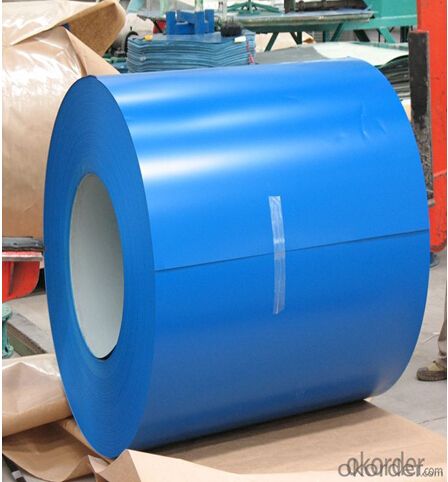

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Blue color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted GI/GL Steel Coil Images

4.Pre-painted GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- steel is a mixture of two or more metal or a metal with non metal to obtain both properties of the indivudual components. carbon steel for example.

- Q: How are steel coils used in the production of construction machinery?

- Steel coils are used in the production of construction machinery as they provide the raw material needed for manufacturing various components, such as frames, beams, and structural elements. These coils are processed and shaped into the desired forms, ensuring the machinery's durability, strength, and stability.

- Q: How are steel coils used in the production of conveyor systems?

- Steel coils are used in the production of conveyor systems as they are transformed into various components such as conveyor belts, rollers, and frames. These components provide the necessary strength, durability, and support required for efficient material handling and transportation in conveyor systems.

- Q: How are steel coils used in the manufacturing of pipes?

- Steel coils are used in the manufacturing of pipes by being uncoiled and fed into a pipe-making machine. The steel is then shaped and welded to form a continuous pipe, which is cut and shaped to the desired length and diameter.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: What are the different types of steel coil coatings for heat resistance?

- Heat resistance is achieved through the use of different types of steel coil coatings. These coatings are designed specifically to safeguard the steel surface, preventing it from deteriorating or oxidizing under high temperatures. Organic coatings, such as epoxy, polyester, or polyurethane, are commonly used. They form a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are typically employed in situations where moderate heat resistance is necessary. Another option is inorganic coatings, made from ceramic or metallic materials. These coatings offer excellent heat resistance and can endure extremely high temperatures. Industries like automotive, aerospace, and power generation frequently utilize inorganic coatings, as their components are exposed to intense heat. Specialized coatings are also available to meet specific heat resistance requirements. Silicone coatings, for instance, exhibit exceptional heat resistance and can withstand temperatures reaching 600°C (1112°F). They find common use in applications like exhaust systems, ovens, and industrial furnaces. Some steel coil coatings may also incorporate additives or fillers to enhance their heat resistance properties. These additions improve the coating's ability to withstand high temperatures and provide superior protection against heat-related issues. In conclusion, a range of steel coil coatings is available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application. Factors such as temperature range, duration of exposure, and environmental conditions must be taken into account when selecting the appropriate coating.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are used in the manufacturing of drivetrains as they are commonly used to create various components such as gears, shafts, and bearings. These coils are typically processed and shaped into the required forms through cutting, molding, and heat treatment. The steel's strength and durability make it ideal for withstanding the high stresses and forces experienced in drivetrain systems, ensuring reliable and long-lasting performance.

- Q: mass of steel ball=66.80 gramsdiameter of steel ball=2.51 cm

- Density Of A Ball

- Q: What are the different testing methods used for steel coils?

- There are several testing methods used for steel coils, including visual inspection, dimensional measurements, hardness testing, tensile testing, bend testing, and surface quality analysis. These methods help ensure the quality and compliance of steel coils with the specified standards and requirements.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Blue color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords