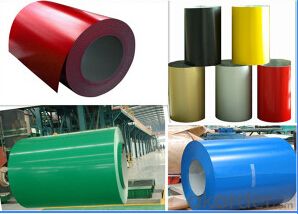

Coated Steel, PPGI / Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:AISI, ASTM, BS, DIN, GB, JIS

Surface Treatment:Coated

Certification:ISO, SGS, BV, Ciq,Bsj

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Constructions,Household Appliances,Roofing,etc.

Edge:Slit edge

Stock:Stock

Steel Grade:SPCC/SGCC/Dx51d/Dx52D

Commodity Name:Prepainted Galvanized Steel Coil

Grade:SPCC/SGCC/Dx51d/Dx52D

Thickness:0.16 to 1.00 Mm

Width:600 to 1500 Mm

Zinc Coating:Z 40-275 GSM

Colors:as Per Ral Shades/Customer Requirements.

Color Coating:Top 27+5um Back: 5-7um

Unit Weight:3-10 Ton

MOQ:25mt

Export Markets:Global

Additional Info.

Packing:Seaworthy Pacakge

Standard:SGS, BV, CIQ, BSJ

Origin:China

Production Capacity:5000 Tons Per Month

Product Description

Product Description

CONTENTS | PRODUCT SPECIFICATION | |||||

| Commodity | Prepainted galvanized steel coil | |||||

| Base Metal | Cold rolled, Electro-galvanized base metal, Hot-dip zinc coated base metal, Hot dip Al-Zn steel sheet | |||||

Thickness | 0.16 TO 1.00 mm | |||||

| Width | 600 TO 1500 mm | |||||

| Coil ID | 508 / 610 mm | |||||

| Type | coil/sheet/strips | |||||

Delivery Time | 15-30days after we receive deposit | |||||

Substrate Hardness | Soft, medium,full hard | |||||

| Zinc Coating | Z 40-275 gsm, AZ 40-180 gsm or as customer requirements | |||||

| Types of top coating | PE, Silicon modified polyesters, High-durability polyester, polyvinylidene fluoride | |||||

Colours | As per RAL shades/customer requirements. | |||||

| Surface Finishes | Glossy and Matte | |||||

| Price: | US $600-800 / Metric Ton | |||||

| Slits | 37mm and above | |||||

| Standards | AISI, ASTM, BS, DIN, GB, JIS | |||||

| Transport | By bulk or container | |||||

| Packing | Standard packing or at buyer's requirement | |||||

Applications:

Pre-painted steel metal products are used in a vast array of applications including:

construction industry

household appliances

automotive

industrial applications

packaging

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron is a natural ore. Google: Iron ore, click on Mineral Information Institute - Iron Ore. Steel is a man-made material, consisting of iron. Google: Sir Henry Bessemer, inventor.

- Q: I want to get a new knife but i cant decide if i wan a spyderco pacific salt or a cold steel ak47

- Given okorder / but always shop around and try Ebay...

- Q: pros and cons of stainless steel and carbon steel swords

- Well generally Stainless steel blades are machine made and are of a display quality.. so expect looks, but don't expect quality or functionality from one. From carbon steel, I'd say you'd be looking at swords for practitioners of a sword art, reenactment, and collector quality blades. Stainless Steel Pros: Good for short blades like kitchen knives, cheap, won't easily rust or corrode. Cons: Long blades like swords become increasingly brittle and can snap with light use, most lack actual tangs(part of the blade that keeps the blade in the handle.) and are just welded onto a wire that[if broken} will send the blade out like a missile when swung, these are cheap display quality only. Carbon Steel Pros: Are usually much stronger and of a higher quality than their stainless counterparts, are often handmade by professional sword-smiths, no two blades are alike, fully functional work of art. Cons: Requires responsible care and maintenance, will corrode and rust easier, can be much more expensive.

- Q: How are steel coils inspected for thickness and width accuracy?

- Steel coils are inspected for thickness and width accuracy using various methods. One common method is using non-contact laser or ultrasonic sensors that scan the surface of the coil to measure its thickness and width. These sensors provide accurate measurements without physically touching the coil. Additionally, manual measurements can be taken using calipers or micrometers to verify the accuracy of the coil's dimensions. Overall, a combination of non-contact sensors and manual measurements ensure that steel coils meet the required thickness and width specifications.

- Q: What are the different types of welding methods used for steel coils?

- There are several different types of welding methods used for steel coils, including gas metal arc welding (GMAW), flux-cored arc welding (FCAW), shielded metal arc welding (SMAW), and submerged arc welding (SAW). Each method has its own advantages and is used based on the specific requirements of the project.

- Q: I have a steel support beam can you remove one of the poles . the steel beam set on sender blocks on both side of the foundation. I have three steel beams support beam across the basement,I just want to remove one pole, can that be done.

- i would say no. it sounds like it is a baring wall. so if you take out one pole it is going to weaken the entire house.

- Q: What are the dimensions of steel coils used in bridge construction?

- The dimensions of steel coils used in bridge construction can vary depending on the specific requirements of the bridge project. However, generally speaking, the dimensions of steel coils used in bridge construction typically range from 0.5 inches to 1 inch in thickness and 36 inches to 72 inches in width. The length of the coils can vary as well, but is commonly around 20 to 40 feet. These dimensions allow for the fabrication of various structural components such as beams, columns, and plates that are essential for the construction of bridges. It is important to note that the dimensions may vary based on the specific design and engineering specifications of the bridge project, as well as the type and load capacity of the bridge being constructed.

- Q: Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. They are used primarily for the construction of the ship's hull and other structural components due to their strength, durability, and ability to withstand harsh marine environments.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils vary widely depending on the specific type and purpose of the coil. Generally, steel coils can range anywhere from a few hundred pounds to several tons in weight.

- Q: i have a pocket knife that is stainless steel that my mom found in the parking lot and i am wondering if oxygen peroxide will rust it? and if it dose is there something else i can use to get rid of the rust?

- Stainless does rust over time (EVERYTHING rusts it's called oxidation) Whenever something comes in contact with oxygen, the molecules will bond with the oxygen to form an oxide. Iron form iron oxide or rust which is reddish brown, apples turn brown after several minutes after it's been bitten. It all depends on the type of material used to manufacture the stainless. Stainless is made up of .2%-2% carbon, 11%%-28.5% chromium and iron. Some stainless is further advanced by adding other metals like nickel, molybdenum or niobium. Most stainless pocket knives are either normal steel coated with stainless or a cheaper form of stainless (it will have a high 300 number or very low 400 stamped on it). Other time, stainless will rust when a form of iron scratches the surface and contaminates the stainless, this is easily treatable if you get it quickly. Oxygen peroxide should not rust it, since the oxygen has already bonded with each other to form peroxide (2 oxygen molecules). It's the simplest form, but not the most stable (which means it could make your knife rust further). But I recommend steel wool or a scratch pad used to clean cook where (usually green or brown) to remove the rust.

Send your message to us

Coated Steel, PPGI / Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords