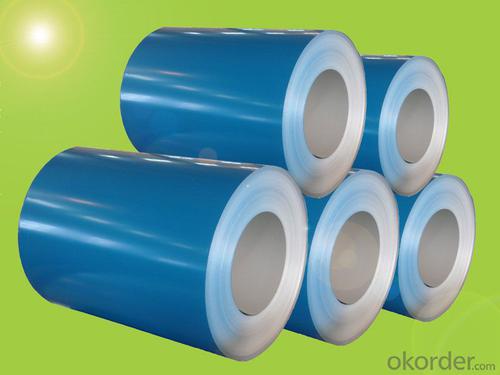

High Quality PPGI

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

super weather resistance and durability , also the pattern is capable to bring about plenty of effects of multilayer, parallax and 3D effect.

Application

It is the perfect building material in construction for making steel roofing/suspended ceiling, office partition, Sandwich panel, insulation panel, corrugate sheet, facade wall,rolling doors, T-bar, garage door and shutters etc.

Structure of Cross-section

Items | Thickness | Type | Features |

Protection Film | 50μm | polyethylene | Protecting from scratches and |

Finished Coat | 10μm | PVDF | Protecting printed layer and enhances |

Print | ≦1μm | Ink, Polyester | Various printing patterns,3 colors overprint |

Top Coat | 20μm | Polyester Fluorine | Chemical resistance, formability and |

Primer Coat | 5μm | Polyester | workability, corrosion resistance and |

Chemical Treatment | ≦1μm | Chromate | Good adhesion and corrosion resistance |

Substrate | 0.2-1.2mm | GI.GL.AL | GI.GL,AL |

Chemical Treatment | ≦1μm | Chromate | Good adhesion and corrosion resistance |

Back Coat | 5μm | Epoxy | corrosion resistance and adhesion to the |

- Q: What are the different coil coatings available for steel coils?

- There are several different coil coatings available for steel coils, including polyester, silicone modified polyester (SMP), polyvinylidene difluoride (PVDF), plastisol, and epoxy. Each coating has its own unique properties and advantages, such as durability, weather resistance, and color retention, allowing for a wide range of applications in various industries.

- Q: How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of careful selection of raw materials, closely monitored manufacturing processes, and rigorous quality control measures. This includes conducting regular inspections and tests at various stages of production to ensure that the steel coils meet the required specifications and standards. Additionally, implementing proper storage and handling procedures, as well as adhering to industry best practices, can help maintain the quality of steel coils throughout their lifecycle.

- Q: What is galvanized steel coil?

- Galvanized steel coil refers to a steel sheet that has been coated with a protective layer of zinc to prevent corrosion and increase its durability. This process, known as galvanization, involves immersing the steel coil in a bath of molten zinc, creating a bond that forms a protective barrier against moisture, chemicals, and other elements that can cause rusting. The result is a versatile and long-lasting material commonly used in construction, automotive, and manufacturing industries.

- Q: I made a wood crossbow body but all I need is a bow which I want to be metal. I've used a thin steel sheet that I cut to appropriate size but when it bent with the string strung, it never went to original shape after being shot. I used a slightly thicker and it wouldn't bend at all. Anybody know what thickness and type to use? Any real answers are very appreciated. Thanks.

- So i do know way more about compound bows than I do about crossbows, but i'm going to enterprise an opinion. For my part, i would probably lean toward the compound bow. A part of it's only that i like them higher. However, moreover to that, more often than not when you find yourself hunting you will carry the crossbow loaded, on the grounds that the are typically awkward to load when you have the shot. If you're hunting from a blind or from a tree stand (and might figure out easy methods to load the item whilst you're up there) that's almost always ok. But when you need to tote a crossbow round whilst it's loaded, that may be a bit dicier proposition. Most crossbow safeties are lovely crude making the likelihood of by chance firing one alot bigger than with a rifle. Now, to the plus facet, a crossbow has essentially the entire upside of firing a rifle - best accuracy, same ergonomics, can run a scope on them. Without the downside - no real recoil, no longer too loud and you simply have a lovely excellent trigger on about any of them. Compounds are way more work. Plus it is much tougher to be accurate under stress with a compound than a crossbow. Regarding the protection? Don't particularly find out about that. After I was once doing shooting alot of archery, my 3 - D bow for outdoor stuff was once at ninety two pounds with a fifty five% letoff. My goal bow was once round 60. I had to pretty on the whole take care of string stretch, and tuning with the three - D bow. So i'd expect a crossbow to be in that regional. 5 hours to your nearest Bass pro? Good for a crossbow perhaps it's valued at it because no longer too many places raise them. Nonetheless, should you do back to a compound bow it appears rough to feel that would be your nearest archery professional shop. Thinkingblade

- Q: How are steel coils processed for edge trimming or slitting during processing?

- Steel coils are processed for edge trimming or slitting during processing by using specialized machinery. The coils are uncoiled and fed through a slitting machine, which cuts the coil into narrower strips. These strips are then passed through an edge trimming machine, which removes any irregularities or excess material from the edges. This process helps to ensure that the steel coils meet the desired specifications and are ready for further processing or use in various industries.

- Q: How are steel coils used in the production of automobile frames?

- Automobile frames rely heavily on steel coils, which are indispensable for their production. These coils, crafted from top-notch steel, undergo a process of uncoiling before being fed into a stamping press, where they assume various forms, constituting parts of the frame. The presence of steel coils is crucial as they furnish the frame with the requisite strength and rigidity, ensuring it can bear the vehicle's weight and maintain structural integrity. Once shaped, the coils are frequently welded together to construct the frame structure. This welding procedure securely binds the individual components, guaranteeing that the frame can endure the forces and strains encountered during the vehicle's operation. Utilizing steel coils in the production of automobile frames also allows for design flexibility, as they can be effortlessly shaped and manipulated to fulfill specific requirements. Moreover, steel coils possess exceptional durability and corrosion resistance, rendering them ideal for automotive applications. Frames fashioned from these coils are not only robust and dependable but also capable of withstanding harsh conditions and road vibrations. This not only enhances the vehicle's safety but also contributes to its longevity and overall performance. Steel coils also find use in other critical vehicle components, including suspension systems, chassis, and body panels. Their versatility, strength, and cost-effectiveness make them a favored choice in the automotive industry. Overall, the incorporation of steel coils in automobile frame production plays a significant role in guaranteeing the safety, durability, and performance of modern vehicles.

- Q: What are the different methods of galvanizing steel coils?

- There are three main methods of galvanizing steel coils: hot-dip galvanizing, electro-galvanizing, and continuous galvanizing. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc, providing a thick and durable coating. Electro-galvanizing uses an electrical current to deposit a thin layer of zinc onto the steel surface. Continuous galvanizing is a process where the steel coil is continuously passed through a series of zinc baths, resulting in a uniform coating.

- Q: What are the different methods of surface cleaning for steel coils?

- There are several different methods available for surface cleaning of steel coils. The choice of method depends on the specific requirements and conditions. 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, sanding discs, or abrasive pads to physically remove dirt, rust, or other contaminants from the surface of the steel coils. It is commonly used for light cleaning and can be done manually or with the help of automated equipment. 2. Chemical Cleaning: Chemical cleaning involves the use of various cleaning agents or solvents to dissolve or loosen contaminants from the surface of steel coils. This method is effective for removing oil, grease, or stubborn dirt. Different chemicals can be used depending on the type of contaminants and the desired level of cleaning. It is important to follow safety guidelines and use appropriate protective equipment when using chemical cleaners. 3. Power Washing: Power washing or pressure washing utilizes a high-pressure water jet to remove loose particles, dirt, or contaminants from the surface of steel coils. This method is effective for large-scale cleaning and can be combined with chemical cleaners for enhanced results. It is important to adjust the water pressure according to the type of surface and use appropriate nozzles to prevent damage. 4. Pickling: Pickling is a chemical cleaning method that involves the immersion of steel coils in an acidic solution, typically a mixture of hydrochloric acid and sulfuric acid. This process removes scale, oxides, and other impurities from the surface of the steel. Pickling is commonly used for heavy-duty cleaning and preparation of steel coils before further processing or coating. 5. Electrolytic Cleaning: Electrolytic cleaning utilizes an electric current to remove contaminants from the surface of steel coils. The coils are immersed in an electrolyte solution, and the application of a direct current causes the contaminants to dissolve or dislodge from the surface. This method is particularly effective for removing rust or corrosion and can be used in conjunction with other cleaning methods. It is important to consider factors such as the type and condition of the steel coils, the level of cleanliness required, and any specific industry standards or regulations when choosing the appropriate method of surface cleaning. Regular maintenance and cleaning of steel coils are essential to ensure their longevity, performance, and resistance to corrosion.

- Q: Where can a find a steel scrubber. Its great to clean cooking vessels. Would be great if someone gives me an idea. I did not find it at CVS, but was in a hurry, will try again tomorrow.

- I posted this earlier to a similar question... Really burnt on gunk in the bottom like milk or blackened food can easily be cleaned out of stainless steel pots and pans by sprinkling baking soda in the bottom, covering with vinegar, let simmer with a little water for 5 min. Let cool, scrub out with a vinyl scrubby. or I use a lot of stainless steel for cooking and over the years have found a very inexpensive solution to cleaning them especially the ones with burnt food stuck at the bottom. I use Used fabric softner sheets (sheets that i have already used in the dryer for my clothes) and have them soak in water in the dirty pan overnight. Next morning i use the same sheet as scrubber to clean the pan and all the burnt food comes off easily leaving a new look to the pan. Try it this works.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they serve as the core material for the door's structure, providing strength and durability. The coils are typically shaped, cut, and molded into the desired door shape, then combined with fire-resistant materials such as gypsum or mineral wool to enhance the door's fire resistance.

Send your message to us

High Quality PPGI

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords