Geotextile Menards PP Nonwoven Geotextile with High Strength for Road Construction and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

1. Specifications for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

Material | PP(polypropylene) or PET(polyester) |

Technics/process | Needle punched / thermally bonded |

Specification | 100g/m-1300g/m2 |

Width | 1m6m(as you demand) |

Length | 100m(as you demand) |

Colour | White, black |

Packing | PE film and woven cloth |

Load | According to your specification |

Payment terms | T/T or L/C |

Delivery time | Within 3 weeks |

Application | Geotextiles with various indicators of quality, with good stress -- strain and toughness, seepage performance and uniformity, and width, etc., And is applicable to roads, water, rail, mining dams, rivers, airports and other civil engineering, anyone in the works played reinforcement, segregation, filtration, filtration, drainage, and then extend the project life, reduced cost and easy construction, and it is easy to ensure the quality of the project. |

2. Property for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

1). Good air and water permeability-interspace in the fibers made it favorable water permeability.

2). Corrosion resistant-geotextile is made from polyester, featuring resistance to acid and alkali ,non-corroding,no worm-eaten,anti-oxidation.

3). Good water transmissibility and filtration- it can form drainage channels inside soil mass to drain redundant water and air out of the soil mass.

4). High intensity-geotextile can keep sufficient strength and elongation in dry and wet condition due to the use of plastic fiber.

5). Easy construction,low weight,easy operation,simple construction

3. Property for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

1). Isolation

Short fiber needle punched geotextile can prevent the mixture of construction

materials featuring different physical properties (such as soil mass and sandstone,soil mass and concrete)

2). Filtration

Its good water and air permeability let water flow through it so as to effectively control

sandrock running down.

3). Reinforcement

Geotextile helps to enhance the soil mass tensile strength and non-deformability and structural stability so as to improve soil mass quality.

4). Protection

It can effectively make the concentrated stress diffuse,transfer or decompound,and guard the soil mass against the destruction of external force.

5). Anti-puncture

Combine with geomembrane and form compound waterproofing material to act a part of anti-puncture.

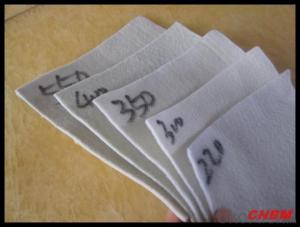

4. Photos for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

- Q: What are the different functions of geotextiles in geoenvironmental engineering?

- Geotextiles serve various functions in geoenvironmental engineering, including erosion control, soil stabilization, drainage, filtration, and reinforcement. These materials prevent soil erosion by acting as a barrier against water flow and wind forces. They also stabilize soil by improving its mechanical properties, preventing soil movement and settlement. Geotextiles facilitate drainage by allowing water to pass through while retaining soil particles. They serve as a filtration layer, separating different soil layers and preventing the migration of fine particles. Additionally, geotextiles are used for reinforcement purposes, enhancing the strength and load-bearing capacity of soil structures.

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing reinforcement and stability. They help to prevent soil erosion by acting as a barrier against water flow and sediment movement. Additionally, geotextiles assist in distributing the load evenly across the slope, reducing the risk of structural failure.

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help prevent erosion around culverts by acting as a protective barrier that stabilizes the surrounding soil. They are installed to prevent soil movement and filter out any sediments, allowing water to flow freely while retaining the integrity of the soil structure. This helps to prevent erosion, maintain the stability of the culvert, and enhance its overall longevity.

- Q: Seepage geotextile symbol

- I produce geotextile materials

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. Geotextiles are commonly used to reinforce and stabilize soil by providing strength, preventing erosion, and promoting drainage. They are often used in various civil engineering applications such as road construction, embankments, and retaining walls to improve the stability and longevity of the soil.

- Q: Are geotextiles commonly used in agriculture?

- Yes, geotextiles are commonly used in agriculture. Geotextiles have multiple applications in the agricultural industry, including soil stabilization, erosion control, weed suppression, and drainage management. They help improve soil quality, reduce erosion, and enhance crop growth, making them a valuable tool for many farmers and agricultural practices.

- Q: Are geotextiles resistant to hydraulic shear stress?

- Yes, geotextiles are generally resistant to hydraulic shear stress. They have a high tensile strength and are designed to withstand the forces exerted by flowing water or other hydraulic conditions, making them effective in erosion control and soil stabilization applications.

- Q: Can geotextiles be used in shoreline protection projects?

- Yes, geotextiles can be used in shoreline protection projects. Geotextiles are often utilized in coastal erosion control and shoreline stabilization efforts as they can help to prevent soil erosion, control sediment movement, and enhance the stability of shoreline structures.

- Q: GB / T geotextile sampling sampling frequency, 100 volumes equal to the number of square meters?

- Geotextile width is usually 6 meters long, 50 meters long or 100 meters. A roll area of 300 square meters or 600 square meters. 100 volumes are 300 * 100 square meters, or 600 * 100 square meters.

- Q: Geotextile with glue can stick cement wall

- With the wind oil fine soaked, wipe with a rag off.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geotextile Menards PP Nonwoven Geotextile with High Strength for Road Construction and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords