Woven Non Woven Geotextile Professional Waterproof Geotextiles

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Woven Geotextile Professioal Waterproof Geotextiles

Desciriptions:

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

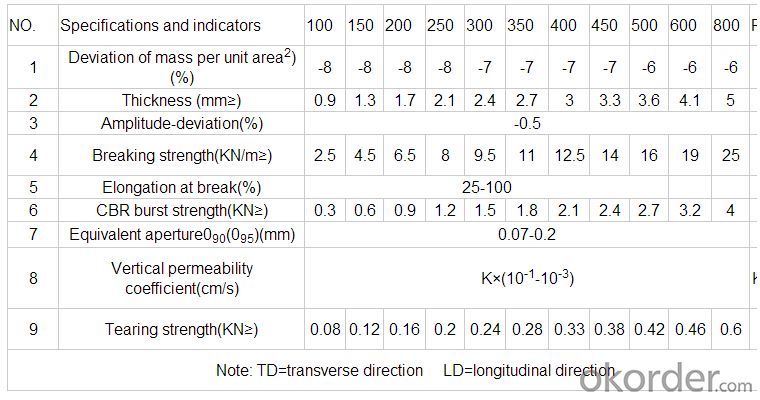

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

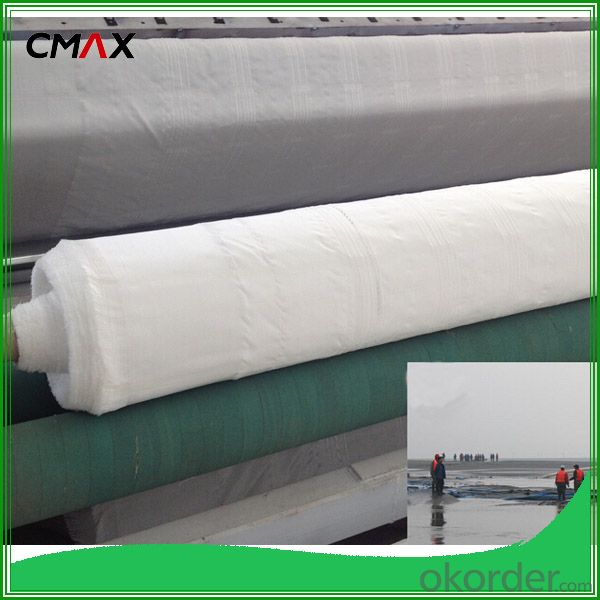

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the key factors affecting the permeability of geotextiles?

- The key factors affecting the permeability of geotextiles include the type and thickness of the geotextile, the size and distribution of the pores, the type of soil or material being filtered, the compaction of the soil, and the hydraulic gradient or pressure difference across the geotextile.

- Q: Hope expert expert to give the answer

- The ditch is the ditch at the edge of the roadbed, mainly used to collect and exclude a small amount of surface water within the roadbed and flow to the roadbed; drainage ditch is the ditch, cut ditch, roadbed near the water discharged to the bridge or road Where the ditch in the natural river ditch. Geotextile is a kind of synthetic high strength fiber material which is used to improve the bearing capacity of subgrade when the bearing capacity of the foundation is poor. It has many kinds of fiber materials. The purpose is to improve the bearing capacity and prevent the cracks in the road surface.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing additional strength and stability to the bags. They act as a barrier between the bag material and the surrounding soil, preventing soil erosion and enhancing the bag's structural integrity. The geotextiles distribute the load evenly across the bag, reducing stress concentrations and preventing the bags from bursting or tearing under heavy loads. Additionally, they allow for effective drainage of water, maintaining the bags' stability and preventing water accumulation that could potentially weaken the bags.

- Q: Now geotextile price quota how?

- 2017 geotextile price cheaper than last year, the current price of raw materials is relatively stable production. Geotextile classification of many, you ask more general, so no way to give you a detailed offer. Different technical requirements are uneven prices, but the overall price has come down, and is now the lowest price since 2017.

- Q: Geotextile fng-pet-250-400

- Fng-filament is a polyester filament spunbonded acupuncture non-woven geotextile Cloth 250g / ㎡-400g / ㎡.

- Q: Can geotextiles be used in erosion control blankets?

- Yes, geotextiles can be used in erosion control blankets. Geotextiles are often used as a material in erosion control blankets to provide stabilization and reinforcement against soil erosion. They help to prevent sediment runoff and promote vegetation growth, making them effective in erosion control applications.

- Q: Do you have to have a mattress on the geotextile?

- To see what in the place, for the filter, or for filtering. Huazhi geotechnical materials manufacturers to answer

- Q: Such as the title, the drawings are written on the weaving geotextile, the list is written on the blended geotextile cloth laying / 120g / m2 weaving geotextile, who can tell ah !!!!!!!!!! Urgent more

- Or geotextile ah

- Q: Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. They are commonly used as a protective layer between the reservoir's base and the impermeable lining material, helping to prevent punctures and enhance the overall durability and longevity of the lining system. Additionally, geotextiles can aid in filtration and drainage within the reservoir, improving its overall performance and functionality.

- Q: Can geotextiles be used in the construction of stormwater ponds?

- Yes, geotextiles can be used in the construction of stormwater ponds. Geotextiles are often used as a lining material to reinforce the pond's base and slopes, providing stability and preventing erosion. Additionally, geotextiles can act as a filter, preventing fine particles from entering the pond and improving water quality.

Send your message to us

Woven Non Woven Geotextile Professional Waterproof Geotextiles

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords