PPGI Anti-Finger Print Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPGI Anti-Finger Print Steel Coil description:

Standard:AISI,ASTM,BS,DIN,GB

Thickness:0.15-1.0mm

Surface Treatment:Coated

Application:Building material

Width:600-1250mm

Zinc coating:40-120g/m2

Hardness of pencil:>/=2H

Gloss:32-85%

T- Bend:0-3t

Coil ID:508/610mm

Backside painting:7-10mic

Upside painting:13-25mic

PPGI Anti-Finger Print Steel Coil Packaging & Delivery:

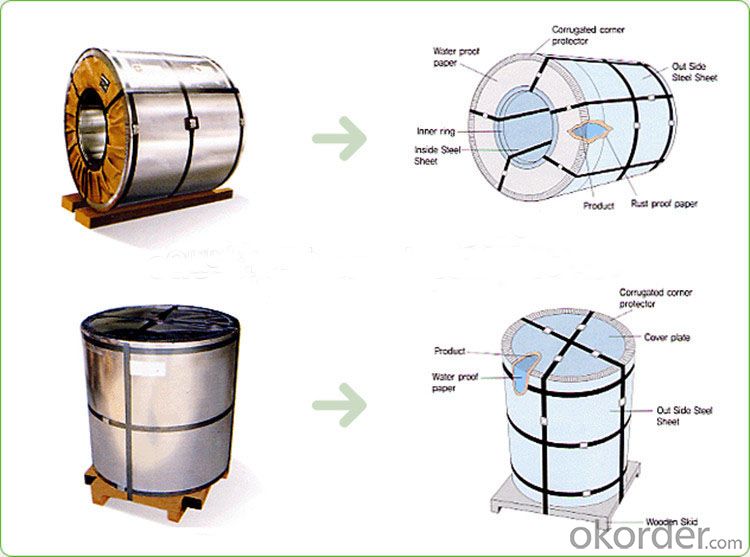

Packaging Detail:standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Delivery Detail:15-30days

specification:

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Hot dipped galvanized steel coil |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-15days after signing contract |

Price | FOB&CNF&CIF price |

Payment terms | TT or L/C |

Monthly supply | 30000MT per month |

Application: | workshop, storeroom, roofing,kiosk... |

- Q: What is the (balanced) chemical equation for steel?

- This Site Might Help You. RE: Chemical equation for steel? What is the (balanced) chemical equation for steel?

- Q: What is the standard length of steel coils?

- The standard length of steel coils can vary depending on the specific industry and application. However, common standard lengths range from 1000 to 6000 millimeters or 3 to 20 feet.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Category Material Density Metal Steel, tool 7.715 Metal Wrought Iron 7.75 Metal Carbon Tool Steel 7.82 Metal Steel, cold-drawn 7.83 Metal Carbon Steel 7.84 Metal Steel, C1020, HR 7.85 Metal Pure Iron 7.86 Metal Soft Steel (0.06% C) 7.87 Metal Stainless Steel, 304 8.03 Metal Stainless 18Cr-8Ni 8.03 I looked up specific gravity mild steel. This might get you pointed in the right direction.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are processed for cutting to length or blanking through a series of steps. First, the coil is uncoiled and flattened to remove any inherent deformities. Then, the edges are trimmed to ensure uniform width and straightness. Next, the coil is fed into a leveling machine to eliminate any remaining inconsistencies in thickness. Once leveled, the steel is conveyed to a cutting machine where it is precisely cut into individual sheets of desired length or blanks. These sheets or blanks are then stacked and prepared for further fabrication or distribution.

- Q: How are steel coils used in the production of metal panels?

- Metal panels require steel coils as an essential component in their production. These coils, typically made from high-quality steel, act as the raw material for manufacturing different types of metal panels. To initiate the production process, specialized machinery is used to unroll and flatten the steel coils. This process guarantees a consistent and uniform thickness throughout the sheet. Following this, the flattened steel is cut into the desired length and width, depending on the specific requirements of the metal panel being produced. After the steel has been cut, it undergoes further processing, including cleaning and coating. This step aims to eliminate any impurities and safeguard the steel against corrosion or damage. The coating also enhances the appearance of the metal panel and provides additional durability and longevity. Once the cleaning and coating process is complete, the steel sheets are shaped into the desired form using various techniques such as roll forming or stamping. This enables the creation of diverse metal panels, including roofing panels, wall panels, and decorative panels, among others. The selection of steel coils for metal panel production is based on their strength, durability, and versatility. Steel is renowned for its exceptional structural properties, making it the ideal material for constructing sturdy and long-lasting metal panels. Moreover, steel exhibits high resistance against environmental factors like extreme weather conditions, further enhancing the durability of the metal panels. In conclusion, steel coils play a critical role in the production of metal panels by serving as the raw material and undergoing various processes to ensure quality and durability. The utilization of steel coils enables the production of a wide range of metal panels suitable for various industries and applications.

- Q: I'm going to buy a guitar for beginners and i wondered what strings are better steel or nylon?

- I urge you to read the answer from OU again and ignore the others - who obviously haven't got the first clue of what they're talking about. You pick the guitar for the type of music (and sound) you're after. You can play basically everything on a steel string that you can on a nylon string, plus a whole lot more... And no, a classical guitar is NOT easier to play than a well adjusted steel string with light strings - in fact it's the opposite. A classical guitar has a wide, flat fingerboard, something which makes chords much harder to play. Furhermore, the scale is longer (the scale is the distance between the nut and bridge - the length of the vibrating string if you will). This longer scale increase the distance between the fret (increasing the reach), and also increase the string tension. Finally, the action (string height) is larger on a classical/nylon string guitar as opposed to a steel string guitar which has been properly adjusted. Most guitars off the shelf have an inferior set up for a beginner, and this is why many have this funny idea that a steel string is much harder to play. You may also want to check out guitar body sizes (steel string) that is smaller than the large Jumbo or Dreadnought varieties. In essence, if you play classical music, or classical finger style guitar - choose a nylon string instrument. If not, then get a steel string and have it properly adjusted. Make sure you try out a lot of models as the necks, bodies, woods etc, differ a lot.

- Q: What are the different methods of coil leveling?

- There are several methods of coil leveling that are commonly used in various industries. These methods include: 1. Roller leveling: This method involves passing the coil through a series of rollers that apply pressure and gradually flatten the coil. The rollers can be adjusted to apply varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: In this method, the coil is subjected to tension forces that elongate the material and remove the internal stresses. The coil is passed through a series of rollers while being stretched, which results in a more uniform and flat surface. 3. Temper leveling: This method involves heating the coil to a specific temperature and then cooling it rapidly. The rapid cooling process helps to equalize the stresses within the coil and improve its flatness. Temper leveling is often used for high-strength steels. 4. Roller leveling with leveling rolls: This method uses additional leveling rolls that are positioned above and below the main leveling rollers. The leveling rolls apply pressure to specific areas of the coil to correct any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil while it is being processed. The tension helps to straighten and flatten the material, resulting in a more even and flat surface. 6. Precision leveling: This method is used for high-precision applications where extremely flat and uniform coils are required. Precision leveling involves a combination of roller leveling, stretch leveling, and other corrective measures to achieve the desired level of flatness. Each of these methods has its own advantages and limitations, and the choice of method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: How are steel coils used in the production of agricultural machinery parts?

- Steel coils are commonly used in the production of agricultural machinery parts due to their strength and versatility. Agricultural machinery parts such as blades, plowshares, and cultivator tines require materials that are durable and able to withstand harsh conditions. Steel coils provide the necessary strength and durability to these parts. The process starts with the steel coils being unwound and cut into the desired lengths. These lengths are then fed into a machine where they undergo various shaping processes such as bending, cutting, and stamping. This allows the steel to be formed into the specific shapes required for agricultural machinery parts. Once the desired shape is achieved, the steel parts are often heat-treated to enhance their strength and durability. This process involves heating the parts to high temperatures and then rapidly cooling them. Heat treatment increases the hardness and toughness of the steel, making it more resistant to wear and tear in the agricultural field. After heat treatment, the steel parts may undergo additional processes such as welding, surface coating, or painting, depending on the specific requirements of the machinery. These processes further enhance the durability and longevity of the parts. Overall, steel coils play a crucial role in the production of agricultural machinery parts by providing the necessary strength, durability, and versatility. The use of steel coils ensures that these parts can withstand the demanding conditions of agricultural operations, ultimately contributing to the efficiency and productivity of the farming industry.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: What are the common coil storage conditions?

- The common coil storage conditions include storing coils in a dry and clean area, away from direct sunlight and extreme temperature variations, and ensuring proper ventilation to prevent moisture buildup. It is also important to stack the coils properly, avoiding any damage or deformations, and to label and organize them for easy identification and retrieval.

Send your message to us

PPGI Anti-Finger Print Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords