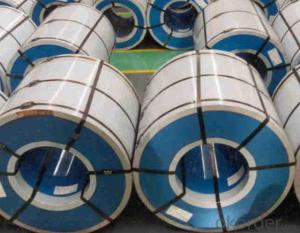

supply High Quality Prepainted steel coil/EM/color coated steel coil/PPGI/PPGL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,GB,JIS | Grade: | SGCC/DX51D | Thickness: | 0.17-1.6mm |

| Place of Origin: | HEB,hebei, china China (Mainland) | Brand Name: | CNBM | Model Number: | WL-100 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | building material, roofing, household appliance, etc. | Special Use: | High-strength Steel Plate | Width: | 58-1250mm |

| Length: | 339-5243M | Color: | red green blue white brick red 3005 6005 8017 5005 9006 9003 RAL Color | WL01: | PPGI 150-3 |

| Factory: | Bazhou shengfang winroad building materials co.,ltd |

Packaging & Delivery

| Packaging Detail: | Standard export and seaworthy packing. i.e. waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil(or according to customer's requests),.. |

| Delivery Detail: | 30 days after receiving prepayment or original L/C. |

Specifications

supply High Quality Prepainted steel coil/EM/color coated steel coil/PPGI/PPGL

Grade:SGCC,DX51D,CGCC

Thick:0.17-0.8

High Quality Prepainted steel coil

color color prepainted galvalnized steel coils

Mill of Pre Painted color coated steel plate/sheet(thick:0.17-1.2mm)

Brief Introduction

1. Color steel is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color steel consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color steels can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color steel has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color steels can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

6.We are supplying Secondry quality/Over Rolled/Galvanized/Prepainted/Steel sheet & Coils with thickness Of 0.25 mm to 0.50 mm, width 950 and above.

We are also supplying cr base color coils/embossed coils with thickness 0.35 mm to 0.50mm. Contact me please, then when i have the list, i will send you ASAP.

Certificate: ISO 9001/14001

The main specification is as belows:

Standards: GB/T12754, JIS3312 , EN 10169 ASTM A755

Thickness: 0.14-0.8mm; Width: 914-1250mm

Tolerance : +2/0mm,thickness tolerance :+0.02/-0.02mm (or according to customers' request).

Coating mass: Top;13-25, Back: 5-10

Coil weight: 5-8 metric tons

Coil DM: I.D: Φ508m/610mm O.D: Max Φ1500mm

Coating type: PE, SMP, HDP, PVDF

Common performance of front coating:

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

Application

1. Construction: (Outside) workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door

(Inside) door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter

2. Electrical appliance: refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

3. Furniture: central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf

4. Carrying trade: exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

5. Others: writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

NAME

| PPGI | GALVANIZED

| GALVALUME/ALUZINC

|

CERTIFICATE | ISO9001 | ||

STANDARD

| GB/T-12754 JIS G 3312 EN 10169 ASTM A755 | GB/T-2518 JIS G 3302 EN 10142/10427 ASTM A653 | GB/T-14798 JIS G 3321 EN 10215 ASTM A792 |

GRADE

| SGCC DX51D SGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

MODEL NO | 0.16MM-1.0MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

TYPE

| Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc

|

SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

APPLICATION | Structural use ,roofing, corrugated roofing, commercial use, household appliance, industry, family | ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

- Q: How are steel coils used in the manufacturing of storage shelves?

- Steel coils are used in the manufacturing of storage shelves by being formed and shaped into the desired dimensions and designs. These coils are often cut, bent, and welded to create the frame and shelves of the storage unit. The strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of the shelves.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are typically processed for cutting to length or blanking through a series of steps. First, the coils are unwound using a machine called an uncoiler, which feeds the steel into the cutting process. Then, the steel passes through a leveler to ensure a flat surface. Next, it enters a shear or blanking process, where the steel is cut into desired lengths or shapes. Finally, the cut pieces are stacked or packaged for further use or distribution.

- Q: How do steel coils contribute to the marine industry?

- The marine industry heavily relies on steel coils due to their multiple uses that contribute to the advancement, upkeep, and effectiveness of marine vessels. Initially, steel coils are crucial in ship and offshore platform construction. Their exceptional strength and durability make them ideal for the hull structure, ensuring the vessel's integrity and safety, even in harsh marine conditions. Furthermore, steel coils find application in the production of various marine equipment and parts. For example, they are utilized in the manufacturing of propellers, shafts, and rudders, which are vital for steering and propelling ships. By using steel coils in these components, their ability to withstand the corrosive impact of seawater is ensured, thereby prolonging their lifespan and reducing maintenance expenses. Moreover, steel coils play a significant role in the fabrication of marine pipelines and infrastructure for oil rigs. These coils are transformed into pipes and tubes that are essential for transporting oil, gas, and other fluids. The strength and corrosion resistance of steel coils are crucial in guaranteeing the dependability and safety of these pipelines, as they must endure extreme pressure and exposure to saltwater. Additionally, steel coils are also involved in the maintenance and repair processes of the marine industry. Whenever a ship undergoes renovations or repairs, damaged or corroded sections are often replaced with steel coils. The versatility of steel coils enables them to be molded and welded into various shapes and sizes, making them suitable for diverse repair applications. Overall, steel coils make a substantial contribution to the marine industry by providing the necessary strength, durability, and corrosion resistance required for the construction, maintenance, and efficiency of marine vessels. Their utilization in shipbuilding, component fabrication, pipeline construction, and repair procedures renders them indispensable for the growth and sustainability of the marine industry.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Steel manufacturers have the capability to produce coils in various sizes and thicknesses to meet the specific requirements of customers. This allows for flexibility in applications and ensures that the steel coils can be tailored to suit different industries and projects.

- Q: What are the common coil packaging materials?

- Common coil packaging materials include plastic wrap, stretch film, steel strapping, and wooden crates. These materials are used to protect and secure coils during storage and transportation, ensuring they remain intact and undamaged.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- Quite a few companies make stainless steel cleaners. Don't use Windex, I was told when we bought our stainless fridge and stove. Go to Home Depot or a store like it and I am sure they will have some to choose from. I bought these pre-treated wipes for Stainless Steel at Bath Beyond (like Lysol makes) and they work wonders for a quick cleaning. Linens N Things also has some wipes.

- Q: what do they use to make stainless steel?and can stainless steel be melted again and again without losing it's Specifications

- Components Of Stainless Steel

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are applied to the surface of the steel coils to provide added protection against wear and tear caused by friction and other abrasive forces. This coating helps prolong the lifespan of the steel coils and maintain their performance in various applications.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

- Q: How are steel coils used in the appliance industry?

- Steel coils are commonly used in the appliance industry for various purposes such as manufacturing washing machines, refrigerators, dishwashers, and other household appliances. These coils are typically used to form the structure of the appliances, provide strength and durability, and support the weight of various components. The steel coils are also used in the production of heating elements, motors, and other key components that ensure the efficient operation of appliances.

Send your message to us

supply High Quality Prepainted steel coil/EM/color coated steel coil/PPGI/PPGL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords