High Strength PP Woven Geotextile Geotextile Manufacturers/polypropylene woven geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

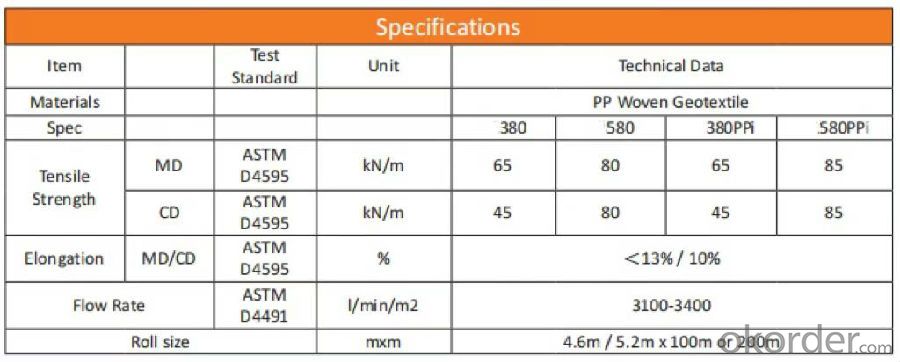

High Strength PP Woven Geotextile Description:

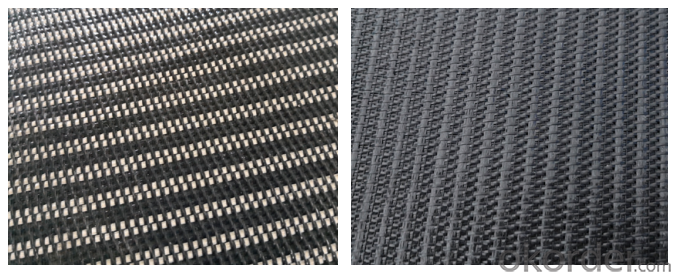

CNBM Geotextile is manufactured from woven high tenacity polypropylene multifilament yarns, which are woven into a stable network such that the yarns retain their relative position. CNBM Geotextile is inert to biological degradation and resistant to naturally encountered chemicals, alkalis, and acids etc. Used in coastal protection,reinforced & dewater etc.

Product Popular Specification:

PP High Strength Woven Geotextile Features:

High tensile strength at low elongation

High modulus

Excellent resistance to mineral acids

Good durability to ensure structure safety

Excellent chemical resistance, even in alkaline soils

High quality and durability to ensure structure safety

High mechanical performance

High permittivity and water flow rates

Proven performance for most stabilization and receforcement applications

Extensive range of size, thickness and grades

Easy handling and installation

Ensured quality

Cost-effective

Fast delivery

PP Woven Geotextile Application:

PP woven geotextile is cost effective and availbale in various tensile strengths, woven open sizes to meet extensive project stabilization and reincrocement requirements.

Earthwork Construction

Steep side slope reinforcement

Embankment stablization and reonforcement

Bridging over sinkholes

Roadway and Railway Construction

Base Reinforcement

Subgrade stabilization

Water infrastructure

Marine and coastal construction

Seawalls and breakwaters

Riverbank and channel protection

Airport runway

Beach reclamation

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help with pipeline protection?

- Geotextiles help with pipeline protection by acting as a barrier between the pipeline and the surrounding soil, preventing soil erosion and the formation of voids around the pipeline. They also provide additional support and reinforcement to the pipeline, reducing the risk of damage from external forces such as ground movement or heavy traffic. Furthermore, geotextiles can help with filtration, allowing water to pass through while preventing the migration of fine particles that could clog the pipeline. Overall, geotextiles enhance the longevity and structural integrity of pipelines, ensuring their safe and efficient operation.

- Q: How do geotextiles help with filtration in geosynthetic clay liners?

- Geotextiles help with filtration in geosynthetic clay liners by serving as a barrier between the clay liner and the surrounding soil. They prevent the migration of fine particles from the soil into the clay liner, ensuring efficient filtration and preventing clogging of the clay liner.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles are commonly used as a separation and filtration layer in geocell mattress systems to prevent soil migration, enhance drainage, and provide stability. They help distribute loads evenly and improve the overall performance of the geocell mattress system.

- Q: Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are often used as a filter or separation layer behind retaining walls to prevent the migration of fine soil particles and provide drainage. They help in distributing the load and reducing the pressure on the wall, increasing its stability and lifespan.

- Q: How to deal with the use of geotextiles under the roof

- Drainage board, geogrid

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. So to speak, long-term vision of the words must be solidly do every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem.

- Q: Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q: What is the place of attention for the laying of geotextiles?

- (1) the use of the use of buried type: cover the thickness should not be less than 30cm (2) refurbishment system should be: cushion, impermeable layer, transition layer, protective layer composition. (3) soil to be solid, to avoid uneven subsidence, cracks, anti-seepage within the turf, root to clear. And the surface of the membrane with a small particle size of sand or clay as a protective layer. (4) laying the geomembrane do not pull too tight, both ends of the soil into the corrugated part of the soil is better, especially with the rigid material anchoring, should leave a certain amount of expansion and contraction. (5) construction, should avoid stones,

- Q: What are the different geotextile durability testing standards?

- There are several different geotextile durability testing standards, including ASTM D4355, ISO 12956, and ISO 12236. These standards evaluate the durability and performance of geotextiles by subjecting them to various mechanical, chemical, and environmental tests.

- Q: How do geotextiles improve the performance of geomembranes?

- Geotextiles improve the performance of geomembranes by providing separation, filtration, and reinforcement functions. They prevent the mixing of different soil layers, enhance drainage, and distribute loads more evenly. Additionally, geotextiles protect the geomembranes from punctures and abrasions, thereby increasing their durability and lifespan.

Send your message to us

High Strength PP Woven Geotextile Geotextile Manufacturers/polypropylene woven geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords