Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Best Selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

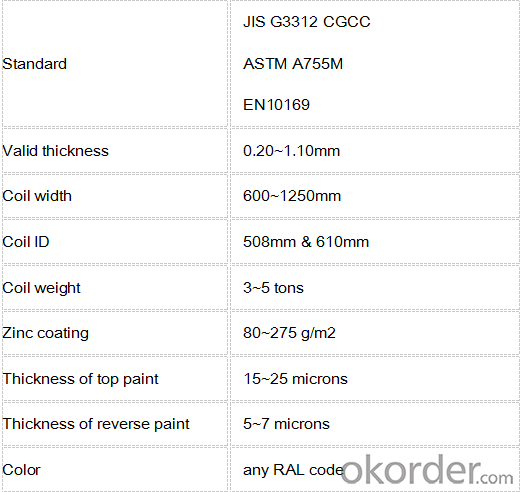

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil surface defects?

- There are several different types of steel coil surface defects, including scratches, pits, rust, scales, roller marks, oil stains, and dents.

- Q: What is stainless steel coil used for?

- Stainless steel coil is highly valued in numerous industries for its long-lasting nature, ability to resist corrosion, and attractive appearance. One of its most frequent uses occurs in the manufacturing and construction fields, where it is employed in the creation of a wide array of products such as kitchen appliances, cutlery, automotive components, and architectural structures. Its resistance to corrosion makes it especially suitable for applications that necessitate protection against moisture, chemicals, and harsh environmental conditions. Moreover, the strength and ability to withstand high temperatures make stainless steel coils well-suited for use in industrial equipment, heat exchangers, and piping systems. Furthermore, the sleek and contemporary look of stainless steel is often preferred in the design and production of consumer goods like furniture, jewelry, and decorative items. In summary, stainless steel coil is a versatile material that is extensively utilized in a variety of industries due to its exceptional mechanical properties, ability to resist corrosion, and its versatility in terms of appearance.

- Q: What are the different types of steel coil slitting methods?

- There are three main types of steel coil slitting methods: rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using a circular knife to cut the coil into smaller strips. Loop slitting involves creating a loop in the coil and then cutting it using a straight knife. Oscillating slitting involves using a reciprocating knife to make a back-and-forth motion while cutting the coil. These methods allow for precise and efficient slitting of steel coils into narrower strips.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- carbon will rust.. stainless doesn't rust unless it touches carbon so its definitely not stainless. Since its only 1.7% its extremely unlikely that it will rust unless you leave it outside for extreme long periods of time. Either way you should take care of it. Put it in the garage or something but you don't have to dry it after every use.

- Q: What are the different methods of protecting steel coils from corrosion?

- There are several methods for protecting steel coils from corrosion. One common method is applying a protective coating, such as zinc or epoxy, which acts as a barrier between the steel surface and corrosive elements. Another approach is using corrosion inhibitors, which are chemicals that can be added to the storage environment or applied directly to the steel to reduce the rate of corrosion. Additionally, proper storage conditions, such as controlling humidity levels and preventing exposure to moisture and chemicals, can also help protect steel coils from corrosion.

- Q: What are the common surface finishes for steel coils?

- There are several common surface finishes for steel coils, depending on the specific requirements and applications. Some of the most common surface finishes for steel coils include: 1. Hot-dip galvanized: This is a process where the steel coil is immersed in a bath of molten zinc, coating the surface with a protective layer. Hot-dip galvanizing provides excellent corrosion resistance and is commonly used in outdoor applications. 2. Electro-galvanized: In this process, a thin layer of zinc is electroplated onto the surface of the steel coil. Electro-galvanizing provides good corrosion resistance and a smooth finish, making it suitable for various applications, including automotive parts and appliances. 3. Galvannealed: Galvannealed steel coils are coated with a zinc-iron alloy by passing them through a high-temperature annealing process. This finish offers improved paint adhesion and excellent resistance to corrosion, making it suitable for manufacturing automotive parts and construction materials. 4. Tinplate: Tinplating involves coating the steel coil with a thin layer of tin, providing excellent corrosion resistance and a bright, shiny appearance. Tinplate is commonly used for packaging materials and cans. 5. Pre-painted: Pre-painted steel coils have a layer of paint applied to the surface, providing both corrosion resistance and an aesthetically pleasing finish. This finish is often used for building materials, such as roofing and siding. 6. Cold-rolled: Cold-rolled steel coils undergo a process where they are rolled at room temperature, resulting in a smooth, clean surface. Cold-rolled coils are typically used in applications where a high-quality surface finish is required, such as automotive parts and appliances. These are just a few of the common surface finishes for steel coils. The choice of finish depends on the desired properties, such as corrosion resistance, appearance, and specific application requirements.

- Q: Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses. Steel coils are not typically affected by low temperatures, as they are durable and resistant to cold weather conditions. However, it is important to ensure that the warehouse is dry and free from moisture, as prolonged exposure to dampness can cause rust and corrosion on the steel coils.

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- Bazza is heading in the right route yet time fogs the remember for us all. cut back small try samples off the inventory bar say pound coin thickness. warmth cherry purple and quick quench in water. The intense carbon metallic will be hardened so puzzling to scratch even as gentle scratches genuinely utilising a drill element or hacksaw blade. That warmth treatment will go away the metallic in its toughest maximum brittle state so will carry an edge yet snap like a carrot. So having hardened your merchandise it can be tempered to get rid of a few hardness and presented toughness. So the compromise is difficult adequate to carry the edge yet difficult adequate to deflect sensibly without fracture. Swot up on mood colors/warmth treatment and practice on scrap. an exciting litte exercising i have used with apprentices contained in the previous is to take an old document and anneal (melt) it so it drills or takes a said cut back genuinely then re harden it so it files back. The tang will be got here upon harder than the blade though it is the same metallic. note the tang will be bent without snapping. For practice you are able to harden the tang so it snaps common. in simple terms by how scrap chilly chisels, drill bits, files etc are in simple terms the metallic you want and recycleable by forging and warm temperature teatment. i think a Samurai second drawing close!!!!! sturdy success

- Q: what do we use steel for and whyand why do we use brass for instrumentsplz help its homework and i cant find the answer anywhere : (

- Brass and steel are type of metals that mostly use for moist area and also have luxury used cause of ability of shine .Steel definitely is for anti oxide ,mostly use in area that food and liquid such as acid ,milk ,soda,water are in contact .Brass most use for electric parts and decoration for ability of conductivity and shin .

- Q: I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- If okorder

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Best Selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords