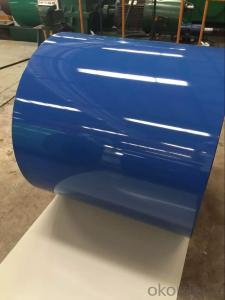

PPGI Prepainted Galvanized Steel Coil for Different size for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications;

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Second Glance of Photo

Galvanzied steel coil( GI, CRC)

Color coated steel coil(PPGI)

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: What are the different types of packaging for steel coils?

- The different types of packaging for steel coils typically include wooden crates, steel frames, and plastic wrapping. These packaging materials are used to provide protection and secure the steel coils during transportation and storage.

- Q: What we have to keep in mind before buying a steel building?

- Before okorder /... Hope this will prove helpful to you.

- Q: what exactly does it mean when some sword makers refer to finding the truth of steel. I have heard that many have tried to find the truth but i dont really understand what there is to find.

- I am unsure of what the Truth of Steel is, but here is the Riddle of Steel (from Conan) Thulsa Doom: Yes! You know what it is, don't you boy? Shall I tell you? It's the least I can do. Steel isn't strong, boy, flesh is stronger! Look around you. There, on the rocks; a beautiful girl. Come to me, my child... Thulsa Doom: [coaxes the girl to jump to her death] Thulsa Doom: That is strength, boy! That is power! What is steel compared to the hand that wields it? Look at the strength in your body, the desire in your heart, I gave you this! Such a waste. Contemplate this on the tree of woe. Crucify him!

- Q: How do steel coil manufacturers ensure employee safety?

- Steel coil manufacturers ensure employee safety through a combination of safety training programs, implementation of safety procedures and protocols, regular equipment maintenance, and providing personal protective equipment. They also conduct regular safety audits and inspections to identify and address any potential hazards in the workplace.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: What are the dimensions of steel coils used in the industrial machinery industry?

- In the industrial machinery industry, the dimensions of steel coils can vary depending on the specific application and requirements. However, it is generally observed that steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The core, or inner diameter, of the coil can range from 508 to 762 millimeters (20 to 30 inches). Furthermore, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may experience variations according to the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

- Q: What are the common challenges faced in steel coil production?

- Some common challenges faced in steel coil production include ensuring consistent quality and dimensional accuracy, managing the high energy consumption involved in the production process, handling and transporting heavy coils safely, and minimizing the risk of surface defects and damage during processing and storage. Additionally, maintaining efficient production speeds, optimizing material utilization, and meeting customer demands for timely delivery can also pose challenges in steel coil production.

- Q: What are the common coil thicknesses available for steel coils?

- The common coil thicknesses available for steel coils can vary depending on the specific application and industry requirements. However, some of the most common coil thicknesses for steel coils range from 0.5mm to 3mm. These thicknesses are commonly used in various manufacturing processes, including automotive, construction, and appliance industries. For lightweight applications or where flexibility is required, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often used. These thinner coils are suitable for applications such as automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that require higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are commonly used. These thicker coils are often utilized in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to note that these are just general ranges, and specific coil thicknesses can vary depending on the specific requirements of a particular project or customer preference. Steel coil thicknesses can be customized to meet specific needs, allowing for greater flexibility in various industries.

- Q: A roll of 1 meters wide color steel roll about how many tons?

- Color steel roll is a composite material, both steel and organic materials, both of them a little. Both the mechanical strength of steel plate and easy molding performance, but also organic materials, good decoration, corrosion resistance. 1 meters wide should also have length, wall thickness conditions to know how many tons. The manufacturer is generally in accordance with customer requirements into a volume, the normal width of 1 meters per roll over 1 tons.

- Q: What are the common coil surface treatments available for steel coils?

- There are several common coil surface treatments available for steel coils, each serving different purposes and offering various benefits. These treatments aim to enhance the durability, corrosion resistance, and appearance of the steel coils. 1. Galvanized Coating: Galvanization is a popular treatment in which a layer of zinc is applied to the steel coil's surface. This coating provides excellent corrosion protection, preventing rust and extending the lifespan of the coil. It is commonly used in outdoor applications or environments with high humidity levels. 2. Phosphating: Phosphating is a chemical treatment that forms a thin layer of phosphate coating on the steel coil's surface. This treatment enhances the adhesion of subsequent coatings and improves the coil's paintability. It also offers some corrosion resistance and can be used as a pre-treatment before painting or powder coating. 3. Chromate Conversion Coating: Chromate conversion coating, also known as chem film or Alodine, involves applying a thin layer of chromate to the steel coil's surface. This treatment offers corrosion protection and acts as a primer for subsequent coatings, improving their adhesion. It is often used in aerospace and electrical applications. 4. Powder Coating: Powder coating is a dry finishing process in which a fine powder is applied to the steel coil's surface electrostatically and then cured under heat. This treatment provides a durable and attractive finish, offering excellent resistance to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile option. 5. Organic Coatings: Organic coatings, such as acrylic, polyester, or polyurethane, are applied to the steel coil's surface as liquid paints. These coatings provide aesthetic appeal, protection against corrosion, and resistance to weathering and UV radiation. Organic coatings are often used in architectural and automotive applications. 6. Anodizing: Anodizing is a treatment primarily used for aluminum coils but can also be applied to steel coils. It involves creating an oxide layer on the surface of the coil through an electrochemical process. This treatment enhances the coil's corrosion resistance and provides an attractive finish. Anodizing is commonly used in architectural and decorative applications. It's important to note that the choice of coil surface treatment depends on the specific requirements of the application, including the desired performance, aesthetics, and environmental factors. Consulting with a professional in the steel industry can help determine the most suitable treatment for a particular project.

Send your message to us

PPGI Prepainted Galvanized Steel Coil for Different size for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords