color coated sheets and coils of bright color/ppgi coils/cold steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

color coated sheets and coils of bright color/ppgi coils/cold steel coils

1. Application of color coated sheets and coils of bright color/ppgi coils/cold steel coils

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

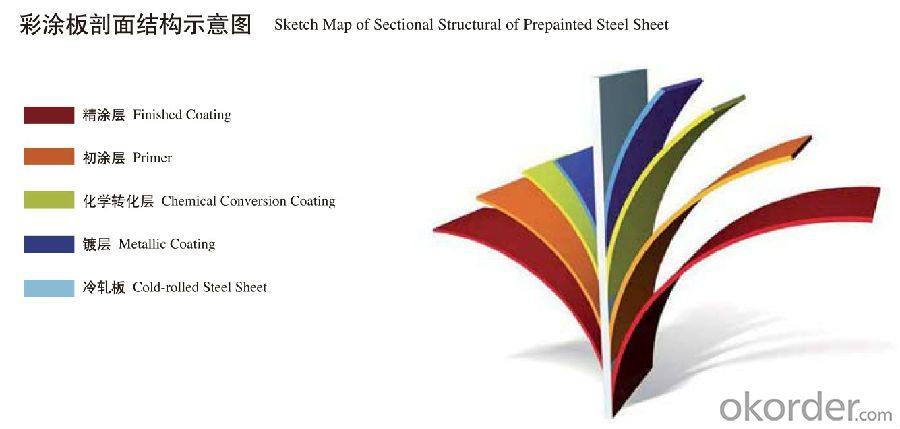

2.Features color coated sheets and coils of bright color/ppgi coils/cold steel coils

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of color coated sheets and coils of bright color/ppgi coils/cold steel coils:

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

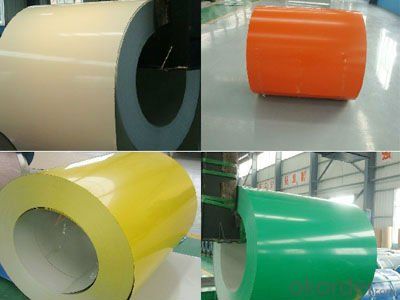

4.color coated sheets and coils of bright color/ppgi coils/cold steel coils image:

APPLICATION:

PROUDUCTION LINE:

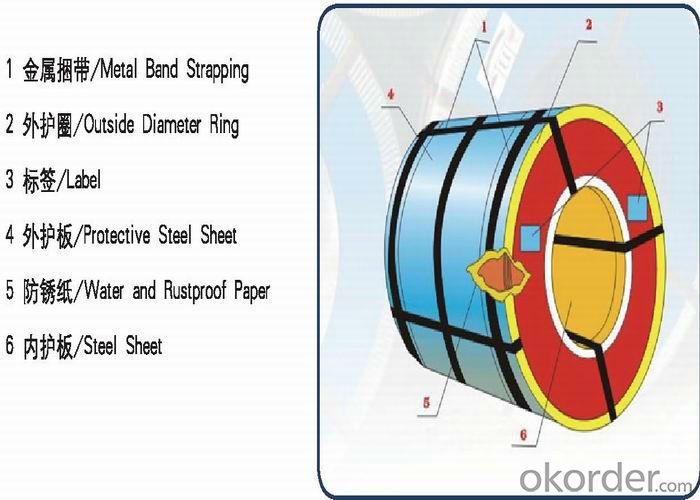

PACKING:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Whats the difference in composition? When LTCS is used generally?Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these?Thankyou very much in advance..

- Low Temperature Carbon Steel

- Q: I was just thinking, is their a way to make steel qualities inherent in concrete, therefore eliminating the need for re bar?

- There is an iron powder reinforced concrete flooring that improves abrasion resistance. However, you cannot get the tensile strength enhancement that is possible with rebar.

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Actually okorder /

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps. Initially, the steel is cleaned and pickled to remove any impurities. It is then passed through a series of rolling mills to reduce its thickness and increase its length. The coils are then annealed to improve their strength and ductility. Further treatments such as galvanizing or coating can be applied to enhance corrosion resistance or improve aesthetic appeal. Finally, the coils are cut and packaged according to customer specifications before being shipped for various applications in industries such as construction, automotive, and manufacturing.

- Q: How is the critical temperature of structural steel affected by fireproofing? What temperatures can fireproofed structural steel withstand?

- mix the fire retardant with cement, let it harden fast to superstructure. this will create better stability and will not be dislodged in case of impact.

- Q: What are the main factors that affect the quality of steel coils?

- The main factors that affect the quality of steel coils include the composition and purity of the steel used, the manufacturing process and techniques employed, the temperature and time of the heat treatment, the level of mechanical stress and strain during rolling and cooling, and the presence of any impurities or defects in the final product.

- Q: Is 440 steel relatively strong or weak?

- Grade 440C is capable of attaining, after heat treatment, the highest strength, hardness and wear resistance of all the stainless alloys. Its very high carbon content is responsible for these characteristics, which make 440C particularly suited to such applications as ball bearings and valve parts. Grades 440A and 440B are identical except for slightly lower carbon contents (0.60 - 0.75% and 0.75 - 0.95% respectively); these have lower attainable hardnesses but slightly higher corrosion resistances. Although all three versions of this grade are standard grades, in practice 440C is more available than the A or B variants. A free-machining variant 440F (UNS S44020) also exists, with the same high carbon content as 440C. Again this grade is not readily available in Australia. Martensitic stainless steels are optimised for high hardness, and other properties are to some degree compromised. Fabrication must be by methods that allow for poor weldability and usually also allow for a final harden and temper heat treatment. Corrosion resistance is lower than the common austenitic grades, and their useful operating temperature range is limited by their loss of ductility at sub-zero temperatures and loss of strength by over-tempering at elevated temperatures. Key Properties These properties are specified for bar product in ASTM A276. Similar but not necessarily identical properties are specified for other products such as plate and forgings in their respective specifications.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are commonly used in the manufacturing of medical equipment to shape and form various components such as frames, supports, and brackets. These coils are often cut, bent, and welded to create the necessary structures that provide strength and stability to the equipment. Additionally, steel coils may be used in the production of springs, which are essential for medical devices that require controlled movement or pressure. Overall, steel coils play a crucial role in enhancing the durability, functionality, and safety of medical equipment.

- Q: What exactly is surgical stainless steel made of (metals)? Does it contain nickel? If so, what % does it usually contain? I am deciding between surgical stainless steel piercings or titanium. Both same price and looks. I want to know which one is more hypo-allergenic and generally nickel free.

- um surgical stainless steel? lets try ... stainless steel... herp derp

- Q: What is the difference between hot-rolled and cold-rolled steel coils?

- Hot-rolled steel coils are produced at high temperatures, resulting in a rough surface and less precise dimensions. Cold-rolled steel coils, on the other hand, are processed at lower temperatures, leading to a smoother surface and more accurate dimensions.

Send your message to us

color coated sheets and coils of bright color/ppgi coils/cold steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords