Manta Geotextil Rolo PP Woven Geotextile High Tensile Strength

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

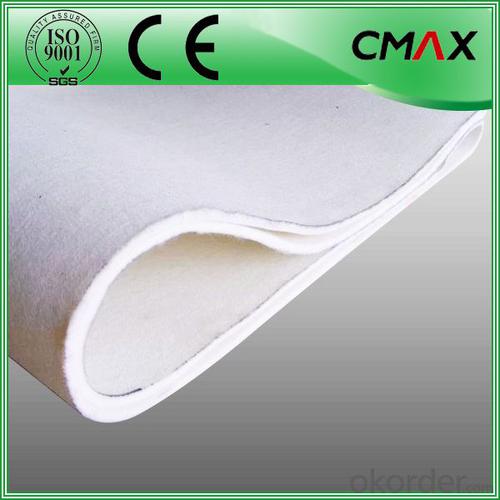

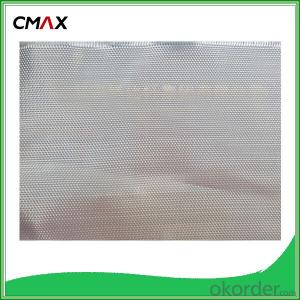

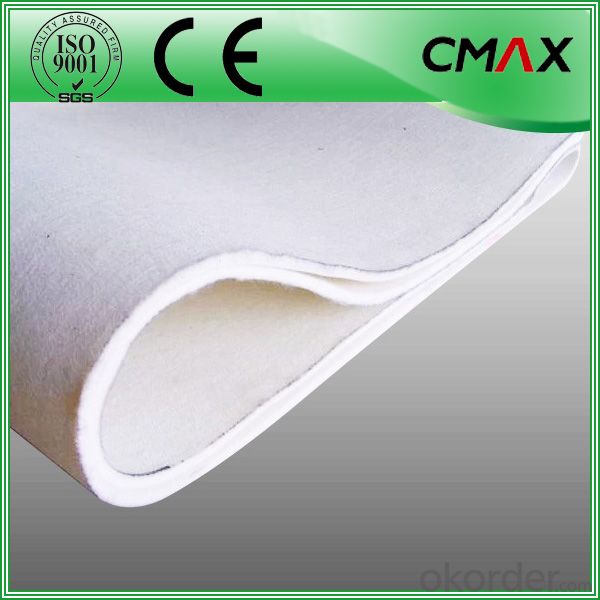

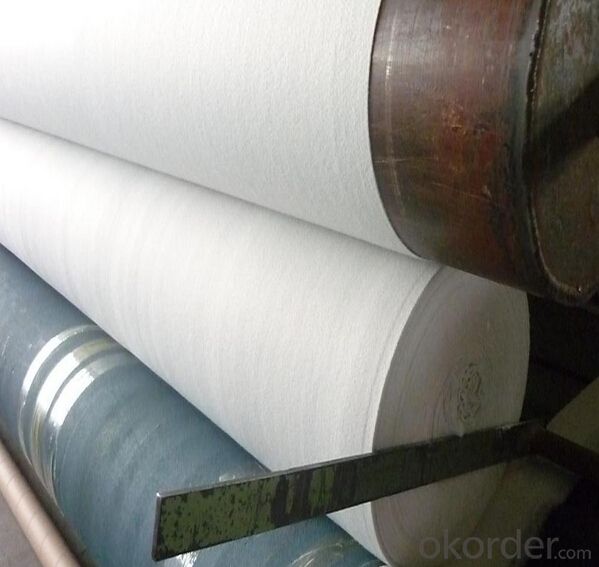

PP Woven Geotextile High Tensile Strength

Desciriptions:

PP Woven Geotextile High Tensile Strength are the preferred products for lining projects requiring low permeability , corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy , vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the benefits of using geotextiles in erosion control?

- Using geotextiles in erosion control offers several benefits. Firstly, geotextiles act as a barrier against soil movement and erosion, preventing the loss of valuable topsoil. They also help in stabilizing the soil by providing reinforcement and increasing its shear strength. Geotextiles allow water to pass through while retaining soil particles, thus reducing water runoff and sedimentation. Additionally, these materials are durable and resistant to degradation, ensuring long-term effectiveness in erosion control measures. By reducing erosion, geotextiles help protect natural habitats, prevent land degradation, and promote sustainable land management practices.

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by providing a strong and stable foundation. They act as a barrier between the soil and the wall, preventing erosion and soil movement. The geotextiles distribute the pressure from the soil evenly, increasing the stability and strength of the retaining wall. Additionally, they allow for proper drainage and filtration, reducing the build-up of water pressure behind the wall, which can cause structural failure.

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help prevent erosion around culverts by acting as a protective barrier that stabilizes the surrounding soil. They are installed to prevent soil movement and filter out any sediments, allowing water to flow freely while retaining the integrity of the soil structure. This helps to prevent erosion, maintain the stability of the culvert, and enhance its overall longevity.

- Q: How do geotextiles contribute to the durability of civil engineering structures?

- Geotextiles contribute to the durability of civil engineering structures by providing reinforcement, filtration, and separation. They act as a strong and stable barrier against soil erosion, preventing the movement and loss of soil particles. This reinforcement helps to maintain the integrity of the structure, especially in areas prone to high water flow or soil instability. Additionally, geotextiles act as a filtration layer, allowing water to pass through while preventing the migration of fine particles that could clog drainage systems. This filtration helps to maintain the functionality of the structure and prevent damage caused by water buildup. Furthermore, geotextiles aid in the separation of different layers of soil or materials, preventing mixing and maintaining the structural stability of the construction. Overall, geotextiles play a vital role in enhancing the durability and longevity of civil engineering structures.

- Q: Can geotextiles be used in railway track bed stabilization?

- Yes, geotextiles can be used in railway track bed stabilization. They are commonly used to improve the stability and performance of the track bed by providing separation, filtration, and reinforcement. Geotextiles help to prevent the mixing and migration of different layers of the track bed, enhance drainage, increase load-bearing capacity, and reduce the risk of track settlement and deformation. Overall, geotextiles play a crucial role in maintaining the long-term stability and durability of railway tracks.

- Q: Geotextile what are the specifications of the ah?

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q: Can geotextiles be used in shoreline protection?

- Yes, geotextiles can be used in shoreline protection. Geotextiles are permeable fabrics that can be placed along shorelines to control erosion and stabilize the soil. They act as a barrier that prevents the loss of sediment while allowing water to pass through. This helps to protect the shoreline from wave action and reduce overall erosion.

- Q: Tunnel without sand concrete, geotextile, seepage blind pipe construction sequence

- In accordance with the order of seawater blind pipe geotextile sandless concrete, I specialize in producing geotextile materials

- Q: What are the common problems encountered during geotextile installation?

- Some common problems encountered during geotextile installation include improper placement or alignment, inadequate tensioning or anchoring, damage to the geotextile during installation, inadequate overlap or seam strength, and difficulties in handling or maneuvering the geotextile due to its size or weight.

- Q: What are the limitations of geotextiles?

- Geotextiles have certain limitations that need to be considered. Firstly, they are not suitable for high load-bearing applications and may require additional reinforcement. Secondly, they may degrade over time due to exposure to UV radiation, leading to a decrease in their effectiveness. Additionally, geotextiles may not be effective in controlling fine particles or preventing the growth of vegetation in certain scenarios. Lastly, they may be susceptible to damage during installation or due to punctures and tearing, requiring careful handling.

Send your message to us

Manta Geotextil Rolo PP Woven Geotextile High Tensile Strength

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords