Color Coated GI/GL Steel Sheet or Steel Coil in Red Color

- Loading Port:

- shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

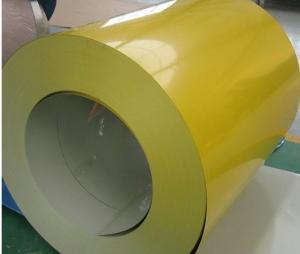

3. Color Coated GI/GL Steel Coil Images

4.Color Coated GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- cold rolled steel waers as you carve meat. If the blad if to thin you may want a better one. Utica knife in utica N.Y. made them up to about 10 years ago and i still buy them at auctions.

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific type and purpose of the coil, but it typically falls within the range of 600 mm (23.6 inches) to 2,200 mm (86.6 inches).

- Q: What are the common applications of stainless steel coils?

- Stainless steel coils possess unique properties and characteristics that allow for a wide range of applications. Some of the most frequently seen uses for stainless steel coils include the following: 1. Automotive industry: The automotive industry extensively incorporates stainless steel coils in the manufacturing of components such as exhaust systems, mufflers, and catalytic converters. These applications benefit from stainless steel's corrosion resistance and durability, making it an ideal choice. 2. Construction industry: The construction industry heavily relies on stainless steel coils for structural elements, roofing, cladding, and facades. Stainless steel's high strength, resistance to corrosion, and aesthetic appeal make it a popular choice for architectural projects. 3. Kitchen appliances: Stainless steel coils are commonly utilized in the production of kitchen appliances like refrigerators, stoves, ovens, and dishwashers. Stainless steel's easy cleanability, resistance to heat and stains, and hygienic properties make it the preferred material for these applications. 4. Food processing industry: The food processing industry widely employs stainless steel coils for equipment such as tanks, pipes, and conveyor systems. Stainless steel's corrosion resistance and ease of cleaning ensure the integrity and hygiene of food products. 5. Medical industry: The medical industry extensively utilizes stainless steel coils for various applications, including medical devices, surgical instruments, and implants. Stainless steel's biocompatibility, strength, and resistance to corrosion make it an ideal material for these critical healthcare applications. 6. Energy sector: Stainless steel coils play a crucial role in the energy sector for applications such as heat exchangers, boilers, and pipelines. Stainless steel's high-temperature resistance, excellent mechanical properties, and corrosion resistance make it suitable for these demanding applications. 7. Chemical industry: The chemical industry employs stainless steel coils for storage tanks, piping systems, and reactors. Stainless steel coils are a reliable choice due to their corrosion resistance and ability to withstand high temperatures and aggressive chemicals when handling various chemical substances. 8. Manufacturing industry: Stainless steel coils find extensive use in various manufacturing processes like stamping, forming, and fabrication. The versatility, durability, and ease of machining of stainless steel make it a popular choice for a wide range of industrial applications. In conclusion, the applications of stainless steel coils are vast and varied, thanks to their exceptional properties such as corrosion resistance, strength, durability, and aesthetic appeal.

- Q: What are the dimensions of steel coils used in the industrial machinery industry?

- The dimensions of steel coils used in the industrial machinery industry can vary depending on the specific application and requirements. However, generally speaking, steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The inner diameter of the coil, known as the core, can range from 508 to 762 millimeters (20 to 30 inches). Additionally, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may be subject to variations based on the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

- Q: Can you suggest me names of sites which aids in construction of Pre Fabricated Steel Buildings.

- I okorder /... NCI produces many brand name buildings. Kirby Pasco If you get technical with your question I probably can help you. I have sold many millions of dollars worth of them. Depending on the manufacturer the directions are usually easy to follow. The only suggestion I have is avoid the brokers. Try and deal directly with the manufacturer. The construction plans are usually specific to your building not generic plans like some brokers have.

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are used in the production of steel pipes by being unwound and fed through a series of rollers that shape and weld the steel into a seamless or welded pipe.

- Q: A roll of 1 meters wide color steel roll about how many tons?

- In general, between 3.5 and 5 tons. Our company uses 0.17*1000 white color steel roll. The weight is usually around 4.5 tons. Different manufacturers will have different sealing rolls.

- Q: What are the common coil sizes available for steel coils?

- The common coil sizes available for steel coils vary depending on the specific industry and application. However, there are several standard coil sizes that are commonly used across different sectors. These include 36-inch, 48-inch, 60-inch, and 72-inch coil widths. In terms of coil diameter, the most common sizes are typically between 20 inches and 24 inches. Additionally, coil weights can range from a few thousand pounds to several tens of thousands of pounds, depending on the type of steel being coiled and the intended use. It is important to note that these sizes may vary among different steel manufacturers, so it is always advisable to consult the specific supplier or industry standards to determine the available coil sizes for a particular steel product.

- Q: How are steel coils used in the production of appliances?

- Steel coils are used in the production of appliances as a primary material for constructing the various components, such as the outer shells, frames, and internal structures. The coils are processed and shaped into specific sizes and forms to meet the requirements of different appliances. Additionally, steel coils provide strength, durability, and a sleek appearance to the finished appliances.

Send your message to us

Color Coated GI/GL Steel Sheet or Steel Coil in Red Color

- Loading Port:

- shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords