Pre-painted Aluzinc Steel Coil Used for Industry for the Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

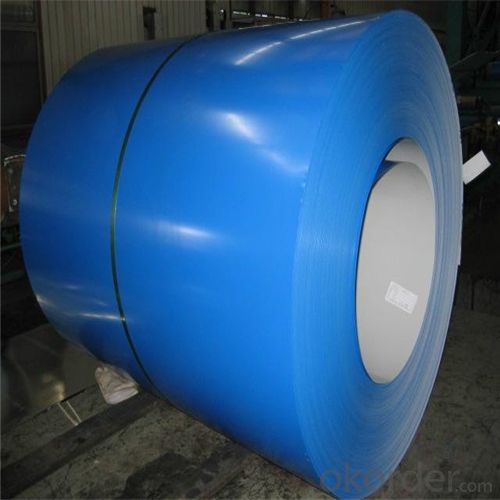

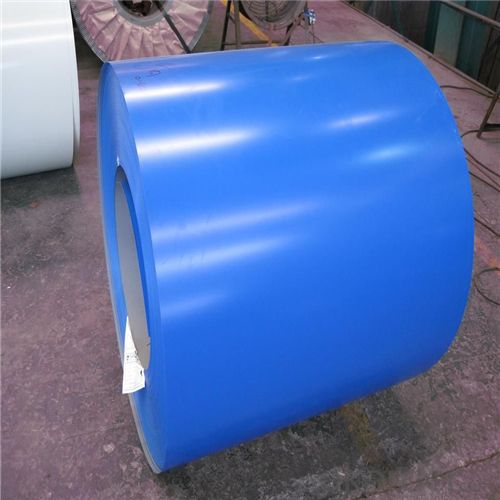

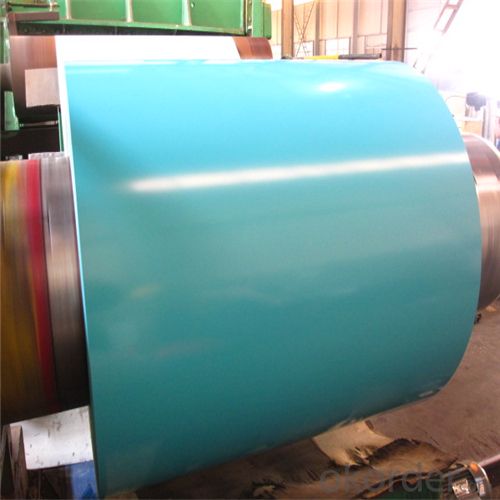

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different methods of coil rewinding for steel coils?

- Coil rewinding for steel coils can be approached in various ways, each with its own merits and considerations. One frequently employed technique is the slitting and rewinding process. This entails slicing the original steel coil into narrower strips, commonly known as "slits," and then winding these slits onto separate reels. Slitting and rewinding grants the ability to customize the width of the coil, making it popular in industries like automotive, construction, and packaging. Another method is oscillate winding. This approach involves rewinding the steel coil in a back-and-forth manner, resulting in a tighter and more compact coil. Oscillate winding proves particularly advantageous in reducing coil deformation during transportation and storage, as well as optimizing material usage. Additionally, the pancake coil winding method finds frequent use for steel coils. This technique involves rewinding the steel coil in a flat, pancake-like shape, making it easier to process and handle. Pancake coils are often employed in applications where space is limited, such as electrical transformers. Furthermore, advanced coil rewinding methods make use of automated equipment, such as robotic systems or computer-controlled winding machines. These technologies ensure precise and consistent rewinding, minimizing human error and enhancing overall efficiency. Ultimately, the choice of coil rewinding method hinges on the specific requirements of the application, including coil dimensions, material properties, and desired production output. Manufacturers must thoughtfully consider factors like coil quality, cost-effectiveness, and equipment capabilities when deciding on the most suitable method for their steel coil rewinding process.

- Q: Procedures for sharpening a knife with the stone and the steel?

- hi dude, its tough to seek for out intense-high quality steel as a thank you to maintain an side. maximum modern knives are ineffective, It relies upon on what style of side you pick. For the longest sharp side you want to might desire to attain a slowly graded v shape via fashioning the two side with equivalent strokes. The sharpest is a razor or twine side, based if left or appropriate surpassed, get a record and stroke up an down one side in basic terms, to create the burred side then on the choice element your end strokes circulate in direction of the element suited. this might create the sharpest decrease in one direction (left to superb far off from you and a lot of others) Theres some good diamond sprucing stones approximately. decrease than no circumstances use a blade to cut back tomato or distinctive fruit, the acids blunt the blade. Use a serrated side.

- Q: How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through various methods such as applying protective coatings, using edge protectors, securely packaging them with appropriate materials, and ensuring careful handling during transportation and storage.

- Q: Maybe it is obvious. But i have thought alot about it.I thought steel at a cool temperature was unbreakable. I am not one for science or physics or engineering (i am a political science major). But i don't understand why the planes that struck the world trade center on 9-11 didn't just dent the side and fall,How did the place break the steel? Was it the velocity? Is steel easily broken?I realized that i wasn't taught how the planes broke the steel, and that no one ever asked. I searched the web and i couldn't find the answer or even anyone who had asked the question before.(i don't care about conspiracy theories, i just want scientific facts)

- The buildings only had steel cores within the infrastructure to support the weight and flexibility - quite normal. You would be right if the whole surface of the building was pure reinforced steel with no openings (i.e. a ridiculous giant 100% purely steel tower). Can you imagine the force of a large jet at very high speed hitting a building, along with carrying vast amounts of highly explosive fuel. You don't need to, you've seen it... The bits of steel may well have been undamaged and collectable at ground zero, while the building was destroyed.

- Q: Are steel or graphite clubs better?

- I use steel shaft golf clubs (mens so called clubs) I find the garphite shaft that is typically used for womens clubs is too light and I have a messy swing Callaway Big Bertha is GREAT .... very forgiving club and the oversized clubhead is great for beginners up to advanced. *****FOR MEN - STEEL******* no graphite (just the woods have graphite shafts but the irons are steel

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- Yes, most definitely. Just make sure it's full and don't have air inside lol. You can tell it's full by it being heavy. I've seen bullet tests on TV and I'm like 100% positive it's gonna withstand. But no, you can't use it as bullet-proof vest, because it's HEAVY!! You can see on Youtube. 1 inch legitimate steel would stop even a 50 cal

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers by being cut, shaped, and welded together to form the structural components of the towers. The coils provide a strong and durable material that can withstand the weight and stress of the tower, ensuring its stability and longevity.

- Q: What is the standard weight of steel coils?

- The standard weight of steel coils can vary depending on the specific type and dimensions of the coil. However, in general, steel coils typically range in weight from a few hundred kilograms to several metric tons. The weight of a steel coil is primarily determined by its thickness, width, and length. Various industry standards and specifications exist to guide the manufacturing and trading of steel coils, which also include guidelines for determining the appropriate weight range for specific coil sizes.

- Q: Where can I find a great deal online for Danesco Stainless Steel Egg Poacher

- Shopping details: Danesco Stainless Steel Egg Poacher $34.99 Availability: Usually ships in 24 hours This item is available online, but is not available in stores. Prices, promotions, styles and availability may vary by store and online. Description/Features: Always Have the Right Tool for the Job with this Egg Cup by Danesco Made of Stainless Steel Easy to Clean Dimensions: 15.0 X 3.5 X 9.0 Estimated Ship Dimensions : 9 inches length x 15.5 inches width x 2.5 inches height Estimated Ship Weight: 2.40 pounds. We regret that this item cannot be shipped to PO Boxes.

- Q: Steel being my favorite type, I just picked up Heart Gold today, my gf got Soul Silver...I was wondering which steel types are available and somewhat easily obtainable in HG (and/or what is the earliest steel type I can get?)

- There aren't many Steel types in the Johto and Kanto regions. You'll have to rely on trading from Sinnoh and Hoenn to get most of the Steel types. In Soul Silver you can get a Skarmory on Rt 43, I believe. Ask your gf to catch you one when she gets there.

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry for the Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords