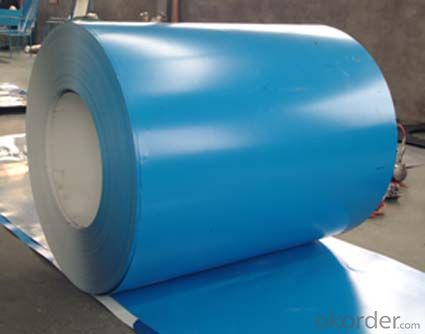

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

5.FAQ

1. What’s the application of this product?

surface sheet of balcony, frame of window, etc.

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after liquid dope with several layers of color

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• Superior workability

• Good visual effect

• Good capable of decoration

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- How to make it rust faster ? Adding oxygen to the water - bubbling air through it. Raising the temperature should make the reaction go faster, but I believe it also reduces the amount of dissolved gas. Adding salt, or an ionic compound like an acid, will accelerate electrochemical corrosion. That usually requires a less active metal, like copper, in contact with the steel, but variations in the composition of the steel may be sufficient to promote corrosion.

- Q: How are steel coils used in the automotive stamping industry?

- Steel coils are used in the automotive stamping industry to provide a continuous supply of flat steel sheets that are then fed into stamping machines. These coils are unrolled, straightened, and then fed through the stamping presses to create various automotive parts, such as body panels, chassis components, and other structural parts. The use of steel coils ensures efficiency, precision, and a consistent quality in the production of automotive parts.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: How are steel coils labeled and identified?

- To ensure accurate tracking and handling of steel coils throughout their journey, various methods are employed to label and identify them. The labeling and identification process typically consists of the following steps: 1. Initial Marking: At the outset, the manufacturer's name or logo is affixed to the steel coil, enabling easy identification of the producing company. 2. Unique Identification Number: A distinct identification number, commonly known as a coil number, is assigned to each steel coil. This number is often engraved or imprinted on the surface of the coil and serves the purpose of tracking and managing inventory. 3. Specifications of Size and Weight: Labels indicating the size and weight specifications of the steel coils are attached. This information aids in determining the coil's dimensions and weight capacity, ensuring appropriate handling and transportation arrangements. 4. Indication of Grade and Material: The labeling typically includes information about the grade and material composition of the steel coil. This essential data offers insights into the properties and quality of the steel, guaranteeing its correct utilization in manufacturing processes. 5. Heat or Lot Number: Steel coils may also bear a heat or lot number, which denotes the production batch from which the coil originated. This information contributes to traceability and quality control, simplifying identification in the event of any issues or defects. 6. Barcodes or QR Codes: Many steel coils now feature barcodes or QR codes that can be scanned using automated systems. These codes contain all pertinent information about the coil, streamlining data capture and management throughout the supply chain. Proper labeling and identification of steel coils are of utmost importance for efficient logistics management, inventory control, and quality assurance. By implementing these identification methods, manufacturers, distributors, and end-users can effortlessly track, handle, and utilize steel coils in a secure and productive manner.

- Q: Can steel coils be coated with tin?

- Yes, steel coils can be coated with tin.

- Q: When I took guitar lessons, I found that the Nylon strings are easier for me, but I love the sound of steel strings. Now, I have my own acoustic guitar, and 2 strings broke off, so I'm getting strings today. I'm not sure if Nylon strings would 'fit' on my guitar, and it's to soft of a noise. But the steel are much better sounding, but it's a little bit harder to push the string down on the fret. Which do you prefer, why?(:

- If your acoustic guitar is a steel-string (acoustic only means it's not electric) you can only put steel strings on it. Nylon strings would probably require modification of the nut and would sound terrible even then. A steel-string guitar is built and braced to work with steel strings and will not respond properly to the lighter tension of nylon strings. On the other hand, steel strings will destroy a guitar that is built for nylon in very short order. There are two things you can do here. If you have a steel-string guitar and are still using the strings that came on it, they are probably light gauge. You could try an extra-light set or even silk steel. Alternatively, you could have your guitar looked at by a guitar tech or other knowledgeable person and see if it needs a setup. The action (string height off the fretboard) on a properly adjusted steel-string guitar should actually be lower than on a classical guitar. Cheap guitars off the internet or from non-music stores are especially notorious for being poorly adjusted.

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- i would choose dark because it has alot more speed and power steel focuses more on defense a good team would be something like Umbreon Honchcrow Shiftry Spiritomb mightyena Sharpedo

- Q: What are the main factors that affect the strength of steel coils?

- The main factors that affect the strength of steel coils include the quality and composition of the steel used, the manufacturing process, the thickness and width of the coils, and any heat treatment or tempering applied to the steel. Additionally, factors such as storage conditions, handling, and transportation can also impact the strength of steel coils.

- Q: Why is it usually scorned by the shooting community to use steel cased ammo (like Wolf)? Always hear corrosive and steel is bad for the extractor/firing pin. Hulp a simpleton out!

- I okorder /

- Q: How are steel coils used in the manufacturing of wind turbines?

- Steel coils are used in the manufacturing of wind turbines to create the main structural components, such as the tower and the nacelle. These coils are shaped and welded to form the strong and durable framework that supports the turbine's blades and houses the generator. Additionally, steel coils are also used to fabricate other essential parts, such as the hub and the base, ensuring the stability and efficiency of the wind turbine.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords