PP woven Geotextile fabric price for highway 600g/m2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Technical Properties Woven Polypropylene (Pp) Geotextile

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |

Break Strength KN/m≥(LD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Break Strength KN/m≥(TD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Break Elongation %≤(LD,TD) | 28 | ||||||

Trapozoidal Tear Strength KN≥(LD) | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical Permeability Coefficient (cm/s) | 10-1~10-3 | ||||||

Sieve Size(O95.)mm | 0.08-0.5 | ||||||

Mass Weight (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Variation % | ±10 | ||||||

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

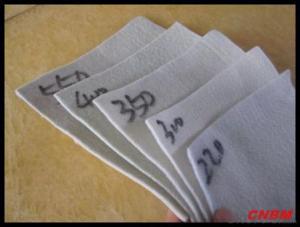

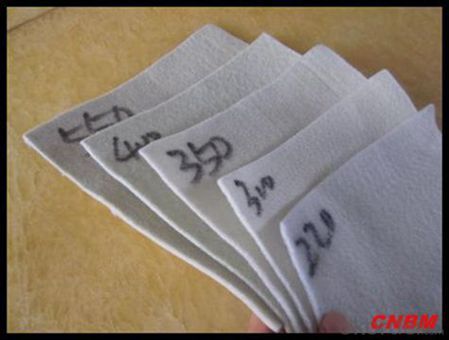

A: Yes, please check the pictures:

- Q: How do geotextiles help with soil reinforcement in pavement systems?

- Geotextiles provide soil reinforcement in pavement systems by acting as a barrier between different layers of soil, preventing their intermixing and maintaining the stability of the pavement. They distribute the load more evenly, reducing the potential for soil settlement and rutting. Additionally, geotextiles enhance the overall strength and durability of the pavement system by providing tensile strength and preventing the migration of fine particles, ultimately improving the performance and lifespan of the pavement.

- Q: 200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How many grams of geotextiles on the top of the garage

- Drainage board is generally 1000 grams 20MM, geotextiles generally require 250 grams, you need to contact Huazhi geotechnical materials manufacturers to answer your questions

- Q: Where to sell geotextiles

- Those who produce geotextile manufacturers are selling black geotextile. Black geotextile according to the use of a lot of specifications, the price difference is very large. The weight per square meter between about 50-1000g grams, the weight of different unit price is different, the inquiry directly asked how much money per ton. According to the use of distinction between the current market price per ton price between 5,000 yuan - yuan. For the conservation, isolation, insulation of the geotextile the cheapest. In the 5000 yuan / ton between. For the filter, soft base treatment, slope protection, reinforced decoration, and other purposes of the black geotextile most expensive in - yuan / ton. The same black color, but different uses, production processes and production costs are not the same.

- Q: What are the considerations for geotextile selection in landfill projects?

- When selecting geotextiles for landfill projects, several considerations must be taken into account. These include the desired function of the geotextile, such as separation, filtration, or drainage. The physical properties of the geotextile, such as tensile strength, puncture resistance, and thickness, are also important factors to consider. Additionally, the site conditions, such as soil type, water table, and potential for chemical exposure, should be evaluated to ensure the geotextile's compatibility. Lastly, the long-term durability and cost-effectiveness of the geotextile should be considered to ensure its suitability for the landfill project.

- Q: Can the geotextile function be a filter?

- Hello, geotextile is the most important role is to filter, some of the above works of water filter material is mainly used geotextile, geotextile price is relatively low, relatively high tensile strength, can play a filtering effect. Zhongrui geotech Zhang Mingchao answer for you.

- Q: I would like to make the beach bigger along the lake in our backyard. I am hoping to do it myself for my husband for father's day. I need suggestions on the best way to do this as a one women team.

- "Quilting fabric" is typically 100% cotton. Quilters prefer to use cotton over other fabrics. Sewing fabric can be any type of fabric ie: cotton, flannel, polyester, knit and others. Using "quilting fabric" is fine for a skirt as cotton is a good choice. I've sewn quite a few of my daughters clothes with it and it wears really well. The variety of patterns and colors is usually fantastic.

- Q: Are geotextiles resistant to fire?

- No, geotextiles are not naturally resistant to fire.

- Q: Pool with geomembrane but not long enough to stick to the pool side

- Should be geomembrane professional welding machine welding, not long enough, then do not seepage effect, I am specializing in the production of geotextile geomembrane and other materials, wish smooth

- Q: How do geotextiles help in separating different soil layers?

- Geotextiles help in separating different soil layers by acting as a barrier between the layers, preventing their intermixing. The geotextiles have a permeable structure that allows water to pass through while retaining the soil particles, thus maintaining the integrity of each layer. This separation is crucial in various applications, such as road construction, landscaping, and erosion control, as it enhances the stability and performance of the soil layers.

Send your message to us

PP woven Geotextile fabric price for highway 600g/m2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords