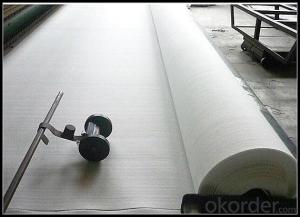

Road Construction Non-woven Geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

made of polyester or polypropylene fiber

good burying, hydrolyzation & corrosion resistibility

Density | Thickness | Breaking Strength | Elongation of Fracture | CBR Bursting Strength | Vertical Penetration Parameter | Equivalent Aperture |

g/m2 | mm | KN/m | % | KN | cm/s | O95 mm |

65 | 1.2 | 2.8 | 40 ~ 80 | 0.7 | K x (10-1 ~ 10-3)

(K = 1.0 ~ 9.9) | 0.07 ~ 0.2 |

75 | 1.4 | 3.3 | 0.8 | |||

100 | 1.6 | 5.0 | 0.95 | |||

150 | 1.52 | 7.5 | 1.5 | |||

160 | 2.0 | 8.5 | 1.60 | |||

200 | 2.4 | 11 | 2.10 | |||

250 | 2.8 | 14 | 2.60 | |||

300 | 3.4 | 16 | 3.20 | |||

400 | 4.0 | 21 | 4.0 | |||

500 | 4.5 | 25 | 4.8 |

- Q: Foam concrete for the roof cushion generally do much bulk ah

- First help you correct it, foam concrete used in the roof should be the role of thermal insulation, not as a cushion.

- Q: The top floor made waterproof playing cushion layer of how to do

- Roof leaking of the construction program: ? 1. Need to remove the previous waterproof, such as paint, coil, etc., if it is to do the mortar waterproof can not be eradicated.

- Q: The roof cushion is waterproof on the slope roof

- When the moisture generated by the ice dam into the external walls of the gap, the walls and insulation layer will become damp, which is the ideal environment for the breeding of mold.

- Q: Is the raft cushion waterproofing full of the cushion?

- The request is full. Raft foundation do not do waterproof mainly depends on the design of the groundwater level considerations, calculated if the floor itself to meet the requirements, you can not do, and not rigid to do.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be eradicated, but should pay attention not to damage.

- Q: Is foam concrete suitable for use as a cushion?

- Inappropriate. Bubble concrete is a new type of energy-saving and environmentally friendly building materials, which are widely used in wall materials, but there are still some defects, such as low strength, cracking, water absorption, as the cushion of its strength is not enough standard.

- Q: Large area ground concrete cushion seam Why is the separation of joints generally concrete

- Second, sub-grid seam set In order to reduce the total shrinkage and temperature stress of the large area waterproof layer, avoid the leakage of the waterproof layer due to the deformation of the structural layer and the change of the temperature and humidity, the waterproof layer should be divided according to the shape, size and structure of the flat roof, Stay sewn. The waterproof layer is divided into several squares.

- Q: How to build a fine stone concrete cushion?

- The main role of the cushion is to meet the requirements of the design elevation. In addition, the cushion to meet the sound insulation, insulation, insulation, slope and buried pipeline and other functional requirements and set a variety of levels.

- Q: Basement floor mattress dry to what degree can do coil waterproof?

- Third, the membrane waterproof in the construction should first do the basement floor of the waterproof, and then the membrane along the basement floor continuous paste to the outer surface of the wall. Basement floor waterproofing first in the foundation pouring C10 concrete cushion, the thickness of about 100mm. And then paste the membrane, and then in the coil to wear 20 thick 1: 3 cement mortar, and finally pouring reinforced concrete floor. The outer surface of the wall first wip 20mm thick 1: 3 cement mortar, cold base oil, and then paste the membrane, the membrane should be stitched paste, adjacent coil lap width of not less than 100mm. The top of the coil should be higher than the maximum water level of about 500mm, the outer side of the brick wall.

- Q: Maintenance time of the cushion on the roof of the building

- Concrete watering maintenance time: the use of Portland cement, ordinary Portland cement or slag Portland cement mixed with concrete, not less than 7d;

Send your message to us

Road Construction Non-woven Geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords