Pre-painted Aluzinc Steel Coil Used for Industry with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

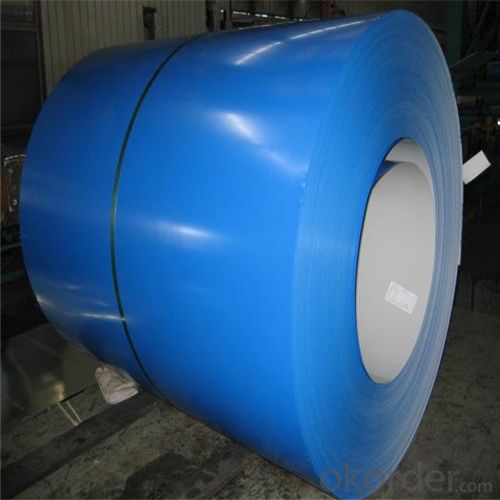

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

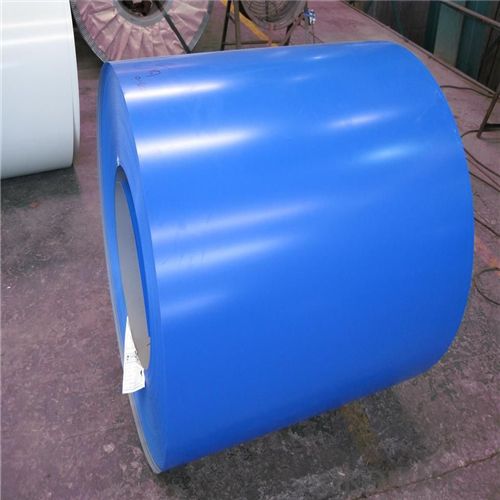

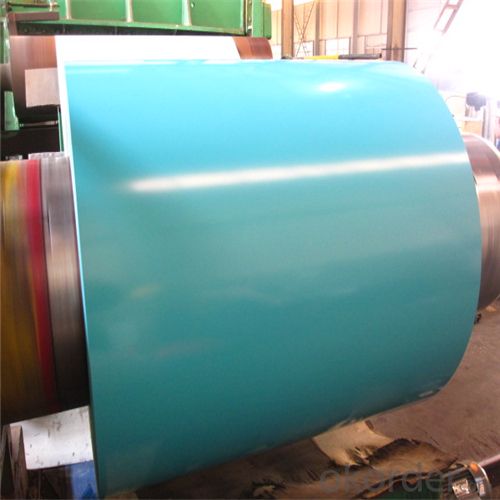

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the main factors that affect the formability of steel coils?

- The main factors that affect the formability of steel coils include the steel's composition, mechanical properties, thickness, temperature, and lubrication.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- Wouldn't it be easier to stick your coke in the freezer?

- Q: What are the different types of steel finishes available for coils?

- There are several types of steel finishes available for coils, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q: How do steel coils contribute to the automotive industry?

- Steel coils play a significant role in the automotive industry by contributing to the manufacturing of various components and structures in vehicles. These coils are made from high-quality steel and undergo a series of processes, including hot rolling, cold rolling, and annealing, to achieve the desired properties. One of the primary uses of steel coils in the automotive industry is in the production of body panels and frames. The high strength and durability of steel make it an ideal material for these applications, providing structural integrity and protection to the vehicle. Steel coils are transformed into sheets through a stamping process, allowing manufacturers to create complex shapes and designs for different vehicle models. Moreover, steel coils are also used in the production of suspension systems, including springs and shock absorbers. The elasticity and resilience of steel allow these components to withstand the constant impact and weight of the vehicle, ensuring optimal performance and comfort for the driver and passengers. Additionally, steel coils are utilized in the manufacturing of engine components, such as crankshafts, camshafts, and cylinder heads. These components require the strength and thermal resistance that steel provides, ensuring the efficient operation and longevity of the engine. Furthermore, steel coils are crucial in the production of exhaust systems, which play a vital role in reducing emissions and noise levels. Steel's resistance to heat and corrosion make it an ideal material for exhaust pipes, mufflers, and catalytic converters, ensuring their durability and functionality. Overall, steel coils are indispensable in the automotive industry as they contribute to the production of various components and structures that are essential for the performance, safety, and longevity of vehicles. The high strength, durability, and versatility of steel make it a preferred material choice, enabling manufacturers to create reliable and efficient automobiles.

- Q: How are steel coils processed for further use?

- Steel coils are typically processed for further use through a series of steps. First, the coils are uncoiled and fed into a machine that straightens and levels them. Then, the steel is cut into the desired length and width. Next, the edges are trimmed and any defects are removed. The coils are then cleaned, treated, and coated to enhance their corrosion resistance and appearance. Finally, the processed coils are either stored or transported to manufacturers who transform them into various products such as automotive parts, appliances, construction materials, and more.

- Q: What are the different methods of coil end welding for steel coils?

- Steel coils can be welded together using various methods. Some of these methods include: 1. Resistance Welding: By applying an electric current to the coil ends, the heat causes them to melt and join. This method is popular for its efficiency and speed. 2. Laser Welding: A high-energy laser beam is used to melt and fuse the coil ends precisely. This technique ensures high-quality welds. 3. Tungsten Inert Gas (TIG) Welding: TIG welding creates a protective atmosphere around the welding area using a non-consumable tungsten electrode and an inert gas like argon. It produces clean and strong welds, making it suitable for steel coil end welding. 4. Plasma Arc Welding: This method involves using a plasma torch to create an electric arc between the electrode and the workpiece. The intense heat generated melts the coil ends for welding. 5. Electron Beam Welding: A high-velocity beam of electrons heats and melts the coil ends. This technique is used for thick steel coils and offers deep penetration and high welding speed. 6. Friction Stir Welding: By using a rotating tool to generate friction and heat, the coil ends soften and fuse together. Although commonly used for joining aluminum coils, it can also be applied to steel coils. These are just a few examples of the different methods available for welding steel coil ends. The choice of method depends on factors such as desired weld quality, production speed, material thickness, and application requirements.

- Q: How are steel coils inspected for flatness?

- To ensure they meet the necessary standards, steel coils undergo a variety of methods and techniques to inspect their flatness. Trained inspectors visually examine the coil's surface for signs of waviness or unevenness, searching for visible defects like waves, buckles, or twists that could impact its flatness. Another approach involves using specialized equipment such as flatness gauges or profilometers to inspect the coil's flatness. These instruments measure the surface profile and provide detailed information about any deviations from the desired flatness. They can detect both local and overall flatness issues, offering a more precise assessment of the coil's quality. In addition to visual and instrumental inspections, physical tests can also be conducted to evaluate the flatness of steel coils. The "drape" test, for instance, involves draping the coil over a flat surface and measuring any noticeable gaps or unevenness. This test quickly identifies major flatness problems. Moreover, computerized analysis and simulation techniques are gaining popularity for inspecting the flatness of steel coils. These methods utilize advanced software to analyze the coil's surface data and generate comprehensive reports on its flatness characteristics. By comparing the actual surface profile with the desired specifications, these techniques provide a thorough assessment of the coil's flatness. Overall, the inspection of steel coils for flatness combines visual inspection, specialized equipment, physical tests, and advanced analysis techniques. These methods ensure that the coils meet the necessary flatness standards, which is essential for their successful application in industries such as automotive, construction, and manufacturing.

- Q: How do steel coils contribute to the sustainability of construction projects?

- Steel coils contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable and long-lasting material. Steel coils are manufactured to withstand extreme weather conditions, corrosion, and other external factors, making them ideal for construction projects that require strength and longevity. This durability reduces the need for frequent repairs and replacements, thus minimizing waste and resource consumption over time. Additionally, steel coils are recyclable. At the end of their lifespan in a construction project, steel coils can be easily and efficiently recycled. This process requires less energy compared to the production of new steel, resulting in reduced carbon emissions and environmental impact. Moreover, the recycled steel can be used in various industries, including construction, further promoting sustainability and resource conservation. Furthermore, steel coils contribute to the sustainability of construction projects by offering design flexibility. Steel is a versatile material that can be easily shaped, cut, and molded into different forms and sizes. This allows for efficient construction practices, reducing material wastage and optimizing resource utilization. Additionally, the lightweight nature of steel coils allows for ease of transportation and installation, further reducing fuel consumption and associated greenhouse gas emissions. Lastly, steel coils contribute to the sustainability of construction projects through their energy efficiency. Steel is an excellent conductor of heat and electricity, making it ideal for energy-efficient buildings. Steel coils can be used in the construction of walls, roofs, and other components that help to insulate buildings and reduce energy consumption for heating and cooling. This results in lower energy bills for the occupants and reduces the overall carbon footprint of the construction project. In conclusion, steel coils contribute to the sustainability of construction projects through their durability, recyclability, design flexibility, and energy efficiency. By using steel coils, construction projects can reduce waste, conserve resources, minimize environmental impact, and optimize energy consumption, thus promoting a more sustainable and environmentally friendly approach to construction.

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- High carbon steel is much harder than iron. In fact, steel -is- iron with carbon in it. Mild steel has a very low carbon content and is much softer. High carbon steel is much stronger after heat treatment. However, about 2% carbon, it is considered cast iron. Mild steel contains about 0.16% to 0.29% carbon content. It has a relatively low strength but is highly malleable.

- Q: Can steel coils be used in outdoor applications?

- Yes, steel coils can be used in outdoor applications. Steel is known for its durability and resistance to harsh environmental conditions, making it suitable for outdoor use. Additionally, steel coils are often coated or treated to further enhance their corrosion resistance, making them well-suited for various outdoor applications such as construction, automotive, and manufacturing industries.

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords