PPGI Color Coated Steel Sheet or Steel Coil in Red

- Loading Port:

- shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

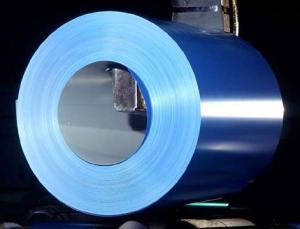

3. Color Coated GI/GL Steel Coil Images

4.Color Coated GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the manufacturing of storage tanks?

- Steel coils are used in the manufacturing of storage tanks as they serve as the primary material for constructing the tank shell. The coils are processed and shaped into cylindrical sections, which are then welded together to form the tank. This ensures strength, durability, and leak-proof construction, making steel coils an essential component in the fabrication process of storage tanks.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they are rolled into sheets, which are then cut and welded to create the walls, roof, and floor of the container. The high strength and durability of steel coils ensure that the shipping containers can withstand the rigors of transportation, protecting the goods inside.

- Q: How are steel coils used in the production of steel wire?

- Steel coils are used in the production of steel wire by being uncoiled and fed into a wire drawing machine. The steel wire is then drawn through a series of dies to reduce its diameter and increase its length. The coils provide a continuous and consistent supply of steel, ensuring a smooth and efficient production process.

- Q: What are the common tests performed on steel coils?

- The common tests performed on steel coils include dimensional inspection, visual inspection, tensile testing, hardness testing, bend testing, and surface quality assessment. These tests ensure the quality, strength, and integrity of the steel coils before their use in various applications such as construction, automotive, and manufacturing.

- Q: How are steel coils processed for different finishes?

- Steel coils are processed for different finishes through various techniques such as hot rolling, cold rolling, pickling, and coating. Hot rolling involves heating the steel coils and passing them through rollers to achieve desired thickness and shape. Cold rolling further enhances the surface finish by reducing thickness and increasing strength. Pickling involves removing impurities and scale from the surface of the steel coils using acid solutions. Finally, coating techniques like galvanization or painting are used to provide protective and decorative finishes to the steel coils.

- Q: Is sterling silver better than surgical steel as far as being hypoallergic in earrings? If I have a choice which should I get? Thanks!

- Surgical okorder /

- Q: would you consider steel a flexible substance...i am debating this with my coworkers.Thanks,

- Yes, steel is flexible. Springs, like the ones holding up your car, are made out of steel. One reason why steel skyscrapers do so well in earthquakes is because steel is flexible. Piano wires are made out of steel. High tension wires for electric power transmission are made out of steel. Even a solid block of hard steel can actually bend and spring back, although it's very hard to see this tiny flexure.

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are typically detected through visual inspections, as well as non-destructive testing techniques such as ultrasonic testing and magnetic particle inspection. Once identified, the defects can be resolved through various methods including grinding, welding, or cutting and replacing the affected area. The specific resolution method depends on the nature and severity of the defect.

- Q: density of mild steel (MS) is 7850 KG per metre cube , but i want to know the density of stainless steel

- Stainless steels are the most dense, coming in at 8000 kg/m3. Though the densities vary, The answer is 8000 kg/m3. 301 stainless density values seem to vary according to the supplier data sheets, from 7.88 g/cc, (AK Steel) to 8.03 g/cc, (Allegheny Ludlum)

- Q: How are steel coils used in the manufacturing of doors and windows?

- Steel coils are used in the manufacturing of doors and windows as they provide a strong and durable material for constructing the frames and components. The coils are first processed and cut into the desired shape, then formed and welded together to create the frames. This ensures stability and support, allowing the doors and windows to withstand various weather conditions and provide long-lasting performance.

Send your message to us

PPGI Color Coated Steel Sheet or Steel Coil in Red

- Loading Port:

- shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords