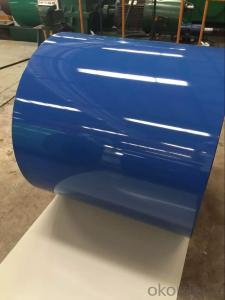

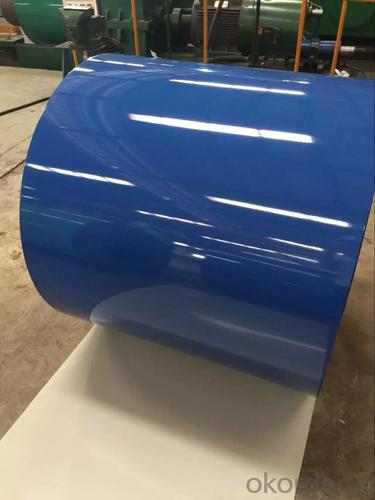

PPGI Steel coils factory Prepainted color steel coil for roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We have devoted to manufacture steel coils for 13 years. As the biggest manufacture in Hebei China, we have two large factory and 8 production lines, sincerely welcome to your visit if possible.

1, Production Introduction: PPGI are prepainted galvanized steel coils, used for making roof, advantage is can be used at least 10 years.

2, Product feature:

① We're factory, products has the best price for you.

② We have 8 production lines, have the fastest delivery time for order

③ All colors can be produced by our factory.

④ Product can accept any test before shipment.

3,Parameter list:

① Product Name:PPGL

②Thickness:0.2-1.0MM

③ Width:914-1250MM

④ Az Coating:30-275 G/M2

⑤Coil Weight:3-5MT

⑥Coil ID:508MM

⑦Packing :Standard Export Seaworthy Shipping Packaging

⑧Payment Terms:30% T/T in advance, 70% balance within 3 working days against the copy of B/L Or irrevocable LC at sight

⑨Delivery Time:

10 days after advance is confirmed if order≤100MT

15 days after advance is confirmed if 100MT≤order≤200MT

20 days after advance is confirmed if 200MT≤order

4,

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q: I bought a steel pendant on eBay, but it turned out to be too shiny.I've read on a couple forums that if I leave it soaked in urine for 2 days, it will get duller.Now, if it really does get duller, will the pendant get rusty afterwards?So is the shiny surface the only thing that prevents it from rusting?Any simple, non-urine ideas on how to make it duller are welcome too.Thanks!

- Stainless steel will rust under proper conditions. I live on a boat on salt water, trust me. If the urine works it won't be prone to rusting any more than before. It's not the shine that inhibits rusting with stainless steel, it the % of carbon in the steel, compared to regular steel. IF the urine works it's because it is acidic (a mild acid). Wash it with a small brush and some baking soda to neutralize the acid when your done. A much stronger acid would be swimming pool acid. (Muriatic acid) but be careful you might test a spot with a Q tip on the back. If you try Muriatic acid it would take seconds.Then wash in baking soda water to remove all acid.. SS

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Rock pokemon are weak against steel type moves.

- Q: How do steel coils contribute to energy efficiency in appliances?

- Steel coils contribute to energy efficiency in appliances in several ways. Firstly, steel coils are commonly used in the heat exchangers of appliances such as refrigerators, air conditioners, and water heaters. These coils transfer heat efficiently, allowing appliances to cool or heat the desired space using less energy. By maximizing heat transfer, steel coils help appliances reach the desired temperature faster and maintain it with minimal energy consumption. Secondly, steel coils are often used in the heating elements of appliances like stoves and ovens. These coils provide direct heat to cook or bake food. Steel's excellent thermal conductivity ensures that the heat is evenly distributed, reducing cooking time and energy consumption. This allows appliances to work more efficiently, saving both time and energy. Furthermore, steel coils are durable and long-lasting, which contributes to energy efficiency in appliances. Appliances with steel coils are built to withstand high temperatures and frequent use. This means they require less maintenance and replacement, resulting in fewer resources being used to produce new appliances. By reducing waste and conserving resources, steel coils indirectly contribute to energy efficiency and sustainability. Lastly, steel is a recyclable material. When appliances reach the end of their life cycle, the steel coils can be recycled and used to produce new products. Recycling steel reduces the need for extracting raw materials and saves energy that would otherwise be required in the manufacturing process. This promotes energy efficiency and reduces the environmental impact of appliances. In conclusion, steel coils contribute to energy efficiency in appliances by optimizing heat transfer, reducing cooking time, promoting durability, and facilitating recycling. These factors collectively help appliances operate more efficiently, save energy, and contribute to a more sustainable future.

- Q: What are the different grades of steel used in manufacturing steel coils?

- There are several different grades of steel that are commonly used in manufacturing steel coils. These grades include carbon steel, stainless steel, and high-strength low-alloy steel (HSLA). Each grade has its own unique properties and characteristics, which make them suitable for specific applications in various industries.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Stainless steel is not rust proof. it's just rust resistant. It will rust. It just takes much longer to do so... So, yes, I'd dry it well after use, and even consider wiping it with a cloth containing a very lite coating of oil.

- Q: What are the different methods of steel coil surface cleaning?

- Some of the different methods of steel coil surface cleaning include pickling, shot blasting, and chemical cleaning. Pickling involves immersing the steel coil in an acid solution to remove oxides and scales. Shot blasting uses high-speed particles to remove rust, scale, and paint from the surface. Chemical cleaning involves using specialty chemicals to dissolve contaminants and restore the steel coil's surface.

- Q: What are the applications of steel coils in the aerospace industry?

- Steel coils have several important applications in the aerospace industry. One of the key uses is in the manufacturing of aircraft structures. Steel coils are commonly used in the fabrication of various components such as wing spars, fuselage frames, and landing gear. The high strength and durability of steel make it an ideal material for these critical parts, as they need to withstand heavy loads and extreme conditions. Another application of steel coils in the aerospace industry is in the production of engine components. Steel coils are used to manufacture turbine blades, which are subjected to high temperatures and rotational forces. The excellent heat resistance and mechanical properties of steel make it suitable for these demanding applications, ensuring the reliability and performance of aircraft engines. Steel coils are also utilized in the production of fasteners and connectors used in the aerospace industry. Fasteners such as bolts, nuts, and rivets made from steel coils are crucial for joining different parts of an aircraft securely. These fasteners need to have high tensile strength and corrosion resistance to ensure the structural integrity and safety of the aircraft. Additionally, steel coils find application in the production of fuel tanks and hydraulic systems. The excellent weldability and formability of steel allow for the efficient fabrication of these complex structures. Steel coils can be shaped into different sizes and configurations, providing flexibility in designing fuel tanks and hydraulic components that meet specific requirements. In summary, steel coils play a vital role in the aerospace industry. Their use in aircraft structures, engine components, fasteners, and fuel tanks showcases their versatility and reliability. The exceptional strength, durability, heat resistance, and formability of steel make it a preferred material for various aerospace applications, ensuring the safety and performance of aircraft.

- Q: I beat fallout 3 and i downloaded broken steel expansion. I have no idea how to get to broken steel in other words i do not know how to start playing it.

- Sorry, all three above are wrong. Once Broken Steel is downloaded via windows live it's supposed to start automatically, but if it's not then one should launch Fallout 3 from the Fallout3Launcher.exe and in the Data Files section checkmark Broken Steel before hitting Play Game. Then, if you've done everything right, no matter if you're first level stuck in Vault 101 or 20th level playing for 69 hours, in about a minute or so a message will appear saying that Broken Steel is installed and that your level cap has been raised from 20 to 30. Even if you don't proceed through the main quest to the new Broken Steel quests, Broken Steel content will still appear in your game, from Supermutant Overlords with Tri-Laser Rifles to Albino Radscorpions, they're all out there in random encounters. Broken Steel is how the game should've been released from the beginning if Bethesda had any conscience, but now that we've got it, enjoy it.

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they serve as the primary material for constructing the bridge's structural components, such as beams and girders. These coils are processed through various stages, including cutting, shaping, and welding, to create the necessary structural elements that provide strength and support to the bridge. The durability and load-bearing capacity of steel coils make them ideal for withstanding the heavy loads and stresses experienced by bridges, ensuring their stability and longevity.

Send your message to us

PPGI Steel coils factory Prepainted color steel coil for roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords