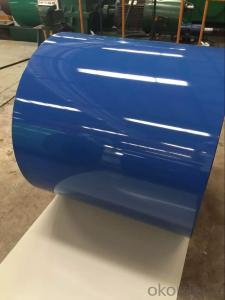

PPGI/Pre-painted Galvanized Steel for Roofing/Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Prepainted Galvanized Steel Coil:

1) Capacity: about 15,000 tons per month for coil product

2) Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

3) Grade: Q195-Q235 and SPCC, SPCD, SPCE, SGCC (DX51D+Z) SGCD (DX52D+Z), etc.

4) Thickness: 0.13mm-2.0mm

5) Zinc coating weight: 60-275g/m2

6) Width: 600mm-1250mm, or according to the customer's request.

7) Coil ID: 508mm-610mm

8) Coil Weight: according to the customer's request

9) Color: RAL, or other series

10) Surface protection: PE, PVDF, SMP, HDP, etc.

11) Surface treatment: chromate, oil/unoil, bright finish, spangle, anti-finger print

12) Min trial order: 25 ton each size, 1x20' per delivery

Advantages of Our Prepainted Galvanized SteelCoil:

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Prepainted Galvanized SteelCoil:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

| Project | Pencil hardness | Reverse impact | T bending | Cupping test | MEK cleaning |

| Front/back | ≥ H/2H | ≥ 9J/6J | ≤ 3T/5T | ≥ 6mm/4mm | ≥ 100time/50time |

Structure of GI/PPGI

| Item | Thickness | Type | Feature |

| Laminated film | 50μm | Polyethylene | Protecting from scratchs and contamination (option) |

| Top coat | 20μm | Polyester Fluorine | Chemical resistance and formability |

| Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

| Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

| Substrate | 0.2mm-1.2mm | GI.GL,AL | GI.GL,AL |

| Back coat | 5±2μm | Epoxy | Corrosion resistance and adhesion to the substrate |

- Q: I need to know which cookware set is better. We are trying to get rid of the ones we have here. They are Teflon. I have heard that stainless steel (aluminum) and hard Ionized are good, but which is the best one.

- A good quality stainless steel cookware set is a necessity- it is virtually indestructible and you can use the harshest of scrubbers to clean it. You will need a basic set that has a 8 and 12 fry pan/omelet pan, a large pot that holds a minimum of 4 quarts, and 2 sauce pots at 1 quart and 2 1/2 quart sizes. I have several pieces of hard anodized cookware too- they do a wonderful job but food will still stick. A must is at least one Green Pan- preferably a 10-12 fry pan. They are truly non-stick, clean up is a breeze and making foods like fried eggs is infinitely easier when they slide out of the pan without breaking. They do not have the same issues that plague teflon pans- scrapes and shedding that you are ultimately consuming. You can easily find them online and at your area Target store.

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- The young man in the video is using a steel string guitar. Steel string guitars can be played fingerstyle or with a pick. Classical guitars use nylon strings and are only played fingerstyle. Classical guitars are used almost exclusively for playing classical music. If you're not interested in playing classical music then it's the wrong guitar for you. Steel string guitars can be used for a wide range of musical styles from pop to rock to folk to bluegrass to country, and more. Don't worry about pain - your fingers will hurt at first with either nylon or steel strings but that passes quickly. Buy the guitar that's most appropriate for the music you want to play.

- Q: How are steel coils used in the production of metal ceilings?

- Steel coils play a vital role in the manufacturing of metal ceilings. Typically composed of high-quality steel, these coils serve as the fundamental material for fabricating metal ceiling panels. To commence the process, the steel coils are uncoiled and fed into a roll forming machine. Gradually, this machine shapes the steel into the desired profile for the ceiling panels. The coils pass through a series of rollers that bend and mold the steel into the necessary dimensions and design. Once the steel has taken its desired shape, it is cut into individual panels of the required length. These panels then undergo various finishing processes, including surface treatment, painting, or powder coating, to enhance their appearance and durability. Steel coils are the preferred choice for producing metal ceilings due to their exceptional strength and rigidity. They establish a robust foundation for the ceiling panels, ensuring their longevity and resistance to deformation. Additionally, steel coils offer superior fire resistance, making them a safe option for commercial and industrial buildings. Apart from their structural advantages, steel coils also allow for a wide array of design possibilities. The malleability of steel enables manufacturers to create intricate patterns and textures on the surface of the ceiling panels, adding aesthetic appeal and enhancing the overall interior design. In summary, steel coils are an essential component in the production process of metal ceilings. They possess the necessary strength, durability, and versatility for crafting high-quality and visually pleasing ceiling panels utilized in various commercial and residential settings.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- There are several methods of cut-to-length shearing for steel coils, each with its own advantages and applications. Some of the commonly used methods are: 1. Rotary Shearing: This method involves the use of a rotating shear blade that cuts through the coil. It offers high precision and can handle a wide range of material thicknesses. Rotary shearing is suitable for high-volume production and can achieve high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is used to cut through the coil. It is a versatile method that can handle various material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves making multiple longitudinal cuts in the coil to create narrower strips. It is commonly used when a coil needs to be divided into several smaller coils or when narrower strips are required for specific applications. Slitting can be done using either rotary or straight blades. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the material, resulting in a clean and precise cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through the coil. This method is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often used for cutting thick coils or when heat-affected zones need to be minimized. Each method has its own strengths and limitations, and the choice depends on factors such as material thickness, required precision, production volume, and specific application requirements. The selection of the most appropriate method is crucial to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- we may use the formula ΔL=α(Lo)(Tf-To) where Lf is the length of steel at temp. Tf Lo is length at To α is the coefficient of linear expansion of steel which is 11x10^-6/°C ΔL=0.78mm (the change in length) Lo=? ΔL=α(Lo)(Tf-To) Lo=ΔL/[α(Tf-To)] Lo=(0.78x10^-3m)/[(11x10^-6/°C)(35°C-2...? Lo=5.455m answer

- Q: How do steel coil manufacturers ensure product quality?

- Superior quality steel coils are produced by steel coil manufacturers who employ a rigorous quality control process and adhere to industry standards. Firstly, they carefully select trusted suppliers who provide high-quality raw materials. This guarantees that the base material used in manufacturing the coils is of exceptional quality. During the production process, manufacturers implement strict quality control measures. They utilize advanced technologies and machinery to closely monitor parameters like thickness, width, and weight of the coils. This ensures consistency and accuracy in the dimensions and specifications of the products. To guarantee the durability and strength of the steel coils, manufacturers subject them to various tests such as tensile strength testing, yield strength testing, and elongation testing. These tests determine the mechanical properties of the coils and ensure that they meet the required standards. In addition to these tests, manufacturers conduct thorough inspections of the coil surfaces to identify any defects or imperfections. They utilize techniques like visual inspection, ultrasonic testing, and magnetic particle inspection to detect any surface irregularities that may affect the quality of the product. Furthermore, steel coil manufacturers adhere to international quality standards such as ISO 9001. This ensures that their manufacturing processes are consistently meeting the required quality benchmarks. They also maintain regular communication and collaboration with customers to understand their specific requirements and incorporate any necessary changes to enhance product quality. Overall, steel coil manufacturers prioritize product quality through a combination of strict quality control measures, adherence to industry standards, and continuous improvement practices. This guarantees that the steel coils they produce are of the highest quality and exceed the expectations of their customers.

- Q: How do steel coils contribute to the manufacturing of oil and gas equipment?

- Steel coils are an essential component in the manufacturing of oil and gas equipment. These coils are typically made from high-quality steel that is durable, strong, and resistant to corrosion, making them ideal for withstanding the harsh environments and conditions encountered in the oil and gas industry. One of the primary applications of steel coils in oil and gas equipment manufacturing is in the fabrication of pressure vessels. Pressure vessels are crucial components used for storing and transporting various fluids and gases under high pressure. Steel coils are used to form the cylindrical shells of these vessels, providing the necessary strength and structural integrity to withstand the internal pressure. Steel coils are also utilized in the construction of oil and gas pipelines. These pipelines are responsible for transporting vast quantities of oil and gas over long distances. Steel coils are used to manufacture the pipes that make up these pipelines, providing the necessary strength, durability, and resistance to corrosion. The coils are rolled and welded to form seamless or welded pipes, which are then coated or lined to prevent corrosion and enhance their longevity. Furthermore, steel coils are instrumental in the production of drilling equipment used in the extraction of oil and gas. This equipment includes drill bits, casings, and wellheads, which are crucial for drilling and completing wells. The coils are used to fabricate these components, ensuring they can withstand the demanding conditions encountered during drilling operations. In addition to their structural applications, steel coils are also used in the manufacturing of ancillary equipment such as tanks, storage containers, and heat exchangers. These components play a vital role in the processing, storage, and distribution of oil and gas. Steel coils provide the required strength and durability to handle the harsh conditions and corrosive substances encountered in these processes. Overall, steel coils are indispensable in the manufacturing of oil and gas equipment. Their strength, durability, and resistance to corrosion make them a preferred choice in the industry. By contributing to the fabrication of pressure vessels, pipelines, drilling equipment, and ancillary components, steel coils ensure the safe and efficient extraction, processing, and transportation of oil and gas.

- Q: How are steel coils used in the manufacturing of seat belts?

- Steel coils are used in the manufacturing of seat belts to provide strength and durability. The steel coils are typically used as the main structural component in the seat belt, ensuring that it can withstand high levels of force during an impact. Additionally, the coils help to maintain the proper tension in the seat belt, ensuring that it functions effectively in restraining the occupants in the event of a collision.

- Q: How are steel coils used in the agricultural sector?

- Steel coils are widely used in the agricultural sector for various purposes. One of the main uses is in the construction of farm machinery and equipment. Steel coils are often used in the manufacturing of tractors, plows, harvesters, and other heavy-duty machinery. The strength and durability of steel make it an ideal material for these applications, as it can withstand the demanding conditions of agricultural work. Additionally, steel coils are used in the construction of agricultural buildings and structures. Steel is known for its high structural integrity, making it a popular choice for barns, storage units, and other agricultural facilities. Steel coils are often used to create the framework and support systems of these structures, providing stability and long-lasting durability. Moreover, steel coils are used in the production of irrigation systems. The pipes and tubes used for transporting water in agricultural irrigation systems are often made from steel coils. Steel's resistance to corrosion and its ability to handle high-pressure flows make it an excellent choice for this application. In summary, steel coils play a crucial role in the agricultural sector. From the construction of farm machinery and buildings to irrigation systems, steel's strength and durability make it a preferred material in the industry.

- Q: What are the common methods of welding steel coils?

- The common methods of welding steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

Send your message to us

PPGI/Pre-painted Galvanized Steel for Roofing/Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords