches, or surface irregularities, and provide feedback for the purpose of quality control. These examples merely scratch the surface of the diverse array of steel coil finishing machines available. Each machine serves a specific role in the steel coil finishing process, guaranteeing that the final product meets the desired specifications and quality standards.

- Q: What is stainless steel coil used for?

- Stainless steel coil is primarily used in various industries for its durability, corrosion resistance, and aesthetic appeal. One of the most common applications is in the manufacturing and construction sectors, where stainless steel coils are utilized to produce a wide range of products such as kitchen appliances, cutlery, automotive parts, and architectural structures. The corrosion-resistant properties of stainless steel make it an ideal choice for applications that require resistance to moisture, chemicals, and harsh environmental conditions. Additionally, the high strength and heat resistance of stainless steel coils make them suitable for use in industrial equipment, heat exchangers, and piping systems. Moreover, the aesthetic appeal of stainless steel, with its sleek and modern appearance, is often preferred in the design and production of consumer goods, including furniture, jewelry, and decorative items. Overall, stainless steel coil is a versatile material that finds extensive usage across various industries due to its excellent mechanical properties, resistance to corrosion, and aesthetic versatility.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several types of steel coil surface treatments for corrosion resistance, including galvanizing, zinc coating, chromating, and polymer coating.

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry. They are often utilized in the manufacturing and assembly of various aircraft components such as engines, frames, and landing gears. Steel coils provide strength, durability, and resistance to high temperatures, making them suitable for aerospace applications.

- Q: How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being compressed or wound into a helical shape, which provides the necessary flexibility and resistance to support various applications.

- Q: Can steel coils be coated with polymer?

- Yes, steel coils can be coated with polymer. The polymer coating provides protection against corrosion, improves durability, and enhances the appearance of the steel coils.

- Q: How are steel coils used in the manufacturing of industrial equipment?

- Steel coils are used in the manufacturing of industrial equipment as they serve as a primary raw material for fabricating various components such as frames, supports, and structural elements. These coils are often cut, shaped, and welded to create the desired parts and structures that provide strength, durability, and stability to the equipment. The steel coils ensure that the industrial equipment can withstand heavy loads, resist corrosion, and maintain structural integrity, making them vital in the manufacturing process.

- Q: I have a tiara and it oxidized and I'm not sure what material it is. I know it it isn't metal so i was wondering if is steel? Also if it's steel, can I do something to clean it?

- Yes - Steel can oxidize, its most commonly called rust Steel is a metal. Depending on the level of oxidation, you might be able to polish it with very fine steel wool. If is is really bad, then you might need a chemical cleaner such as Naval Jelly, which can be found at the hardware store. But the Naval Jelly might discolor the metal, so then you might need to polish it afterward to return its finish.

Send your message to us

Color Coated Alu-zinc Steel Coil PPGP for building material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords